Maintenance1132−2/A1 RT-flex50-D

Wärtsilä Switzerland Ltd

8/ 17

5. Turning out and removal of lower bearing shells

Attention! Never remove two neighbouring lower bearing shells at the same time!

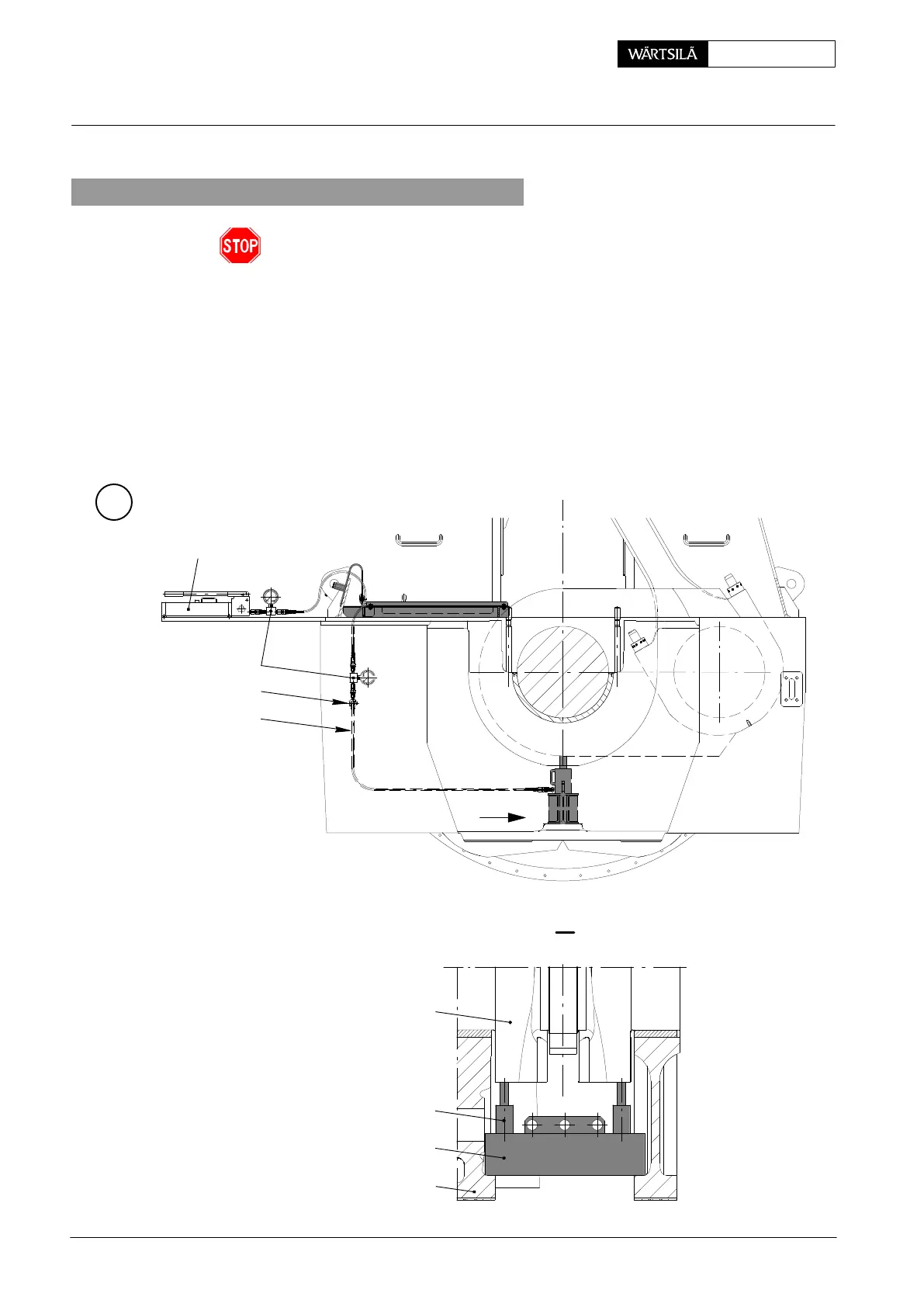

D For the removal of lower bearing shells No. 1 and 2, the flywheel must in addi-

tion be pressed up with jack 16. To protect the flywheel toothing, put a copper

or aluminium plate between the jack and the flywheel (Fig. ’I’).

