Maintenance

2751−2/A1

RT-flex50-D

Wärtsilä Switzerland Ltd

1/ 9

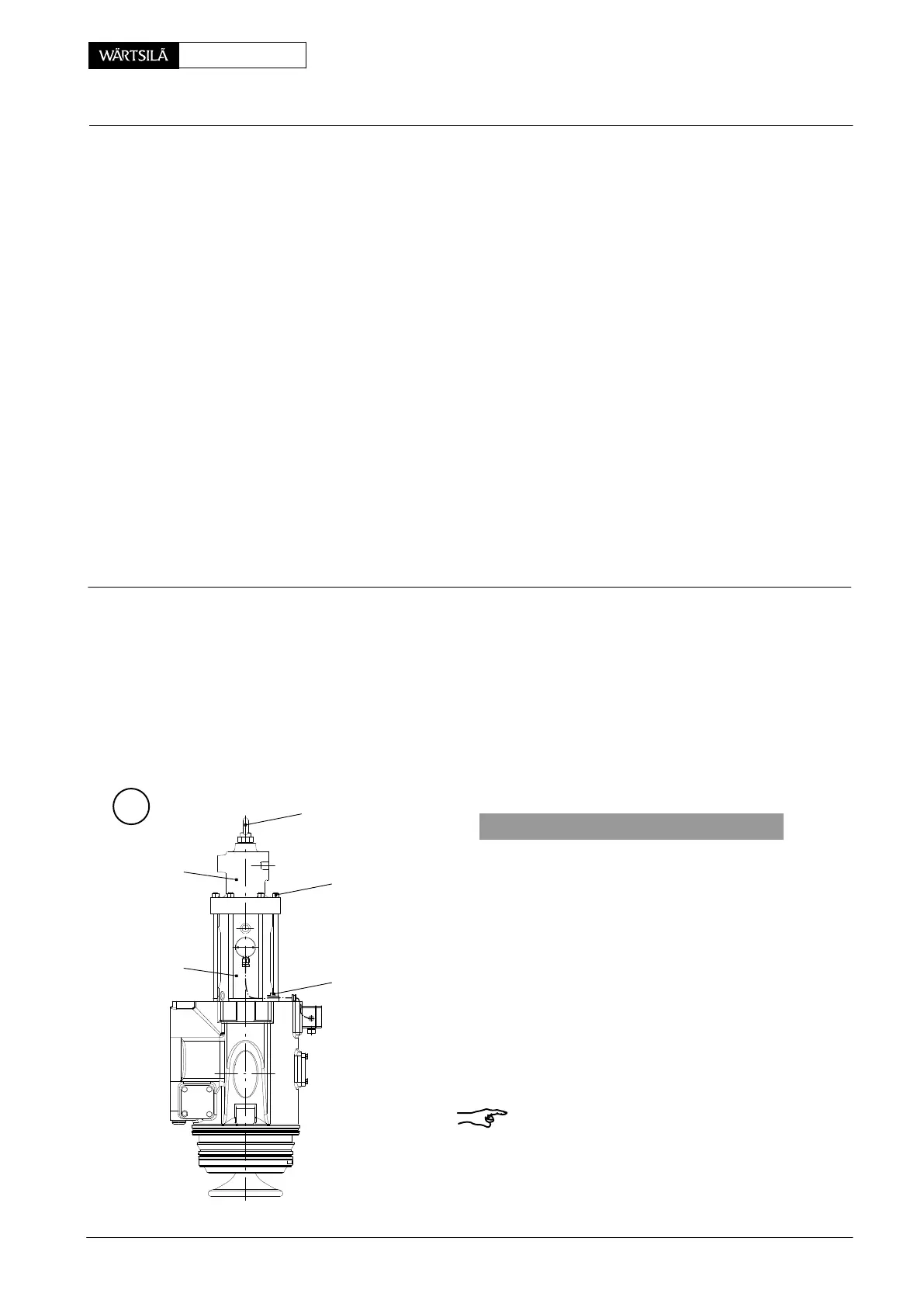

Tools: Key to Illustrations:

1 Depth gauge 94126 1 Valve cage 21 Guide bush

1 Pressure element 94259a 2 Lower housing 22 Rod seal ring

1 Torque wrench 3 Nut 23 Valve seat

4 Screw 24 Screw plug

5 Upper housing 25 Filter with orifice

6 Outside piston 26 Adapter

7 Inside piston 27 Non-return valve

8 Thrust piece 28 Throttle screw

9 Valve spindle 29 Spring dowel pin

10 Measuring cone 30 Valve stroke sensor

11 Piston guide 31 Screw

12 Spring dowel pin 32 Housing

13 Screw with washer 33 Damper

14 Circlip 34 Shim

15 Valve cotter 35−42 O-rings

16 Piston

17 Piston seal ring BO Bore

18 Disc spring HH Hydr. HP pipe

19 Distance ring OB Oil bore

20 Head screw RC Eye bolt

Overview

1. General 1/9...............................................

2 Dismantling of exhaust valve 3/9...........................

3. Assembling of exhaust valve 5/9...........................

4. Blocking of exhaust valve 9/9..............................

A

1. General

There are in minimum two complete exhau

valves on board, as recommended by the Intern

tional Association of Classification Societie

(IACS). Therefore, they must be used as a r

placement in any case of difficulties appeare

during operation.

Defective exhaust valves may, however, only b

repaired or reconditioned by qualified personn

or a Wärtsilä Switzerland Ltd. authorized repa

workshop.

For inspection and overhaul intervals see Maint

nance Schedule 0380−1.

Remark: Pay attention to General Guidelines f

Lifting Tools 0012−1.

RC

3

013.145/05

4

2

5

xhaust Valve

ismantling and Assembling

2011-12

Loading...

Loading...