Maintenance3303−3/A1 RT-flex50-D

Wärtsilä Switzerland Ltd

6/ 6

3. Fitting the bearing shell

Fitting of the bearing shells is carried out analogously to the removal but in reverse

sequence, whereby attention must be paid to the following:

D The surface of the crosshead pin must be in perfect condition.

D The contact surfaces of the shell rear side and the bearing bore must be free

from any damage.

D While fitting bearing shell prevent dirt or foreign particles from entering be-

tween the shell rear surface and its seating! Immediately before inserting the

bearing shells wipe them with a slightly oily hand.

D The bearing shell should be placed in the connecting rod head such that it pro-

trudes by the same distance at both ends of the separating face.

This protrusion is a must and under no circumstances must the separating

face of the bearing shell be filed to reduce it!

3.1 Fitting a new top end bearing shell

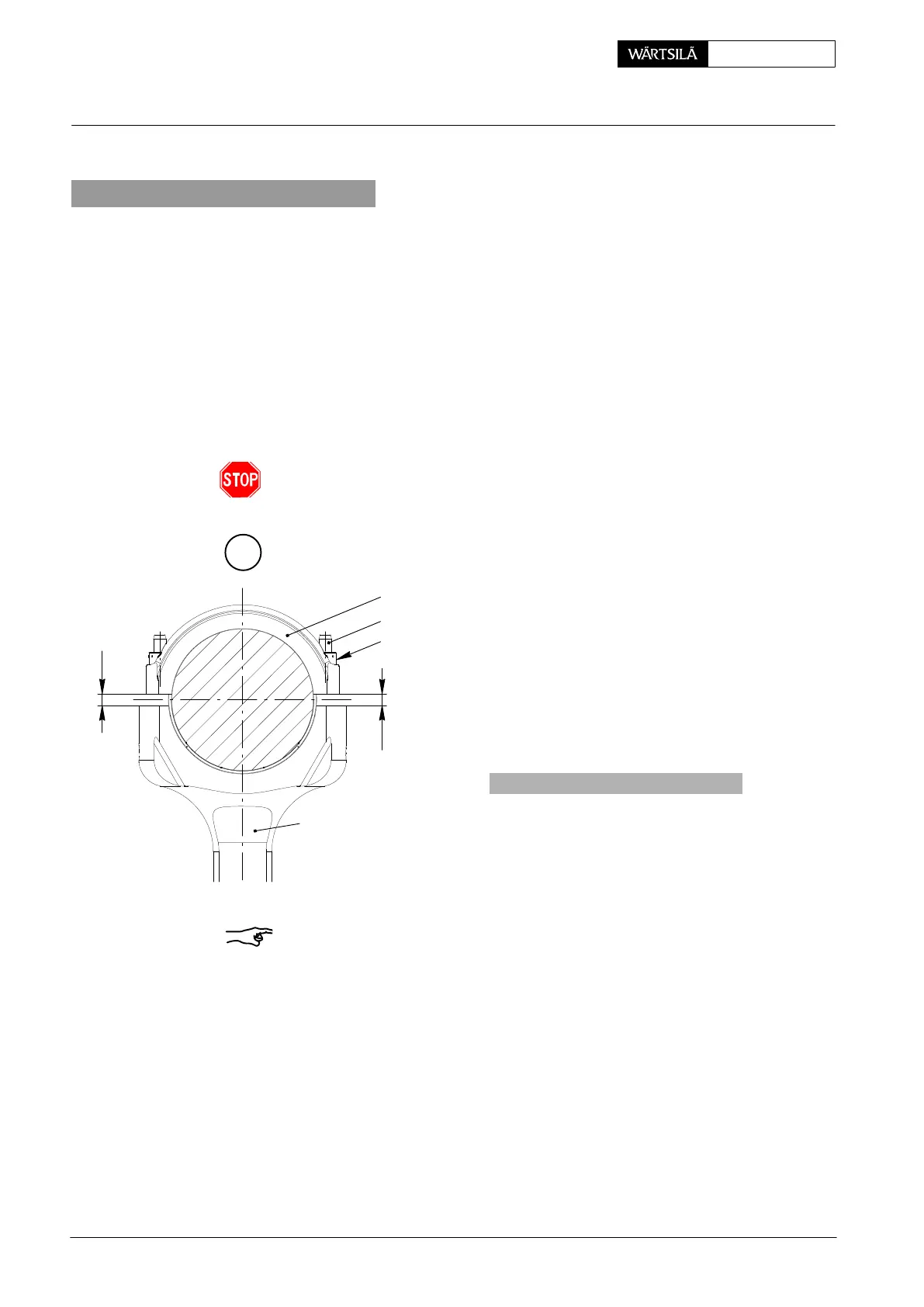

⇒ Proceed as described in section 3, however protr

sion x

1

+ x

2

must be measured prior to tension co

necting rod studs 12.

3.1.2 Measuring the protrusion

⇒ Hand-tighten nuts 4 with a round bar and measu

the protrusion (of a new bearing shell):

x

1

+ x

2

= approx. 0.35 − 0.43 mm

G

12

2

x

2

x

1

4

5

013.629/05

Remark: Above measuring checks must be carried out when fitting a new bearing

shell. For this the bearing shell is placed in position, the bearing cover fitted and the

nuts tightened by hand with a round bar.

Prior to final assembly smear the running surface lavishly with clean bearing oil.

Should, however, the engine have to be frequently turned after the fitting of the

bearing, or should a re-start of the engine not be immediately planned, then

instead of bearing oil a mixture of

2

/

3

steam-engine cylinder oil and

1

/

3

normal bea-

ring oil should be used. Special oils suited to this purpose are also available from

reliable suppliers.

2010

Inspection, Removal and Fitting of Top End Bearing

Loading...

Loading...