Maintenance

1715−1/A1

RT-flex50-D

Wärtsilä Switzerland Ltd

1/ 2

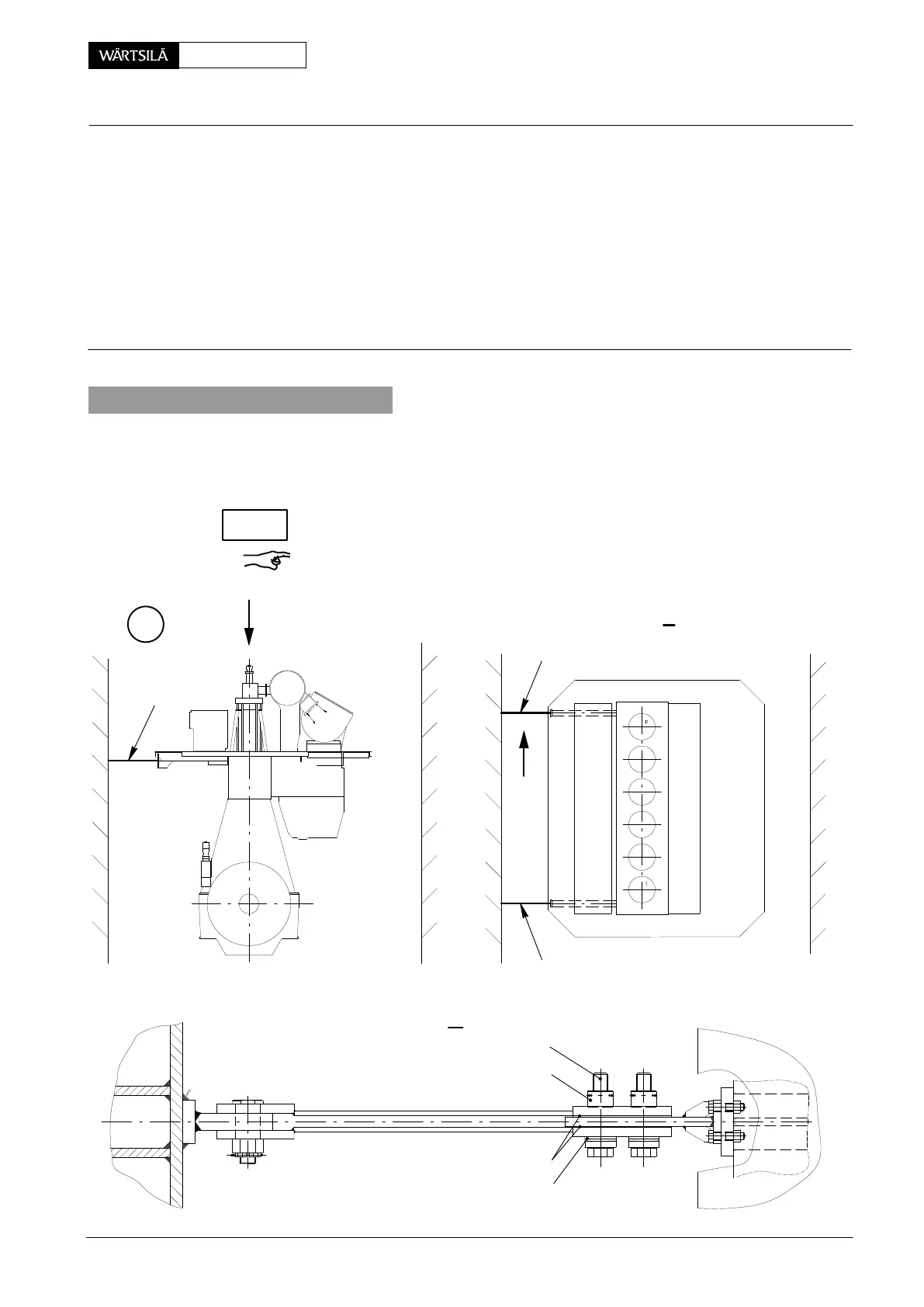

Tools: Key to Illustrations:

