Maintenance3425−1/A1 RT-flex50-D

Wärtsilä Switzerland Ltd

4/ 4

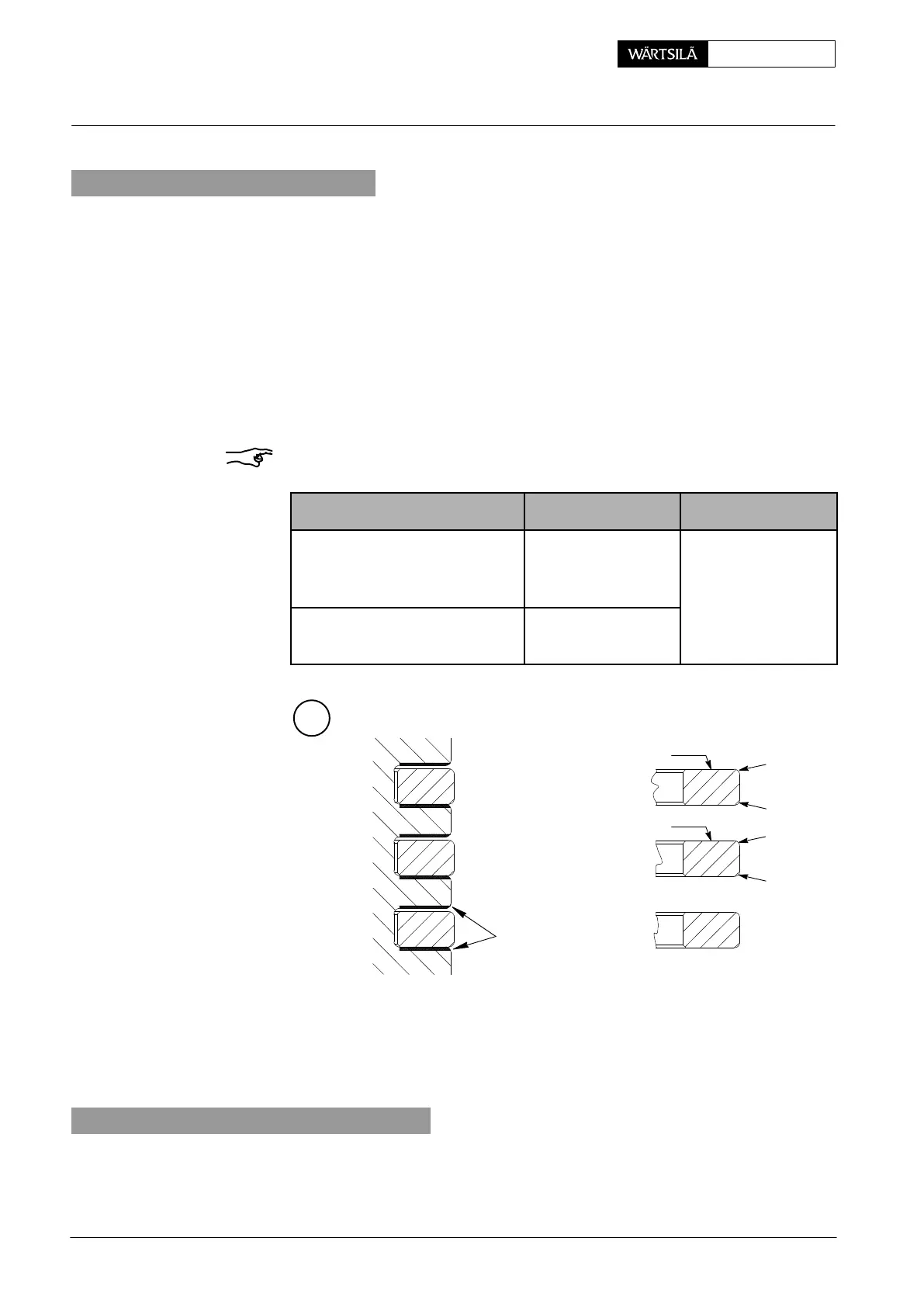

4. Fitting piston rings

D When reusing piston rings, only rings in perfect condition may be fitted, how-

ever in the same position and groove as removed.

⇒ The edges of the ring gap must be rounded off with a radius of 0.5 mm (with

exception of CC coated piston ring).

⇒ Reused piston rings with sharp edges must be rounded off with radii as shown

in the figure below (with exception of CC coated piston ring).

D Always fit piston ring with the marking TOP upwards

(when the piston is assembled the piston rings must be turned such that the

ring gaps are staggered by 180_).

D The chromium plating thickness of a new CC coated piston ring should be

measured and recorded to monitor the wear rate over time.

Remark: New piston rings have to be run-in according to the indications in the

Operating Manual 0410−1.

Ring type Coating / material Application

Uppermost piston ring ’a’

1 x GTP1CC15_Gas Tight chrome-ceramic

coated

for new and fully

honed cylinder liner

as well as for used

cylinder liners in

good conditions

Piston rings ’b’ and ’c’

2 x SCP1RC15_Straight Cut

running-in coating

C

a

b

c

003.831/96

r 2

TOP

TOP

r 2

r 2

r 2

CHROMIUM

PLATING

5. Storage and handling of piston rings

Store the piston rings in a dry place and lay them horizontally on a flat surface,

keeping them in their original packing. Handle with care when preparing for use

and avoid any hard contact against other objects.

2010 / 50−D

Piston: Checking Piston Ring Wear

Loading...

Loading...