Maintenance

2708−2/A1

RT-flex50-D

Wärtsilä Switzerland Ltd

3/ 3

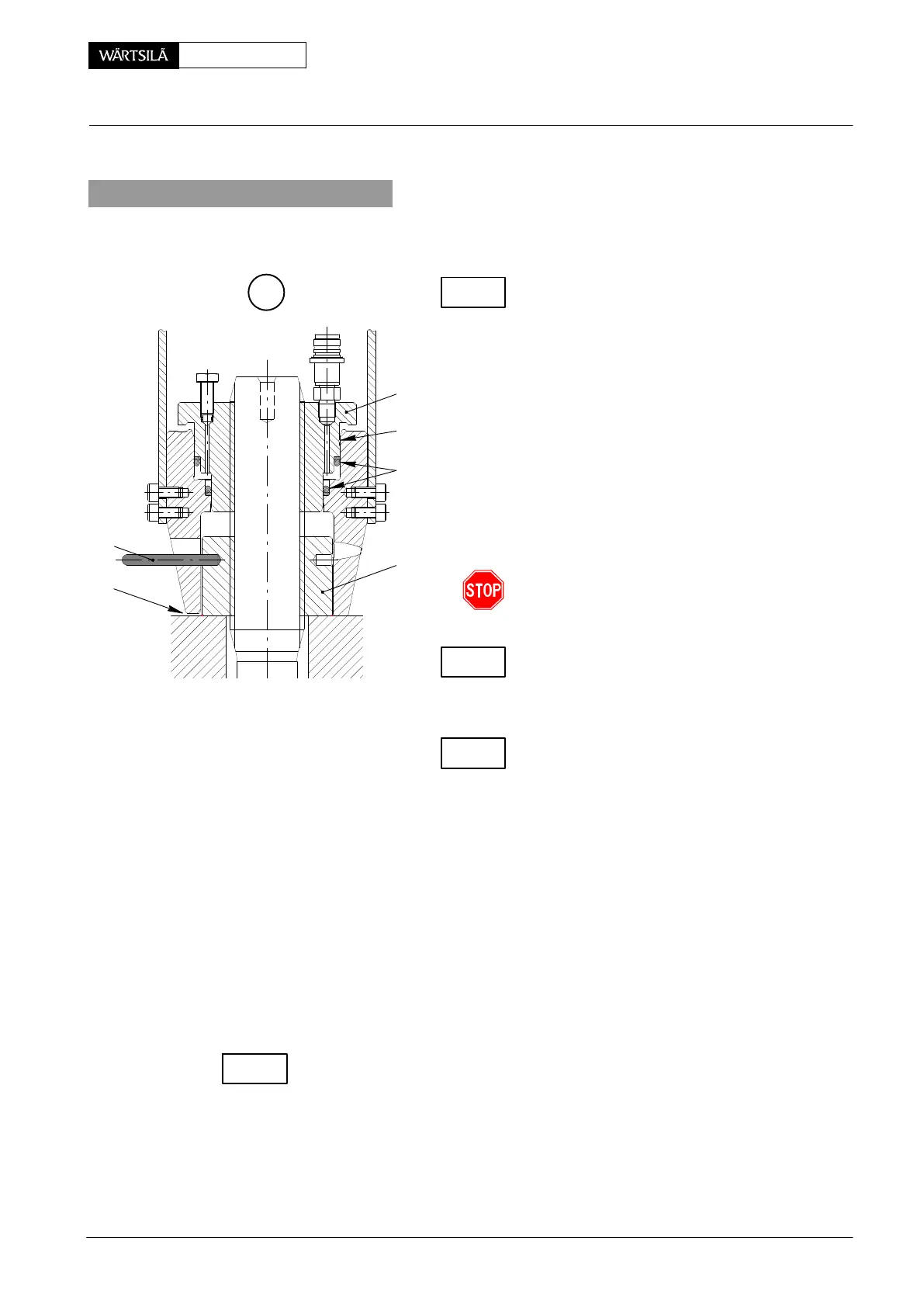

4. Tensioning

Using a feeler gauge, check whether nuts 2 re

without clearance.

⇒ Mark position of nuts to seating surface with

felt tipped pen.

⇒ Screw pre-tensioning jacks 94252 onto cyli

der cover studs 1 as mentioned in section

however, do not turn back them.

⇒ Connect pre-tensioning jacks to hydraul

unit 94942 and actuate the latter.

⇒ Close vent screws 3 on the pre-tensionin

jacks as soon as oil flows bubble-free.

⇒ Slowly raise the pressure to 1500 bar an

keep it constant.

Pistons 4 of the pre-tensioning jacks must neve

exceed the red limiting grooves ’BN’.

⇒ Tighten nuts 2 with round bar ’RS’.

Check seating of the nuts with a feeler gaug

through slot ’KO’.

⇒ Release pressure to ’0’ and remove all pr

tensioning jacks.

Ascertain that these have been turned by abou

the same angle of 255_.

CHECK

CHECK

CHECK

C

S

O

012.964/05

4

BN

7

2

D Where it is found that a nut can be turned considerably less than the others, it

must be assumed that the respective cylinder cover stud has become insuffi-

ciently tensioned.

Possible causes:

− Sealing rings 7 defective (Fig. ’C’).

− Piston 4 jams.

− Junctions of HP hoses leaky.

D To remedy the cause, loosen all cylinder cover studs and then repeat the ten-

sioning procedure.

⇒ Release pressure to ’0’ and remove all pre-tensioning jacks.

Verify that all nuts have been turned equally by an angle of about 255_.

Loosening and Tensioning of Cylinder Cover Waisted Studs

2010

CHECK

Loading...

Loading...