1 Feeler gauge 94122 1 Engine stays

1 Pre-tensioning jack 94145 2 Friction shims

1 HP oil pump 94931 3 Screw

2 Hydr. distributors 94934a 4 Nut

1 HP hose 94935 5 Disc spring BN Limiting groove

6 Vent screw EV Relief valve

7 Piston KO Slot

8 Cylinder RS Round bar

1. General

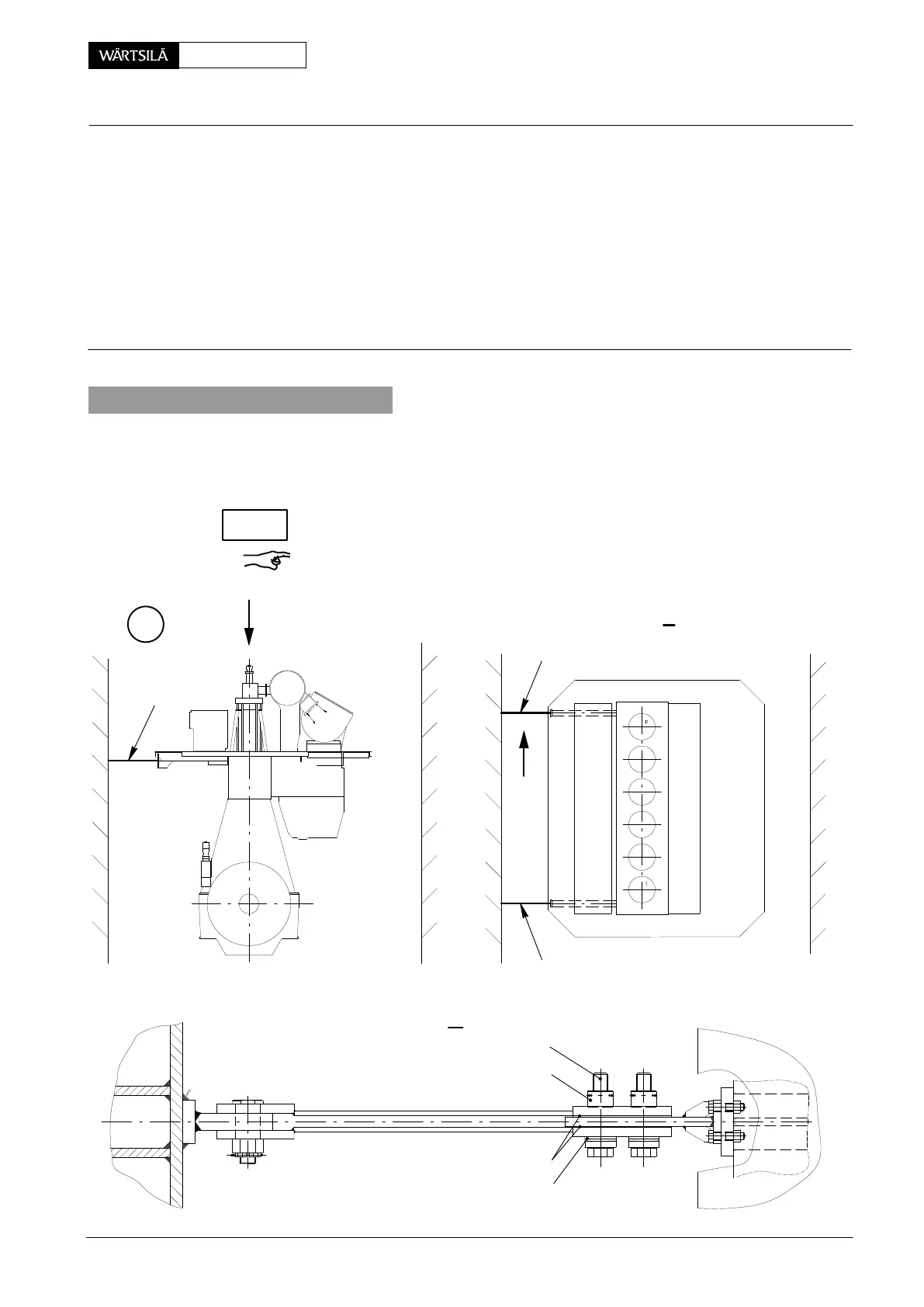

Two friction type stays 1 each are installed either on exhaust side or on fuel side as

shown in Fig. ’A’.

The pre-tension of screws 3 must be checked at specified intervals (see 0380−1).

Remark: Pay attention to General Application Instructions 9403−4 for hydraulic

pre-tensioning jacks.

II

1

1

1

FREE END

I

I

II

2

5

4

A

3

012.996/05

ngine Stays with Friction Shims

hecking the Pre-tension

2010

CHECK

Loading...

Loading...