Maintenance

3303−3/A1

RT-flex50-D

Wärtsilä Switzerland Ltd

1/ 6

Tools: Key to Illustrations:

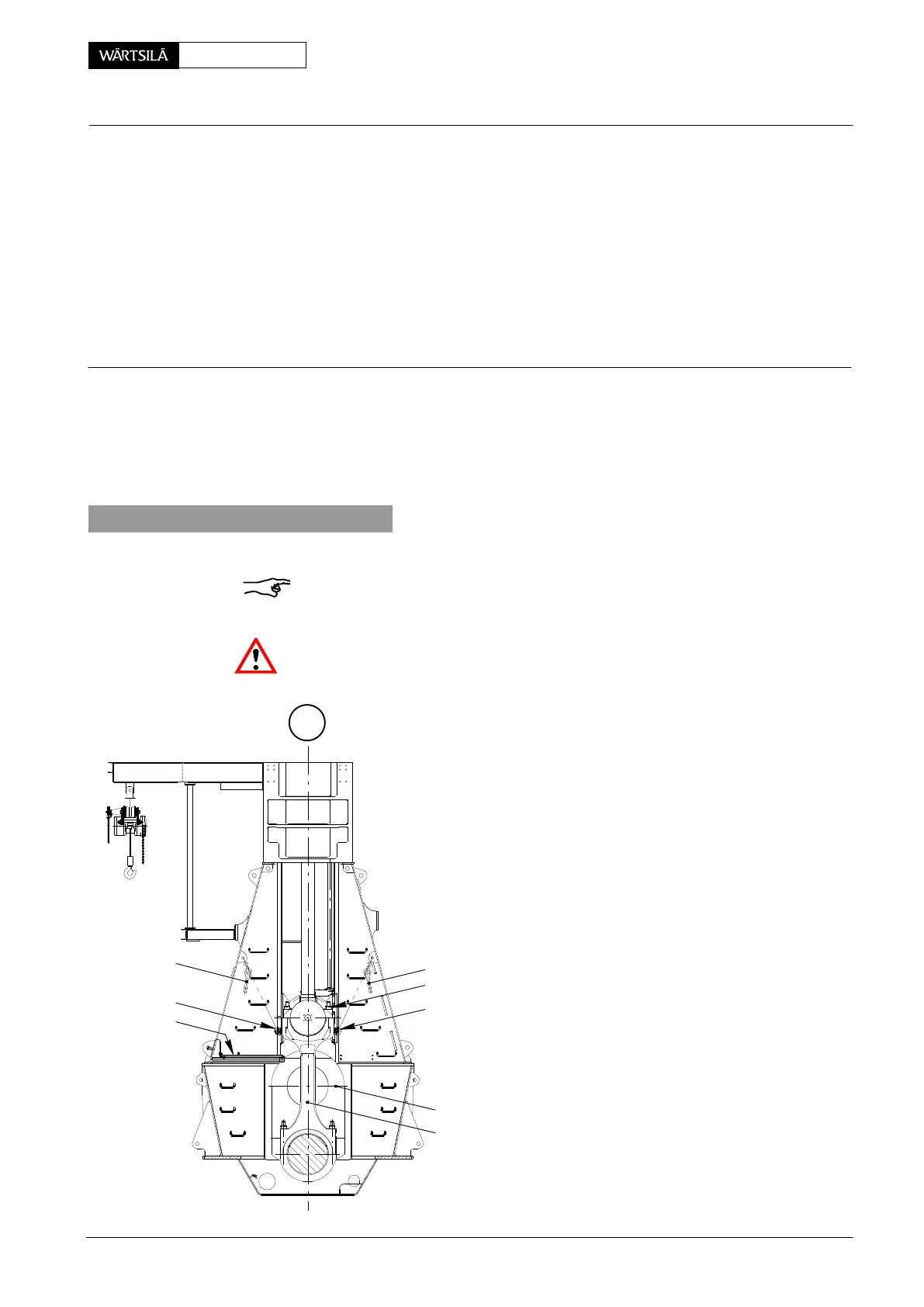

1 Working platform 94142 1 Crankshaft 10 Allen screw

4 Retaining pins 94323 2 Connecting rod 11 Bearing shell

1 Lifting plate 94324 3 Piston rod 12 Connecting rod stud

2 Lifting rings 94332 4 Nut 13 Spur-geared chain block

1 Stop plate 94370h 5 Bearing cover

6 Guide shoe HZ Lifting tackle

7 Screw H

1

... Lifting tackle

8 Cylinder block RC RUD-eye bolt

9 Guide way R

1

... RUD-eye bolt

Overview

1. Inspection of bearing shell 1/6.............................

2. Removal of bearing shell 5/6...............................

3. Fitting the bearing shell 6/6................................

1. Inspection of bearing shell

The bearing shell can be examined with piston in situ or removed.

Remark: Pay attention to:

− General Guidelines for Lifting Tools 0012−1.

− Utilization of Working Platform 3301−1.

Risk of accident! During all the work it must be ensured that the crankshaft does

not turn unintentionally.

⇒ Turn crank of the respective cylinder to B.D.C

⇒ Install working platform 94142.

⇒ Screw RUD-eye bolts R

1

and R

2

into the co

necting rod head on both sides.

⇒ Connect lifting tackles H

1

and H

2

(lifting c

pacity 1500 kg each) to RUD-eye bolts R

1

an

R

2

and tauten them.

A

4

94142

013.626/05

H

2

R

2

H

1

2

1

R

1

onnecting Rod

nspection, Removal and Fitting of Top End Bearing

2010

Loading...

Loading...