Maintenance

3403−3/A1

RT-flex50-D

Wärtsilä Switzerland Ltd

3/ 6

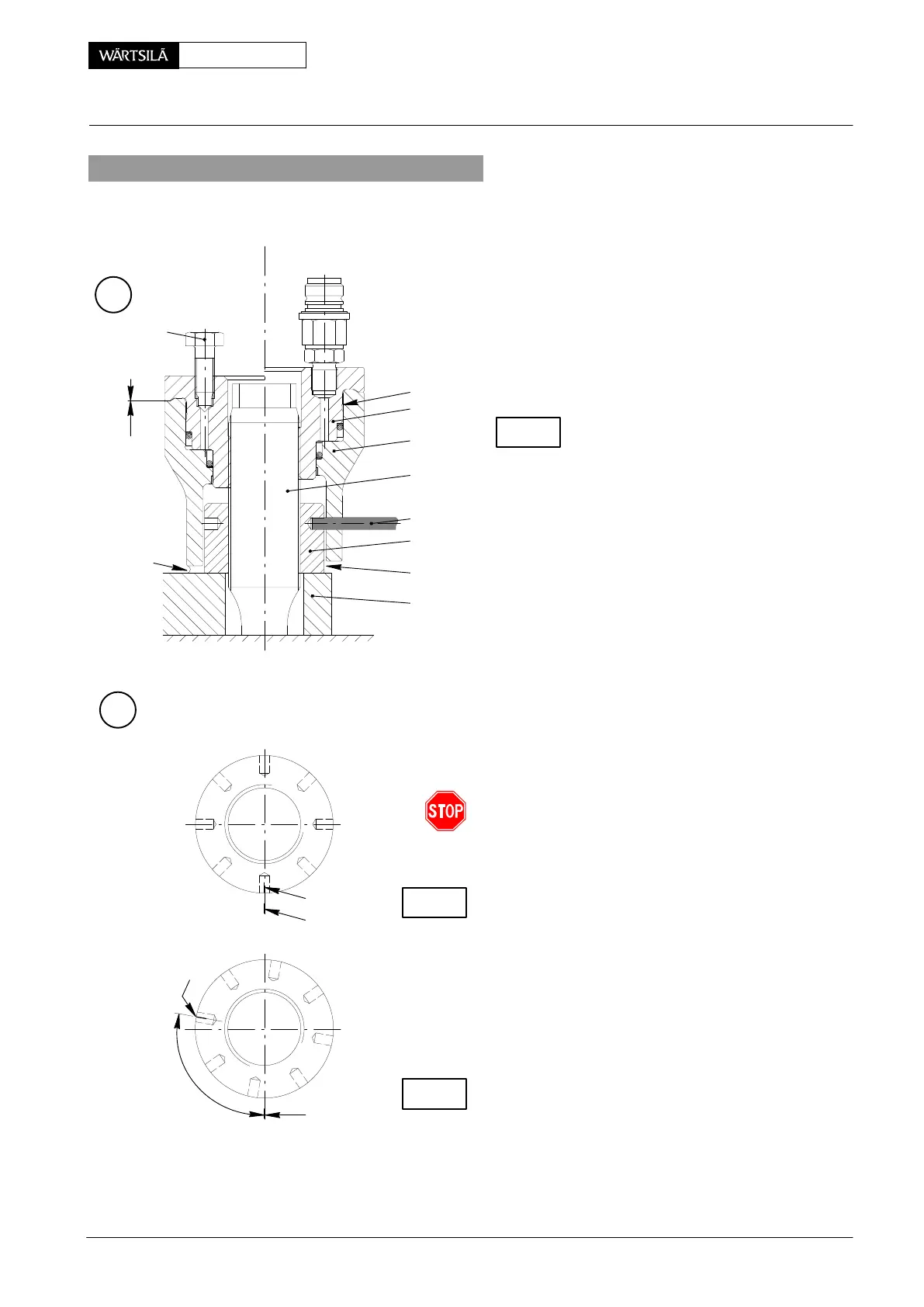

3. Tensioning waisted studs of piston crown

⇒ Clean the threads of waisted studs

and the area around nuts 13.

⇒ Apply oil to the threads of waiste

studs and screw on the nuts.

⇒ Tighten the nuts with round bar ’R

by hand.

Using a feeler gauge, check whether th

nuts rest without clearance.

