Maintenance

5801−1/A2

RT-flex50-D

Wärtsilä Switzerland Ltd

1/ 2

Tools: Key to Illustrations:

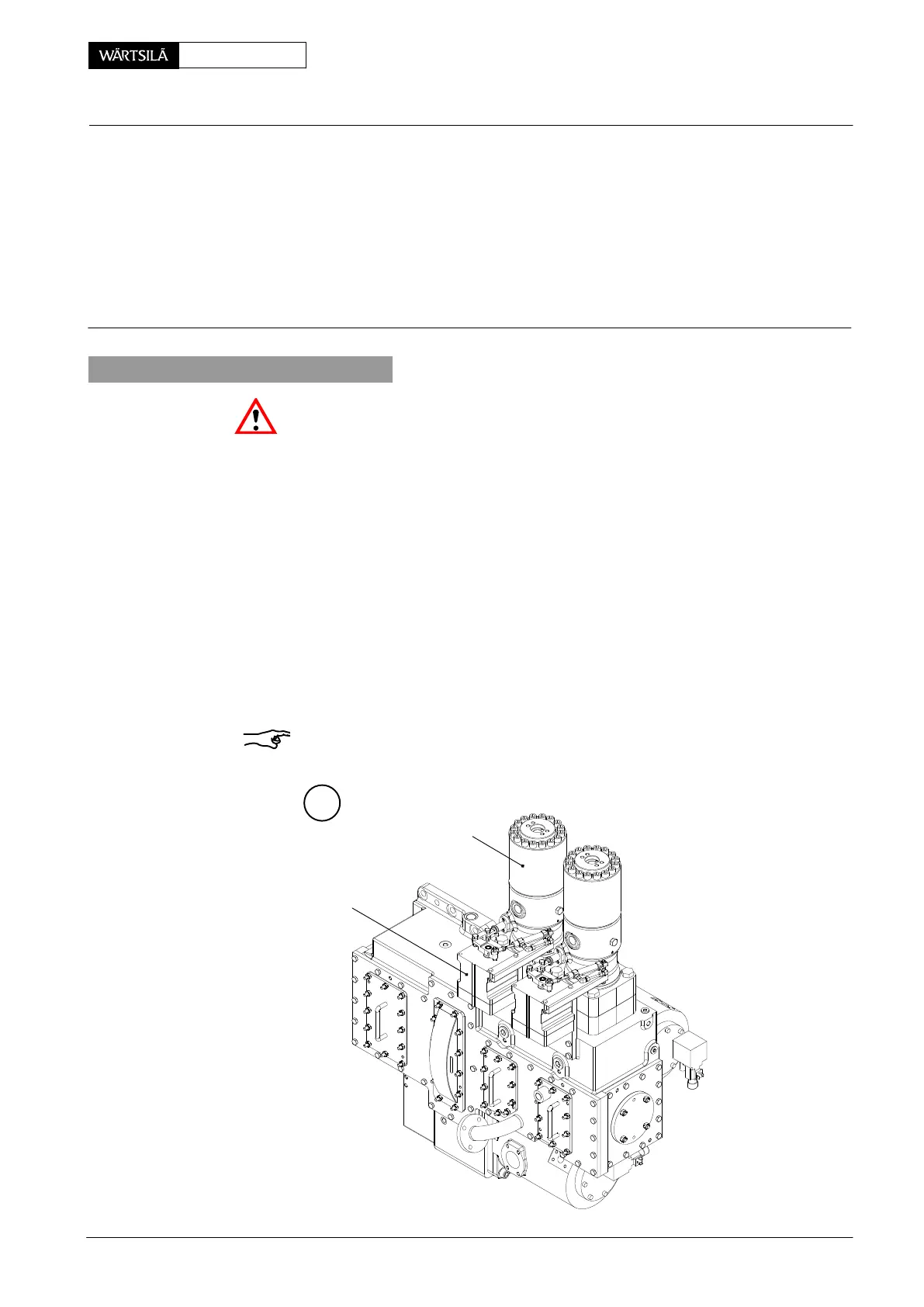

2 Spacers 94555a 1 Fuel pump 8 Connecting element

2 Actuator 9 Toothed rack

3 Output shaft 10 Set screw

4 Damper 11 Self-locking nut

5 Lever 12 Spot-face

6 Clamping sleeve

7 Screw MA Mark

1. General

Attention! The power to the actuator must be interrupted before disconnecting it

from the connecting element (see 9362−1 in the Operating Manual).

After overhauling or fitting a new fuel pump or an actuator according to manufactu-

rer’s instructions, the adjustment of the linkage must be checked and the following

points observed:

D Connecting element 8 and damper 4 (retracted: ’x’ = 190 mm or extended: ’x’

= 240 mm) freely movable and part concerned lubricated with MOLYKOTE

paste G.

⇒ Mark lever position to output shaft with slight center punch strokes ’MA’.

⇒ Center output shaft 3 manually (set point).

⇒ Position lever 5 parallel (view I) with its clamping sleeve 6.

⇒ Center toothed rack, i.e. adjust it to 36 mm on both sides using spacers

94555a.

D Always join lever and regulating rack with connecting element (spot face 12

pointing to lever 5) by means of set screws 8 in good condition and tightened

with their self-locking nuts 11.

Remark: In case of an emergency, i.e. for operation with defective actuator(s) see

0515−1 in the Operating Manual.

A

WCH00245

1

2

egulating Linkage

djusting with Woodward ProAct II − Analog Actuato

2011

Loading...

Loading...