Maintenance

2751−3/A1

RT-flex50-D

Wärtsilä Switzerland Ltd

5/ 5

5. Checking the valve seat

After grinding it is necessary to check whether the new

re-ground valve makes correct contact with the valv

seat. For this the spindle head seat face is spread with

thin coating of blueing paste, then inserted vertically in

the valve guide bush.

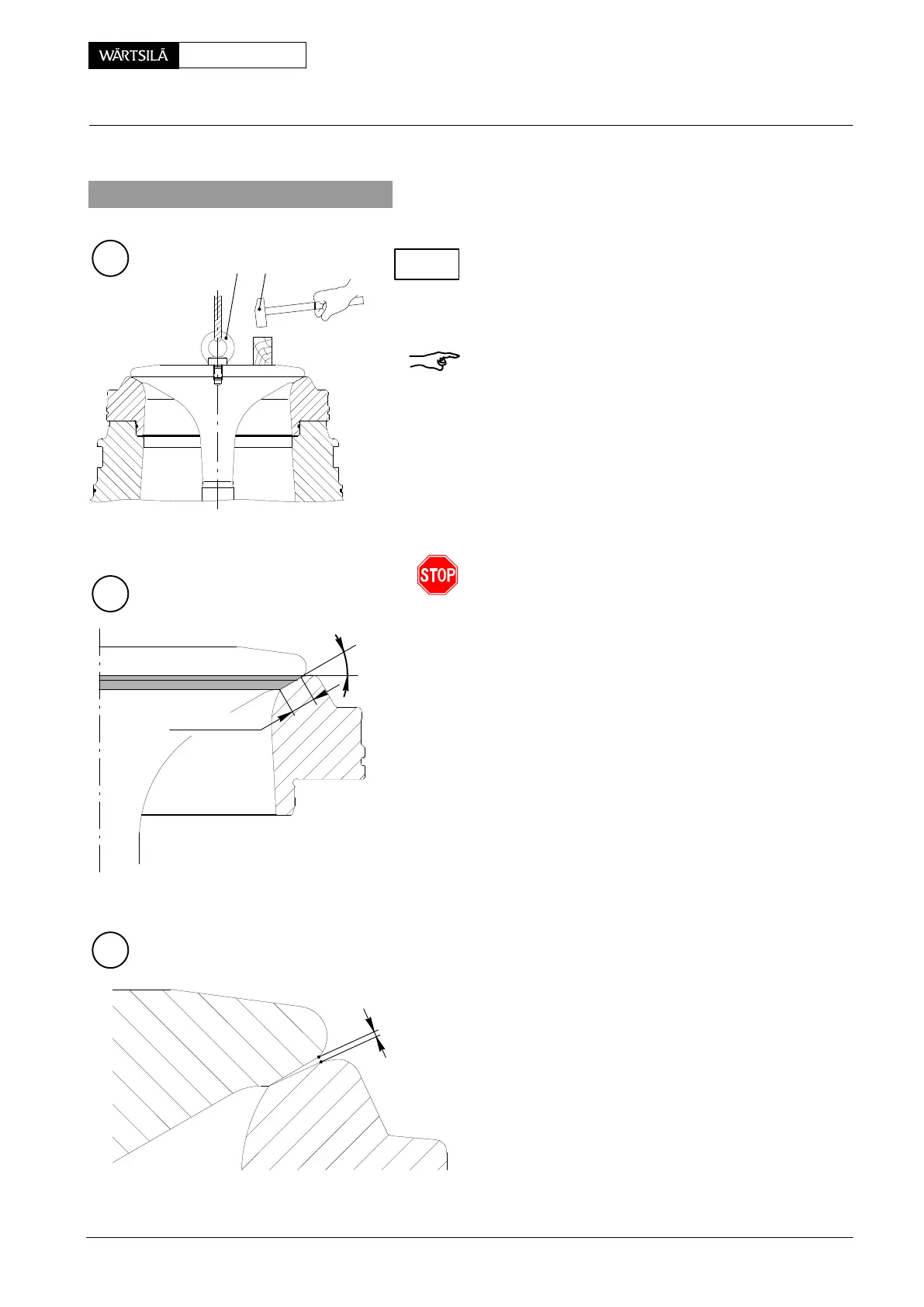

Remark: The angle difference is chosen such that in th

hot operating condition the valves makes contact b

50−100% from the outer edge (Fig. ’F’). The bluein

check should show that the cold valve makes conta

only from inside around the whole circumference. Th

angle difference can be checked at gap ’S’ on the out

edge with a feeler gauge (Fig. ’G’).

