Maintenance4103−1/A1 RT-flex50-D

Wärtsilä Switzerland Ltd

2/ 2

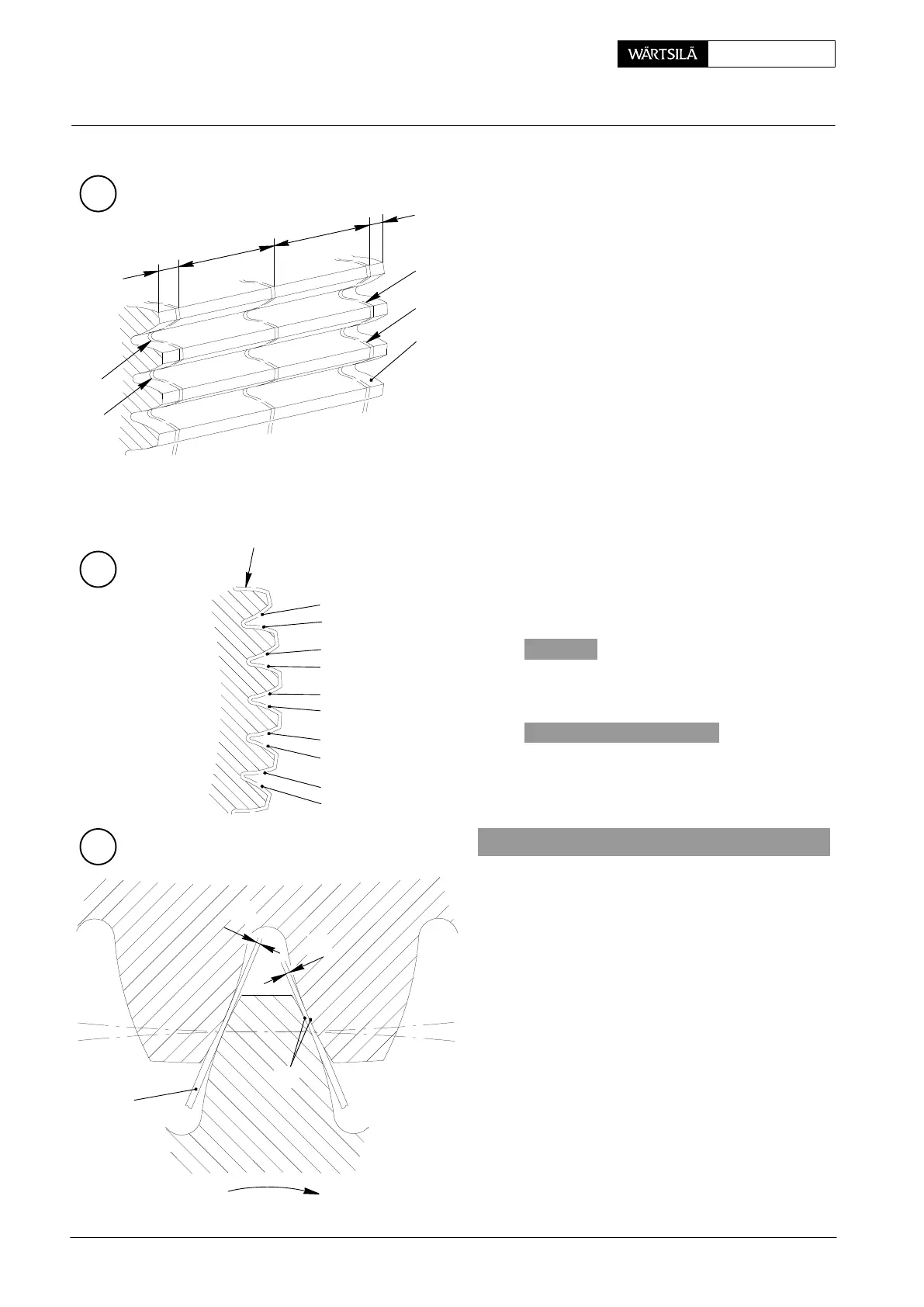

3.3 Measuring tooth backlash with lead wire

D Use a fresh piece of lead wire Pb 99.9 fine

1.5 mm diameter for each measurement.

D Always use lead wires of the same diamet

and quality.

⇒ Place lead wire pieces a, b, c of about 200 m

length around the tooth profile and attac

them with scotch tape (see Fig. ’A’ and ’B’)

⇒ Number the tooth profiles in accordance wi

Fig. ’B’.

⇒ Turn the lead wires only once through th

teeth meshing.

