Maintenance

9223−1/A1

RT-flex50-D

Wärtsilä Switzerland Ltd

9/ 22

5. Dismantling the crank angle sensor drive

Recommendation: To ensure a high availability and quality standard we recom-

mend that a complete crank angle sensor drive according to Fig. ’K’, view II (in-

cluding shaft encoder Fig. ’D’) always be kept in stock. Maintenance works as de-

scribed in sections 5 and 6 may be carried out only by qualified manufacturers as a

matter of principle.

⇒ Remove shaft encoder according to paragraphs 1.2 and 1.3.

⇒ Unbend locking plate 24, loosen and remove shaft nut 25 using hook spanner

94924.

⇒ Withdraw gear wheel 18 from the shaft 5.

Remark: If withdrawing by hand is not possible, the gear wheel must be removed

by means of the two tap holes ’GL’ and suitable tools, however, without striking and

damaging the toothing.

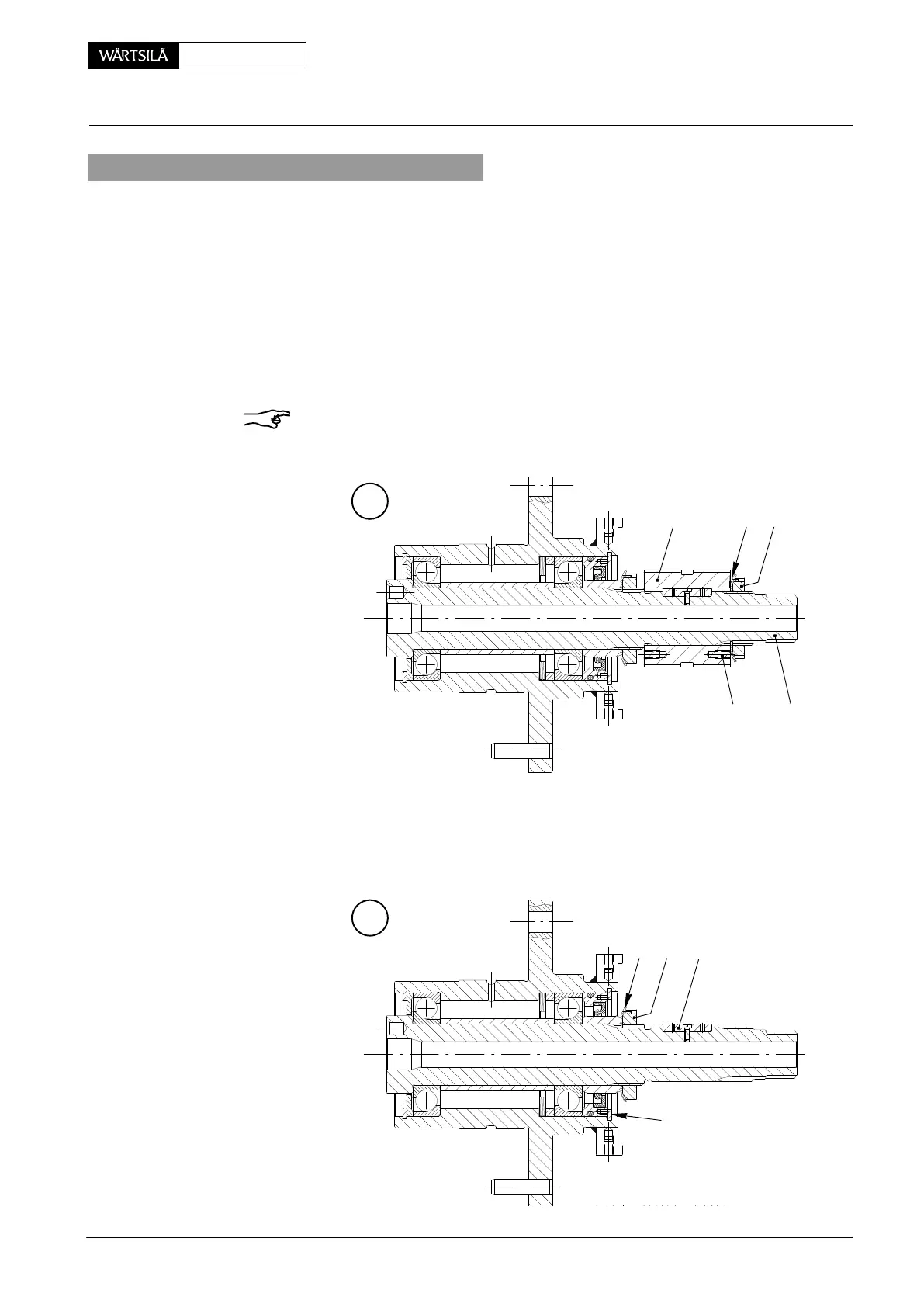

L

18 2524

5

GL

⇒ Remove circlip 28 using a snap ring tong.