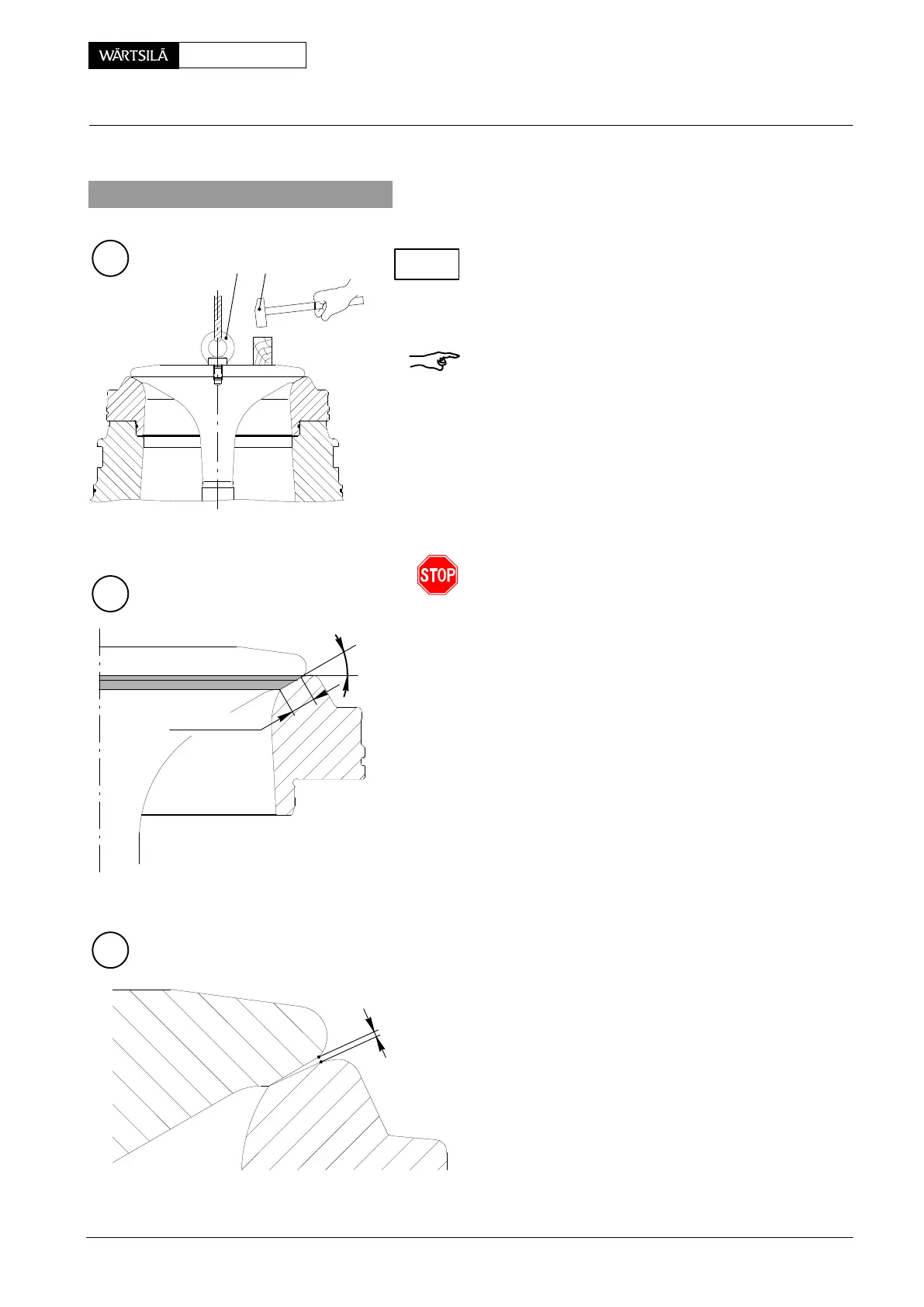

⇒ The blueing on the valve seat must be checked b

tapping the valve head three or four times with

hammer on a wooden block! (Fig. ’E’).

Do not rotate the valve spindle on the valve se

face, as this risks seizure of the seating.

CHECK

F

G

30

2’

+

0

_

HARC

E

50−100%

003.455/00

003.456/00

003.457/00

S = 0.029 − 0.048 mm

Exhaust Valve: Replacing and Grinding the Valve Seat

2010

Loading...

Loading...