Maintenance

8447−1/A1

RT-flex50-D

Wärtsilä Switzerland Ltd

1/ 4

Tools: Key to Illustrations:

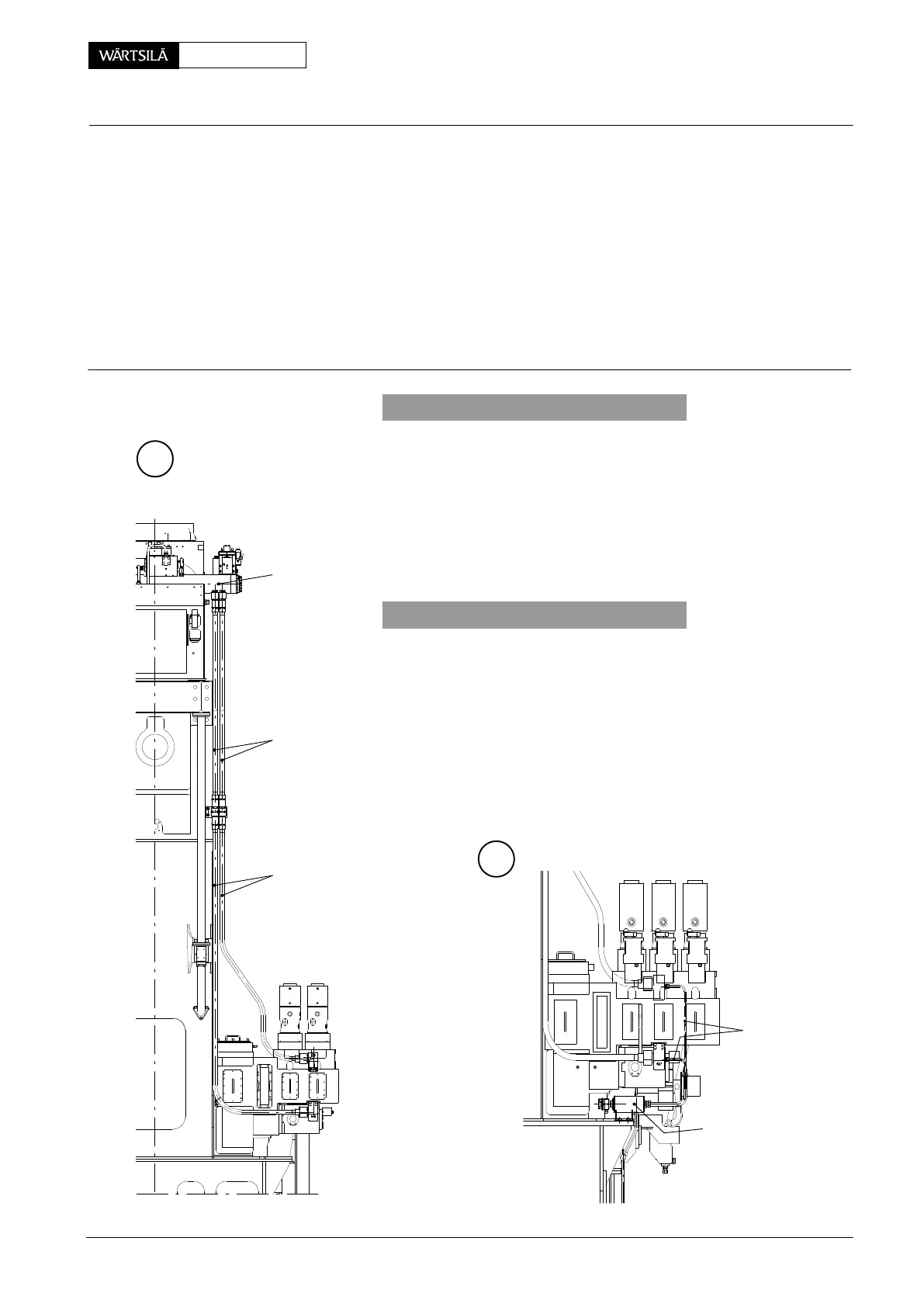

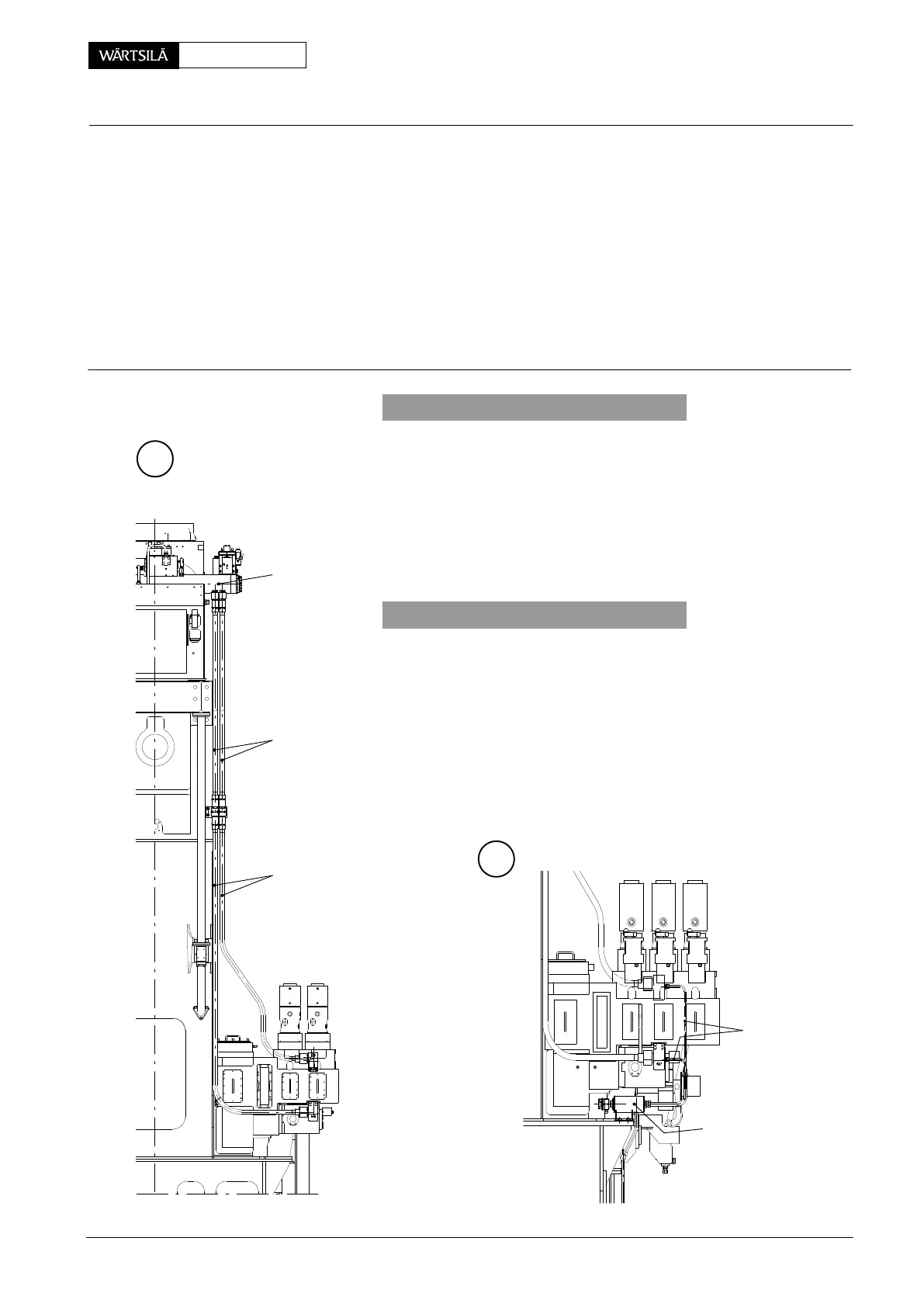

1 Regrinding device 94834 1 Servo oil rail 10 Thrust ring

2 Servo oil piping 11 Non-return valve

3 Servo oil piping 12 Leakage oil pipe

4,a,b Screw 13 Oil leakage monitoring

5,a Flange 14 Connecting block

6 Screw 15−17 O-ring

7 Intermediate piece

8 Non-return valve DF Sealing face

9 Claw OE Oil inlet

A

1

2

013.511/05

1. General

The engine must be stopped and then the servo oil pipings ca

be drained via leakage oil pipes 12, however, also a tray shou

be placed under the connecting blocks.

D For that screws 4a must be loosened and flange 5a, resp.

and 5 at connecting block 14 pushed back in order to sep

rate servo oil piping from its sealing faces ’DF’.

Non-return valves 11 prevents servo oil rail from discharging

2. Removal

D Depending on the servo oil piping to be removed, the pi

ing from servo oil service pump 4.88 to oil inlet ’OE’ (Fi

’C’) must also be removed.

D To remove servo oil piping 2, the relevant servo oil piping

must be removed first.

D Pay attention not to damage sealing faces ’DF’.

D All connections must be closed off immediately and th

sealing faces must be protected against any damages.

12

13

B

3

ervo Oil Piping

emoving, Fitting and Regrinding

2010

Loading...

Loading...