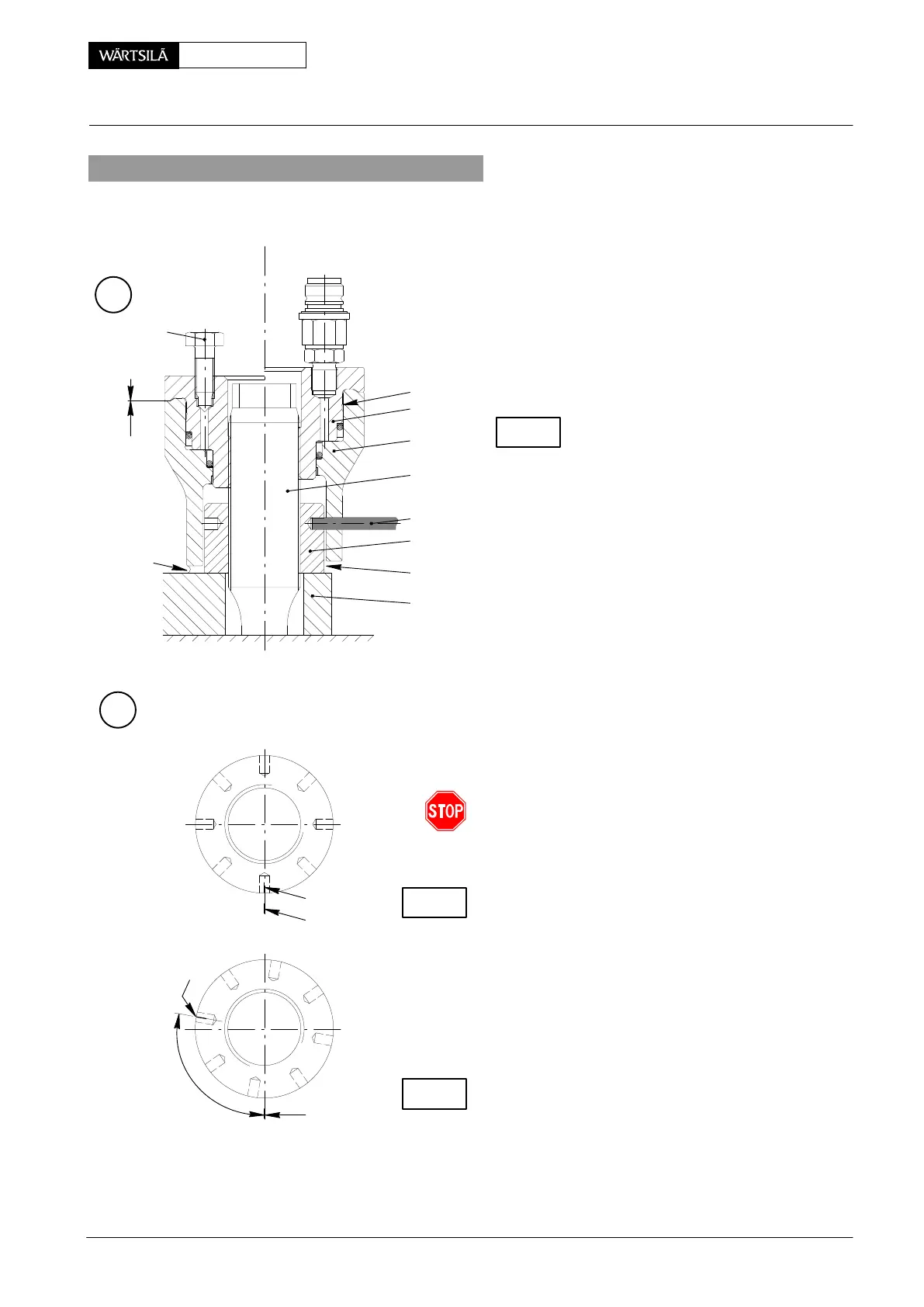

⇒ Mark position of nuts to seating su

face with a felt tipped pen (Fig. ’a’)

⇒ Place pre-tensioning jacks 9434

crosswise on the waisted studs a

shown in Fig. ’A’, and complete

screw them on with opened ve

screws 16 till there is no or little clea

ance at ’x’.

⇒ Connect the pre-tensioning jacks

the hydraulic unit 94942.

⇒ Start up hydraulic unit.

⇒ Close vent screws 16 as soon as oil flows o

bubble-free.

⇒ Operate the hydraulic unit till a pressure of 1500 ba

is reached.

Pistons 14 of the pre-tensioning jacks must never e

ceed the red limiting grooves ’BN’ (Fig. ’B’).

⇒ Keep the pressure of 1500 bar constant and tighte

nuts 13 with round bar ’RS’ till firmly seated.

After tensioning the nuts check their seatings with

feeler gauge through slot ’KO’.

⇒ Always the same procedure is to be applied cros

wise according to the sequence for tensioning th

remaining waisted studs.

⇒ Remove pre-tensioning jacks.

After tensioning the nuts check if these have bee

turned by about the same angle, i.e. approx. 115_

compared with the marks previously made (Fig. ’b’).

CHECK

CHECK

PRE-TENSIONING JACK PLACED FOR

TENSIONING

LOOSENING

x

Fig. ’a’

Fig. ’b’

y

x

011.675/04

y

TIGHTENING

ANGLE

CHECK

B

015.888/07

C

SA

x

16

5

13

RS

14

BN

15

KO

4

2010

Piston: Removal and Fitting

Loading...

Loading...