5.1 Fitting the hydraulic jacks

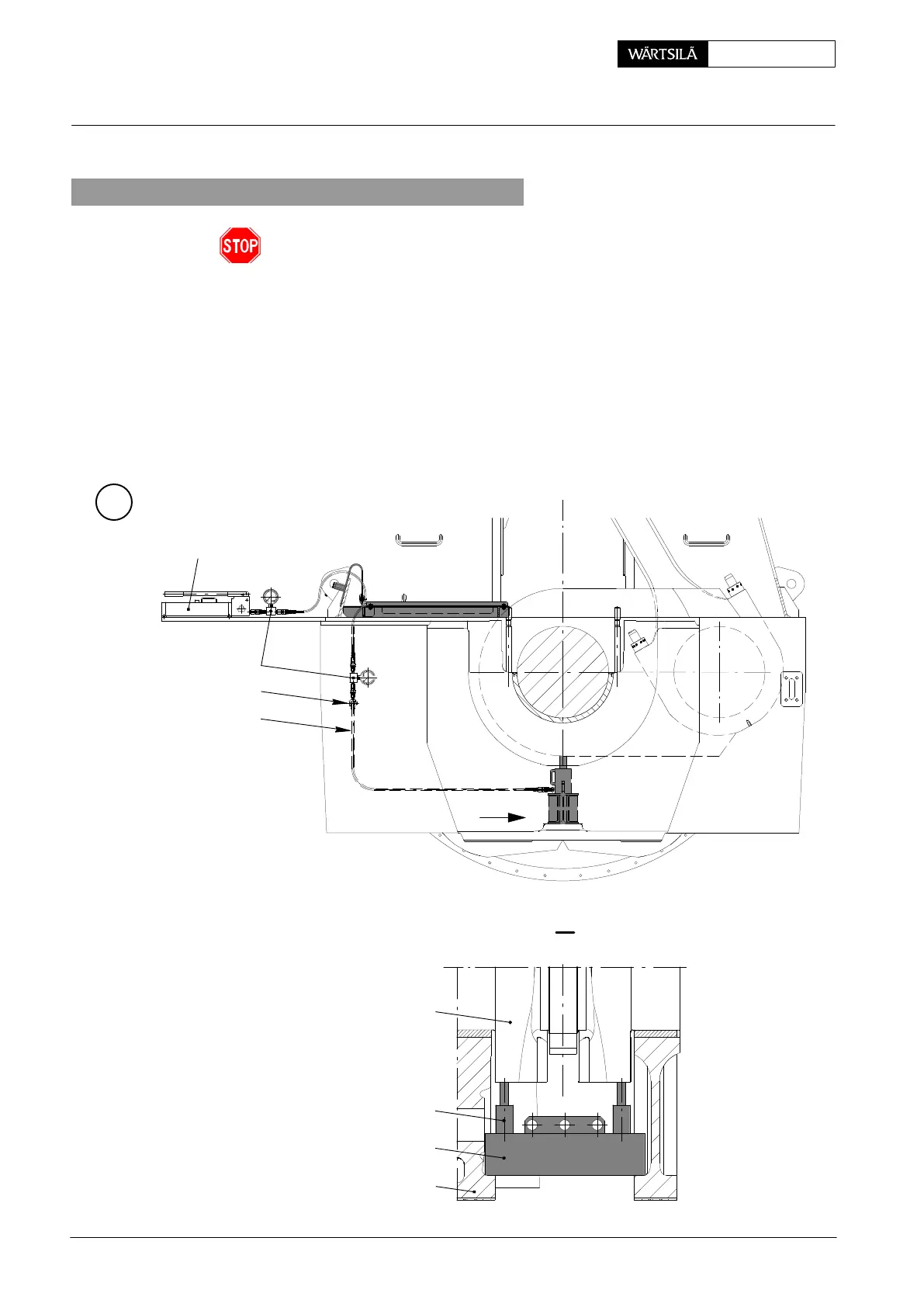

⇒ Turn corresponding crank to exhaust side approx. 90_ after T.D.C.

⇒ Put support 94141 on two main bearing girders 2 parallel to the engine axis.

⇒ Place hydraulic jacks 94936 on support 94141 and connect them with HP oil

pump 94931.

G

013.213/05

013.214/05

I

I

94934a

94931

94934

94935

94936

1

2

94141

2010

Removal and Fitting of a Main Bearing

Loading...

Loading...