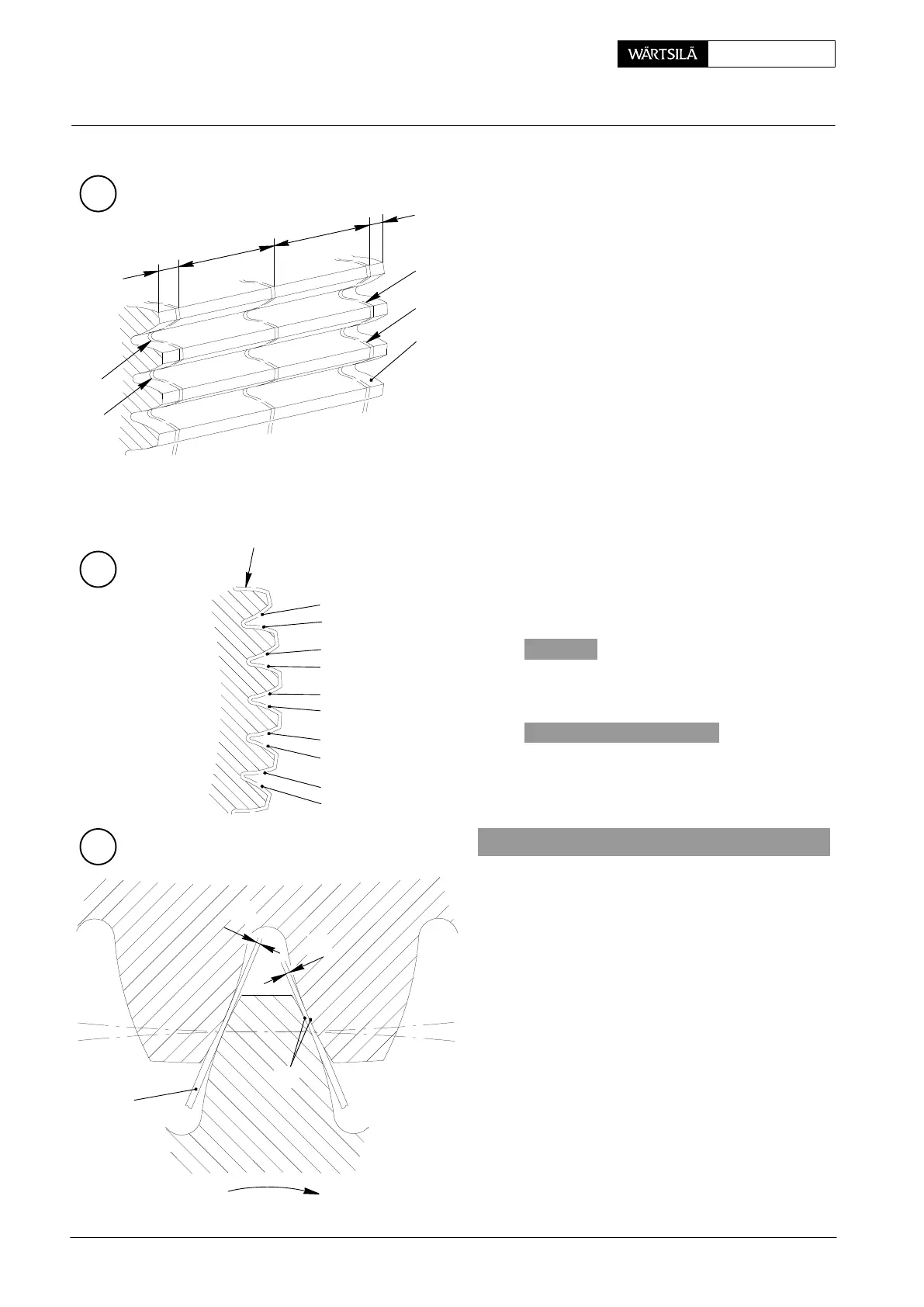

D Lead wire ’c’ (Fig. ’A’) serves to verify tot

tooth backlash ’f’ (Fig. ’C’).

With lead wires ’a’ and ’b’ (Fig. ’A’) the too

profile parallelity is checked.

D Total tooth backlash ’f’ (Fig. ’C’) composes

f

1

and f

2

(thickness of lead wire):

f = f

1

+ f

2

D Obliquity ’Df’ is calculated from the differenc

in thickness of the squashed lead wires alon

driving flanks TF (Fig. ’A’):

Df = a

1

− b

1

or a

3

− b

3

etc.

D The admissible deviation of tooth profile p

rallelity amounts to max. 0.2

o

/

oo

across th

width of the tooth.

4. Checking the running performance

To enable judging the running performance

the gear train after recommissioning, thre

teeth each of the gear wheels are smeare

with a thin coat of oil resisting marking blu

(ink) equally spread. This check is necessa

in order to verify the mating appearance of th

teeth.

One brand of oil resisting marking blue is, f

example, Dykem Layout Red Dx-296.

LEAD WIRE Ø 1,5 mm

a

1

a

3

7

a

c

b

0

1

2

3

4

5

6

...

...

...

TF

c

A

B

C

15 mm

15 mm

=

=

b

1

b

3

f

1

f

2

000.653/93

000.653/93

000.653/93

Checking the Running and Backlash Clearances and Condition of Teeth

2010

Loading...

Loading...