Maintenance

3303−2/A1

RT-flex50-D

Wärtsilä Switzerland Ltd

1/ 4

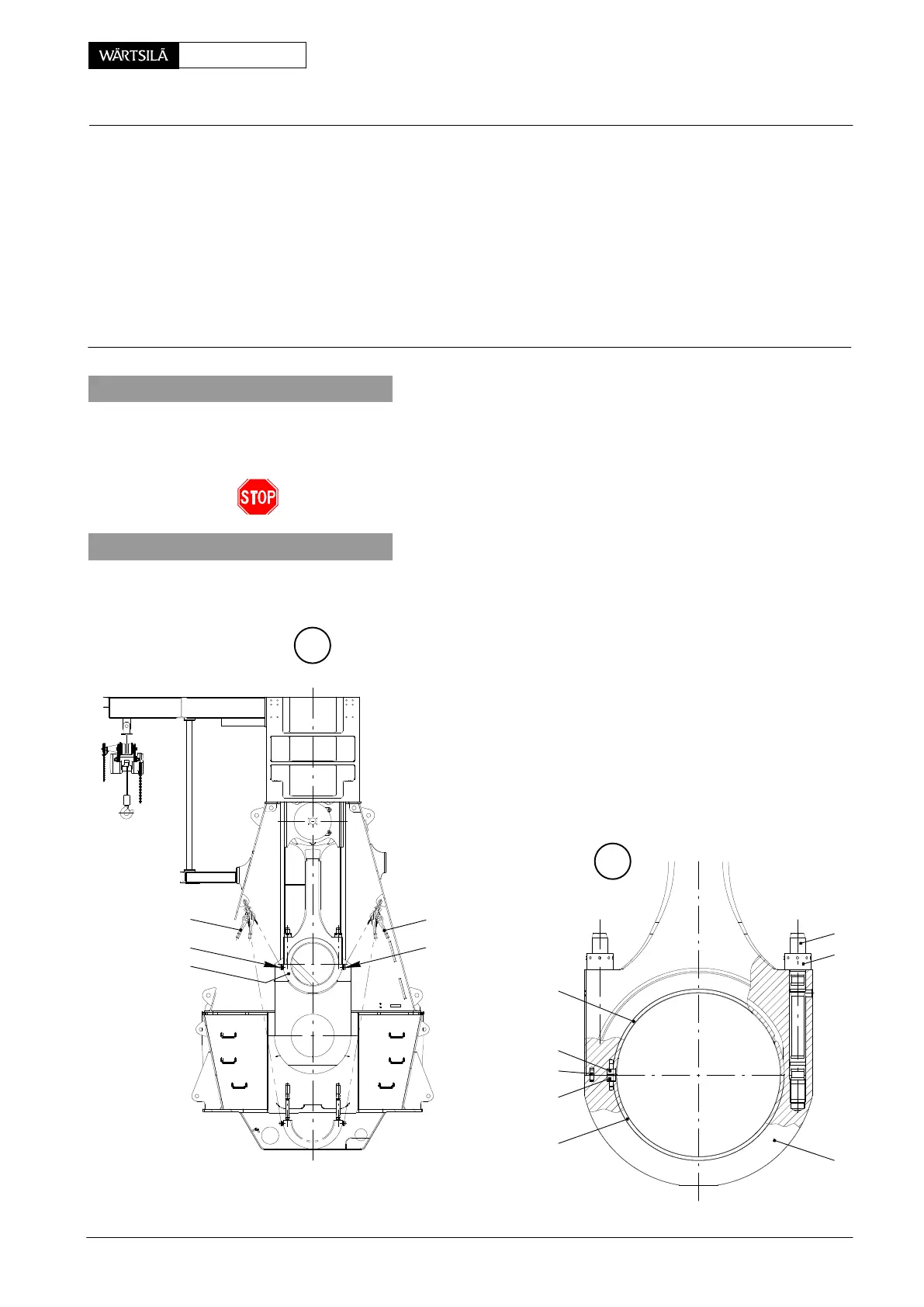

Tools: Key to Illustrations:

