Maintenance

9223−1/A1

RT-flex50-D

Wärtsilä Switzerland Ltd

21/ 22

9.5 Checking the clearance between shaft and internal bearing of the CAS

In case the CAS is over five years in service or has more than 48 000 operating

hours, it is recommended to check the condition of the CAS before a new belt ver-

sion is installed. The CAS condition is checked by measuring the clearance be-

tween the shaft and internal CAS bearing.

Procedure for measuring the clearance:

⇒ Remove the protection hood 1 of the CAS drive (see Fig.’B’).

⇒ Remove the protection plate 10.

⇒ After loosening the screws 15a and 15, remove first the toothed belt of the out-

er CAS and then the toothed belt of the inner CAS.

⇒ After removing the toothed belt, tighten the screws 15a and 15 again.

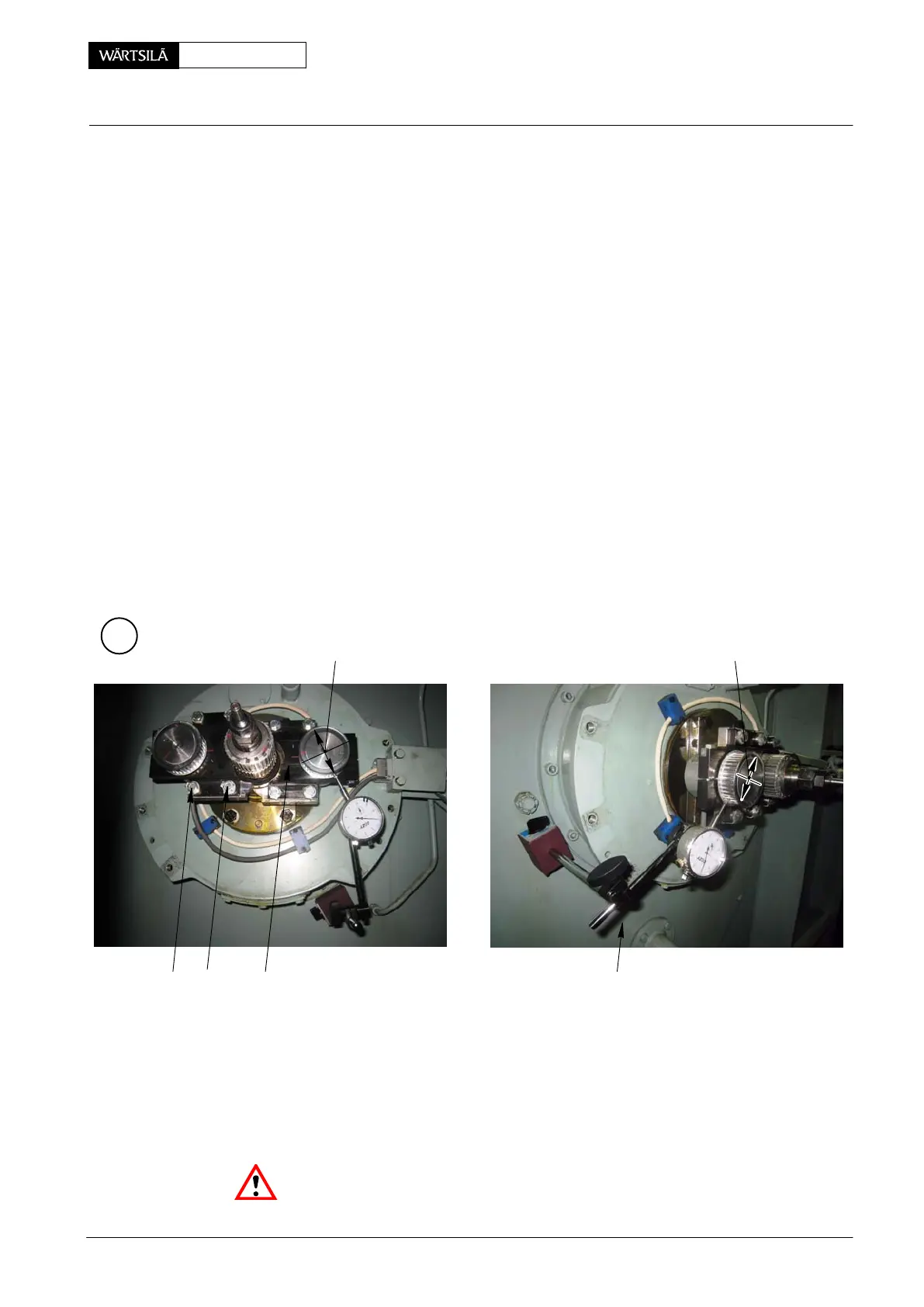

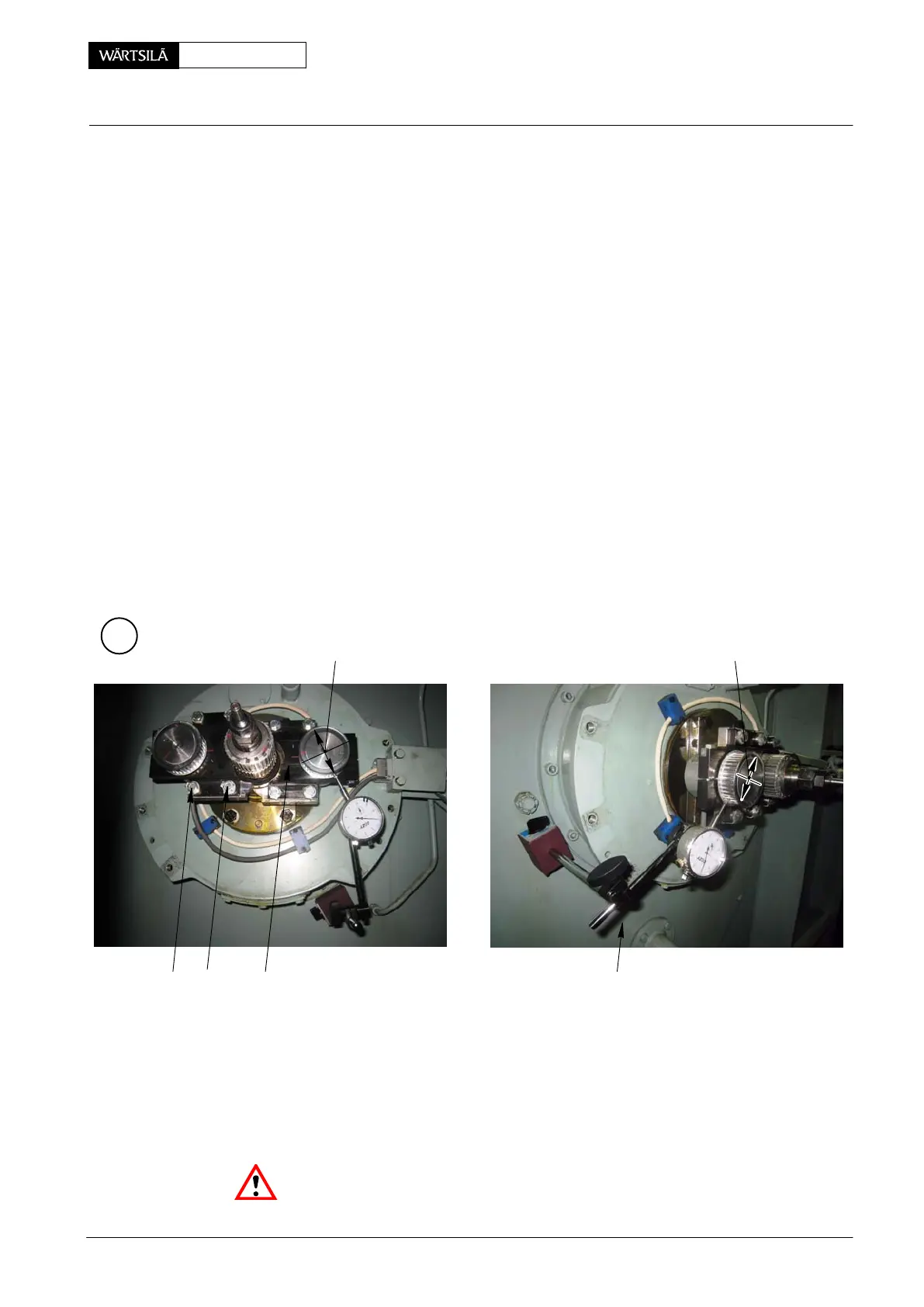

⇒ Install the magnetic base with dial gauge ’MB’ as shown below.

⇒ Push the gear wheel of the CAS to the left and right direction.

The measurements ’X’ and ’Y’ have to be done in fixed condition of the outer and

inner CAS but without the toothed belts.

⇒ Read the deviation on the dial gauge while pushing the gear wheel of the CAS.

The average CAS clearance under normal working and in assembly condi-

tion must be less than 0.05 mm.

MB1015a 15

XY

E

1

9.6 Checking the toothed belt condition

The toothed belt has to be checked every 3000 operating hours for its pre-tension.

In addition a visual inspection of the belt ha to be performed, which means check-

ing for possible cracks and worn-out areas.

Attention! Worn-out toothed belts must be replaced immediately.

2012

rank Angle Sensor Unit: Dismantling, Assembling and Adjusting

Loading...

Loading...