Maintenance3403−1/A1 RT-flex50-D

Wärtsilä Switzerland Ltd

8/ 8

5.1 Fitting

⇒ Turn crank of the cylinder concerned to T.D.C.

⇒ Slightly lift piston by crane. Loosen screwed con

nections 14 (Fig. ’F’) and push both supports 1

outwards. Then lift the piston including piston ro

gland 12 so far that the two hinged covers 11 ca

be turned up.

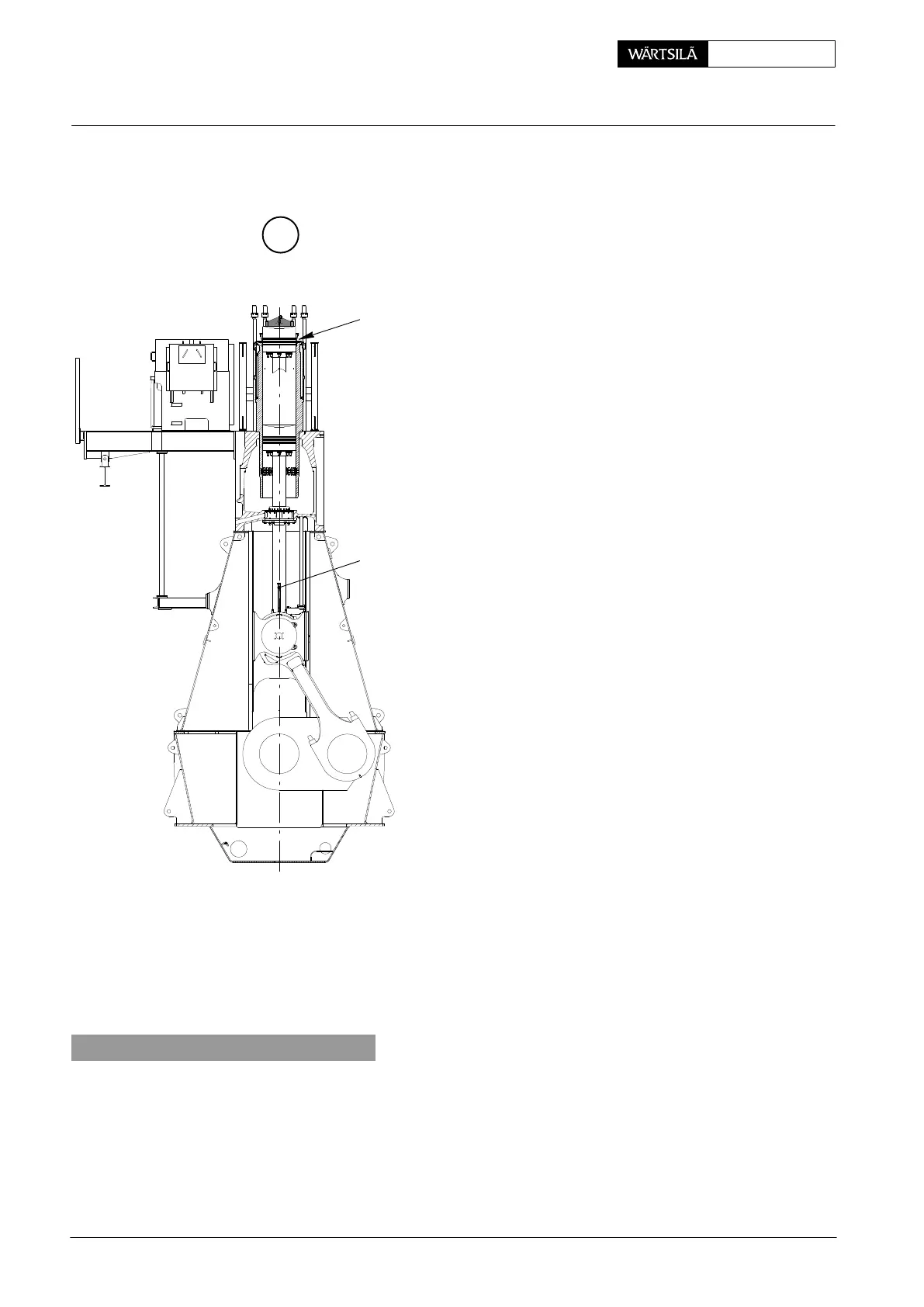

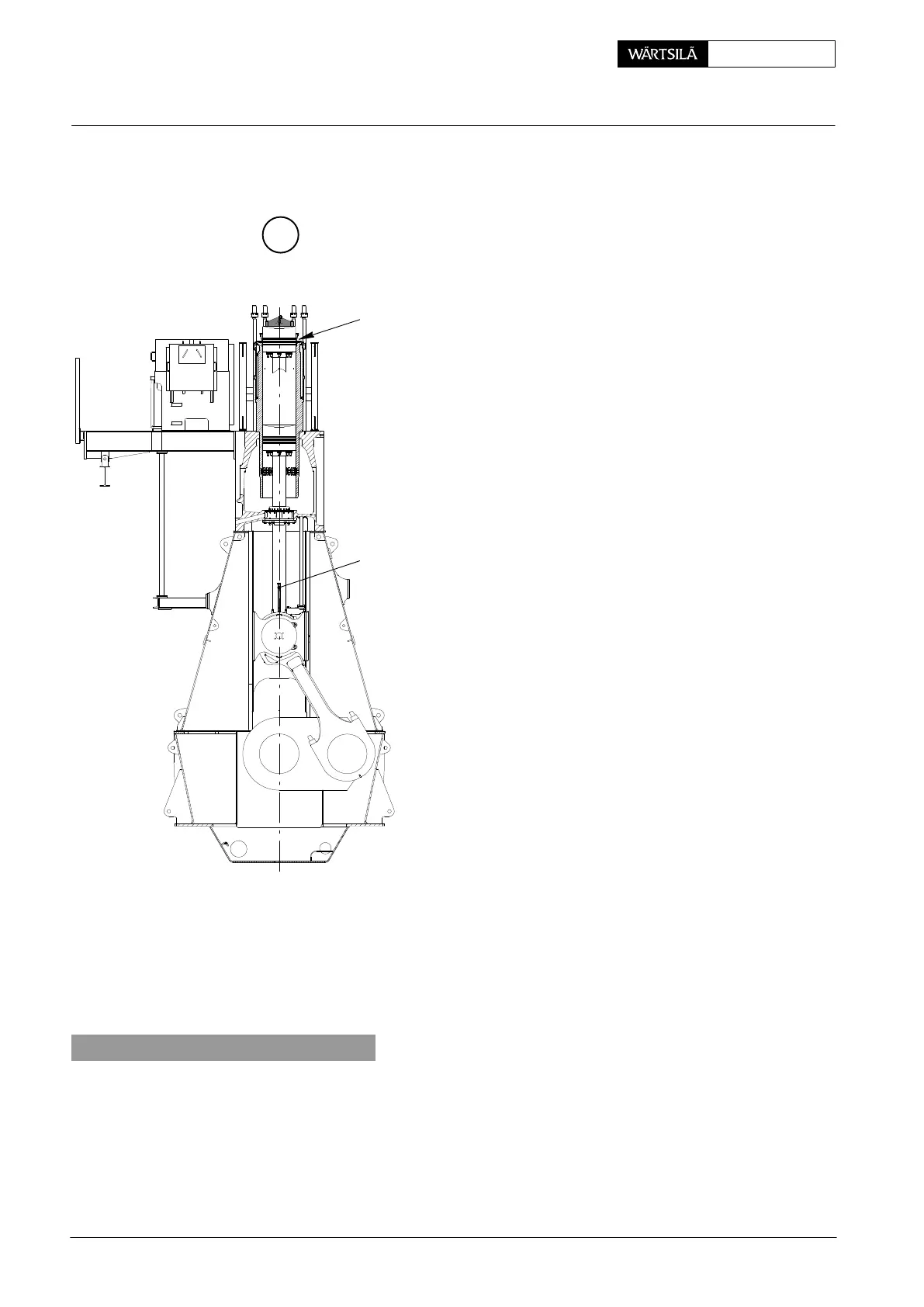

⇒ Bring the piston over the cylinder liner and the

slowly lower it (Fig. ’I’).

D When the piston is lowered into the cylinder line

until the lowest piston ring is at the upper level o

the insertion funnel, arrange the piston rings s

that their gaps alternate by 180_ to each other (se

3425−1).

⇒ Slowly lower the piston further till its piston rod foo

has arrived just above the crosshead pin. Whil

one person directs the further lowering of the pis

ton from the top, another directs the piston ro

progress from the engine interior and how it mus

be turned to guide the piston rod foot, without jam

ming, into centring pins 6 (Fig. ’A’) in the crosshea

pin.

⇒ Slacken the crane rope a bit and remove the sus

pension device.

⇒ Turn piston to B.D.C. (loosen crane correspond

ingly) and direct the insertion of the piston ro

gland into its seating bore in the cylinder block (se

2303−1).

⇒ Loosen and remove both distance holders from

the piston foot.

⇒ Firmly tighten all screws fastening the piston ro

gland housing.

⇒ Tension waisted studs 3 for the piston foot fasten

ing as described in section 3.

⇒ Refit the antipolishing ring (see 2124−2).

I

018.391/09

94342

94345

6. Leak test

A leak test must be carried out after every fitting of a piston in the cylinder. For this,

start the bearing lubrication pump and set the bearing lubricating pressure. Check

through the scavenge space on the fuel side in the cylinder block (piston under-

side) whether cylinder liner running surface and piston rod remain dry.

Any increase in the dirty oil level in the scavenge air space may be caused by a

faulty O-ring in the piston.

2010 / 50−D

Piston: Removal and Fitting

Loading...

Loading...