Maintenance

2751−4/A1

RT-flex50-D

Wärtsilä Switzerland Ltd

1/ 2

Tools:

1 Feeler gauge 94122

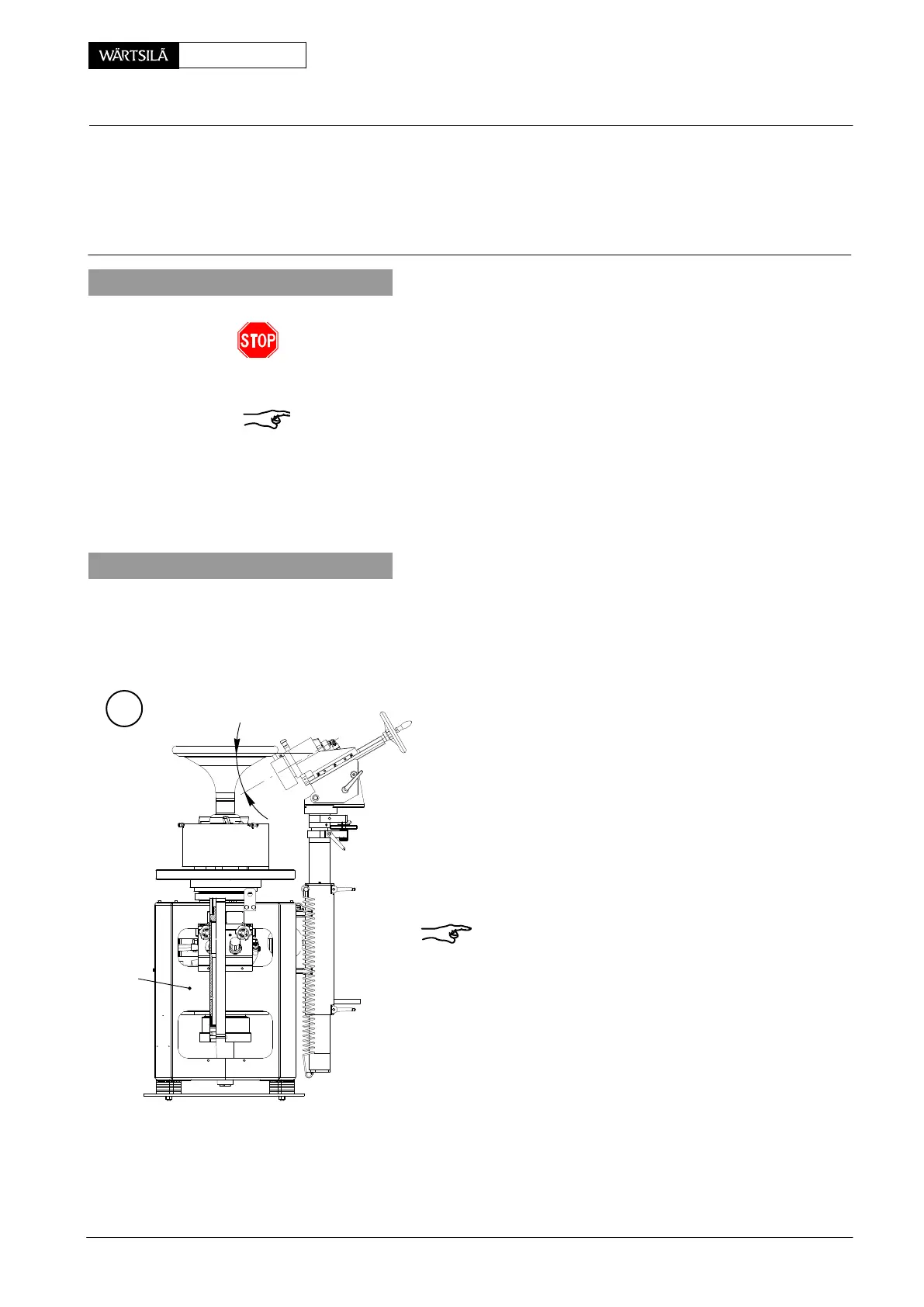

1 Valve grinding device 94291

1 Gauge 94292

1. General

Grinding in a valve together with its valve seat with grinding paste is not permitted.

Valves which have had the seating surfaces badly damaged by pitting or corrosion

have to be reground by machine. It is strongly recommended that a suitable grind-

ing machine 94291 be made available.

Remark: A valve spindle with missing rotation wing may not be reground. The

wing hub must be shrink-fitted on the valve shaft by heating it to 480 _C. Grinding

may first begin after the whole unit has cooled down.

The machines from the makers HUNGER and CHRIS - MARINE are well proven

for valve grinding and can also be ordered directly from Wärtsilä Switzerland Ltd,

Winterthur.

2. Grinding the seating surface

D Only as little material as necessary should b

ground off the valve seating surface to provide

clean and smooth finished surface.

Only grind with cooling (wet).

D In order to avoid the appearance of chatter mark

on the seating surface, the grinding machin

should be placed in an area which is free of vibra

tion from running machinery or engines, etc.

necessary the grinding machine should be stoo

on a rubber mat.

Remark: For the application of the grinding device re

fer to the operating instructions.

A

a

016.744/08

SEATING SURFACE

ANGLE ON VALVE

94291

+8’

a = 30 _

+10’

xhaust Valve

rinding the Seating Surface on the Valve Head

2010-08

Loading...

Loading...