Maintenance

2745−1/A1

RT-flex50-D

Wärtsilä Switzerland Ltd

1/ 2

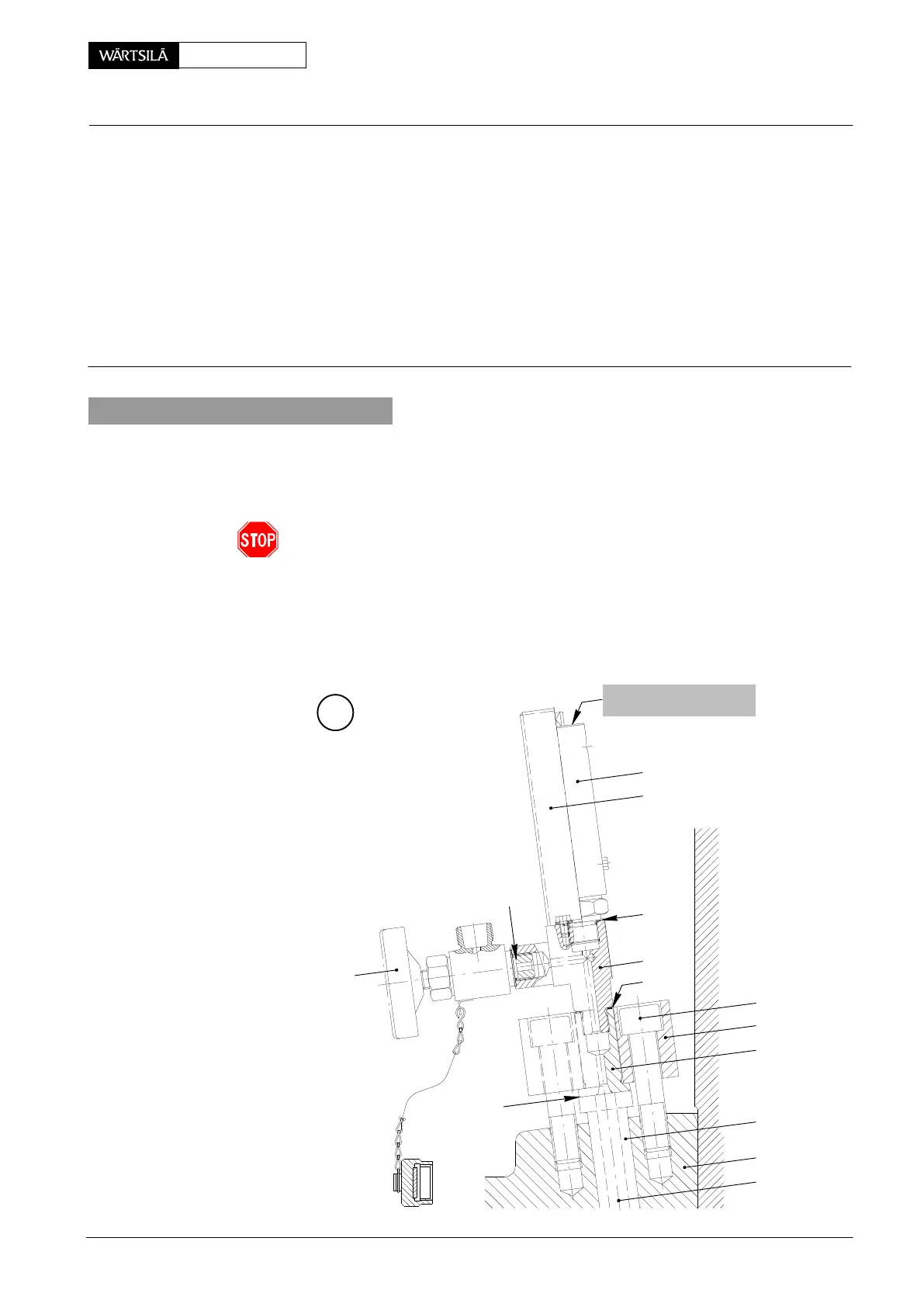

Tools: Key to Illustrations:

1 OBEL test bench 94272 1 Cylinder cover 10 Receiver

1 Valve holder 94272c 2 Relief valve 11 Gasket

1 HP oil pump 94931 3 Indicator valve 12 Gasket

2 Hydr. distributors 94934a 4 Adapter piece

1 HP hose 94935 5 Protection plate

6 Flange EV Relief valve

7 Adapter MD Metallic sealing

8 Sleeve RB Relief bore from

9 Allen screw compression chamber

1. General

Each cylinder cover is provided with an indicator valve combined, depending on

Class requirements, with a relief valve, which is connected by relief bore ’RB’ to the

compression chamber. An inadmissible high pressure peak in the compression

chamber opens the valve and the over-pressure is immediately reduced.

A relief valve which has blown off or valves leaking during engine operation

must be replaced at the first opportunity (with engine stopped only).

A relief valve can not be repaired nor adjusted any more after having blown-

off!

Relief valves require no maintenance, however they should be checked in general

at every major engine overhaul. Basically leaking or damaged valves should be

returned to the manufacturer for inspection and repair.

A

017.671/08

2

3

5

11

4

12

12

MD

BLOW-OFF PRESSURE

STAMPED IN

9

6

7

8

1

RB

elief Valve for Cylinder Cover

hecking Blow-off Pressure

2010

Loading...

Loading...