⇒ Unbend locking plate 26, loosen and remove shaft nut 27 using hook spanner

94925.

⇒ Remove shaft 5, however, key 38 remains in situ.

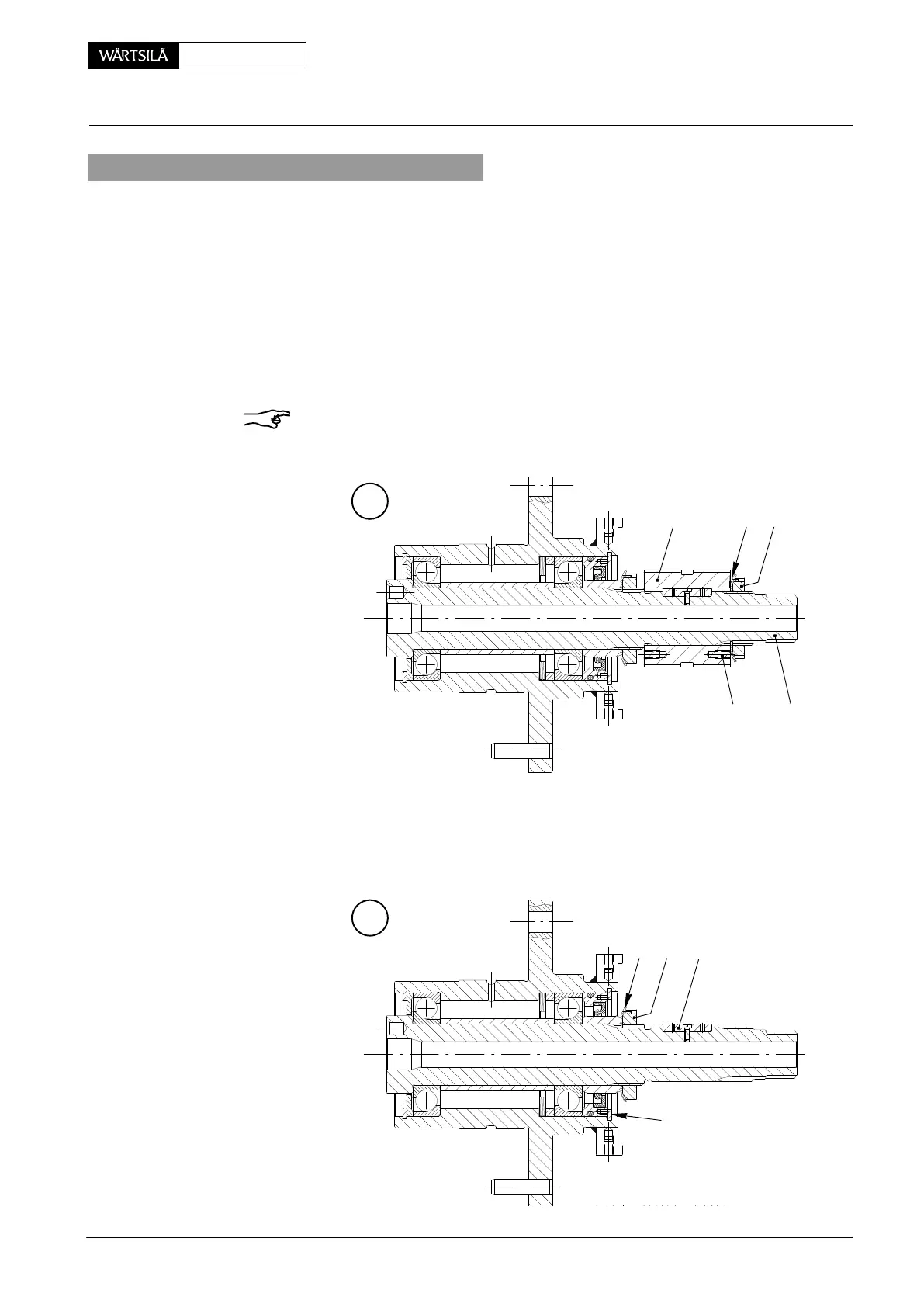

M

38

28

27

26

2011

rank Angle Sensor Unit: Dismantling, Assembling and Adjusting

Loading...

Loading...