Maintenance1903−1/A2 RT-flex50-D

Wärtsilä Switzerland Ltd

4/ 5

Tensioning in one procedure:

⇒ Connect pre-tensioning jacks with hydraulic unit 94942.

⇒ Actuate the hydraulic unit until bubble-free oil flows out through the vent

screws. Close the vent screws.

⇒ Raise pressure to 100 bar, keep it constant, and firmly tighten the two upper

tie rod nuts 3 with rod 94005b.

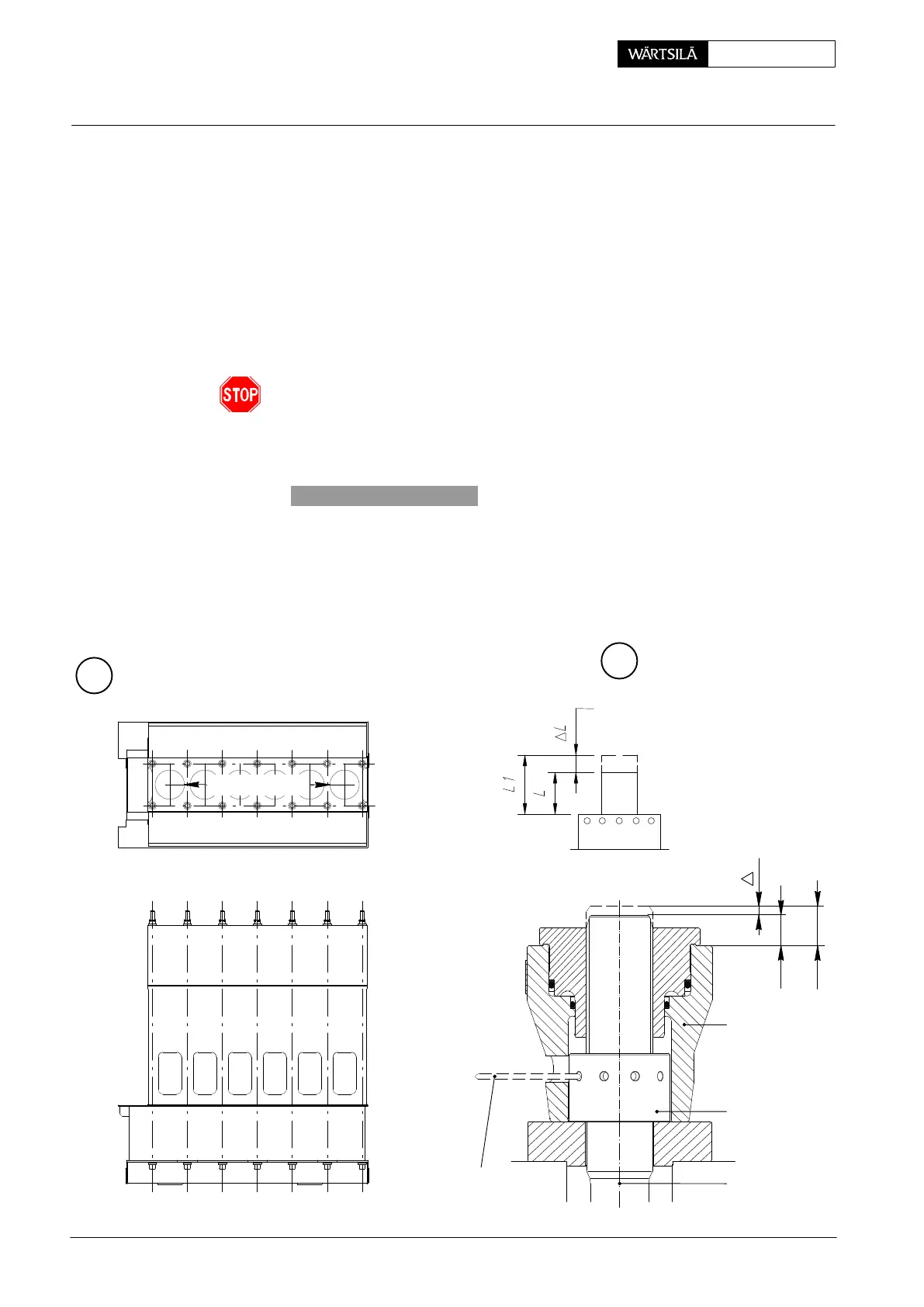

⇒ Measure and record distance ’L’ (the measurements can be taken directly on

the mounted pre-tensioning jacks, i.e. from top edge of tie rod 7 to cylinder 4).

⇒ Subsequently tension tie rods with 1500 bar, keep it constant and firmly tight-

en the two upper tie rod nuts 3 with rod 94005b.

Never move pistons 5 of the pre-tensioning jacks further up than to the red limiting

grooves ’BN’.