1 Working platform 94142 1 Connecting rod stud 9 Cylindrical pin

4 Retaining pins 94323 2 Nut 10 Upper bearing shell

3 Crank 11 Spur-geared chain block

4 Bearing cover

5 Connecting rod

6 Guide way HZ Lifting tackle

7 Lower bearing shell RC RUD-eye bolt M16

8 Allen screw RC

1

RUD-eye bolt M8

1. General

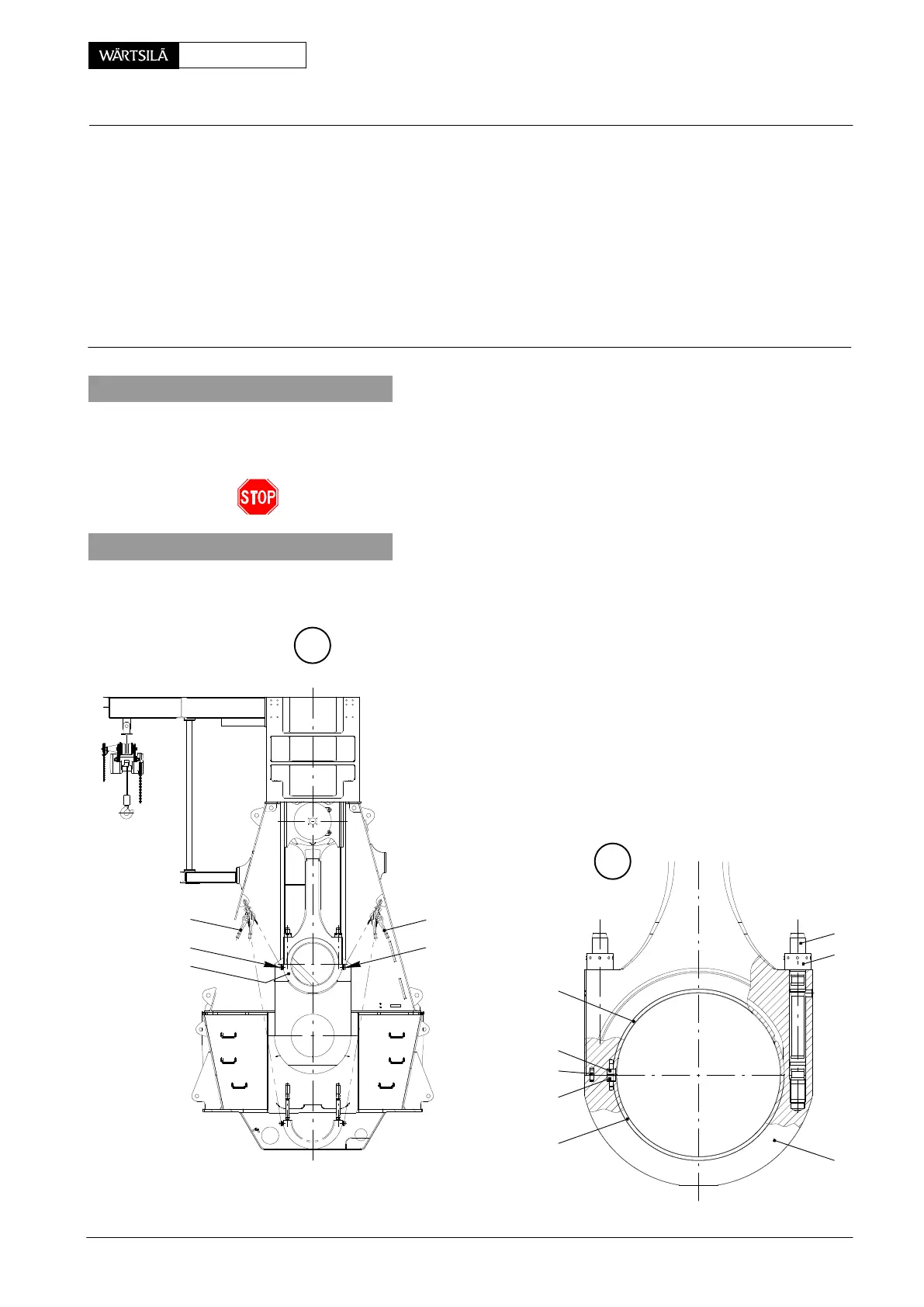

When a bottom end bearing has to be inspected or removed, nuts 2 of connecting

rod studs 1 (Fig. ’B’) have to be loosened according to the instructions in 3303−1,

for which the respective crank must be at T.D.C.

Never turn the crankshaft as long as the pre-tensioning jacks are screwed onto the

connecting rod studs.

2. Inspection and removal

2.1 Lowering the bearing cover

⇒ Fit a RUD-eye bolt ’RC’ on each side of bea

ing cover 4 directly below the bearing separ

tion.

⇒ Attach lifting tackle as shown in Fig. ’A’, co

nect ropes ’a’ and ’b’ with lifting tackle ’H

and RUD-eye bolts ’RC’. Tighten the ropes

⇒ Remove nuts 2.

⇒ Carefully lower the bearing cover 4 while ta

ing care that the threads of the connectin

rod studs as well as the surface of the cran

pin are not damaged.

A

B

10

8

9

8

7

HZ

RC

HZ

RC

4

013.502/05

013.503/05

ab

onnecting Rod

nspection, Removal and Fitting of Bottom End Bearing

2010

Loading...

Loading...