⇒ Measure again distance ’L’ and record it as ’L

1

’.

The tie rods are correctly tensioned with 1500 bar when the following reference

value of a total elongation nL (’L

1

’−’L’) is measured:

nL = 11.0 ... 12.5 mm

⇒ Release pressure to ’0’.

⇒ Proceed in the same way following the required sequence for all tie rods b/b,

c/c, d/d ect.

⇒ After completing the tensioning, smear the protruding thread portions of all the

tie rods lavishly with acid-free grease and fit protection covers 8.

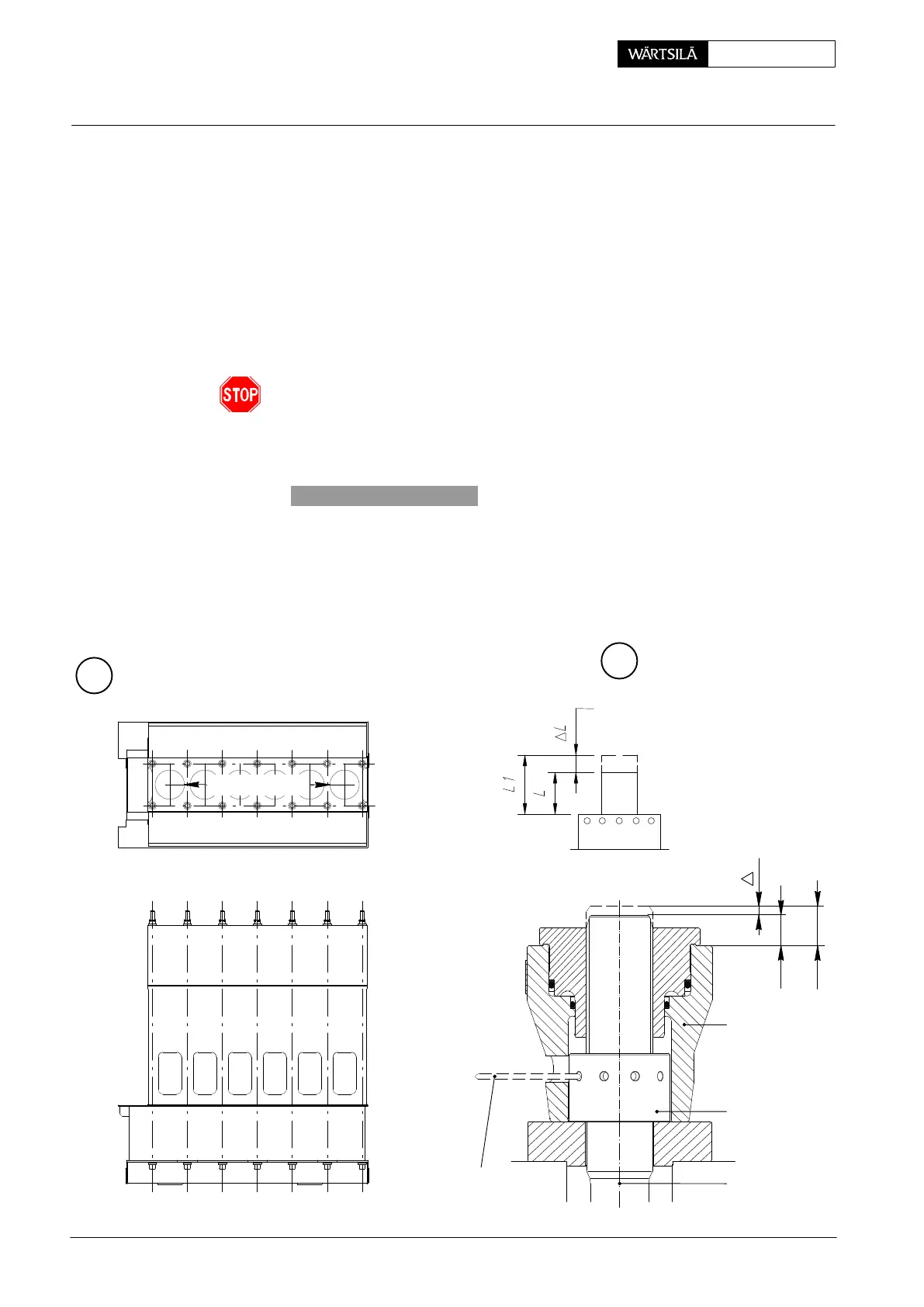

B

AFT

END

FREE

END

ecab dfg

ecab dfg

SEQUENCE

C

94005b

TIE ROD

ELONGATION

WCH00754

WCH00668

L

L

L

1

3

4

7

Checking the Pre-tension and Tensioning the Tie Rods with M72x6 Thread Diamete

2012-07

Loading...

Loading...