Maintenance

3303−1/A1

RT-flex50-D

Wärtsilä Switzerland Ltd

1/ 5

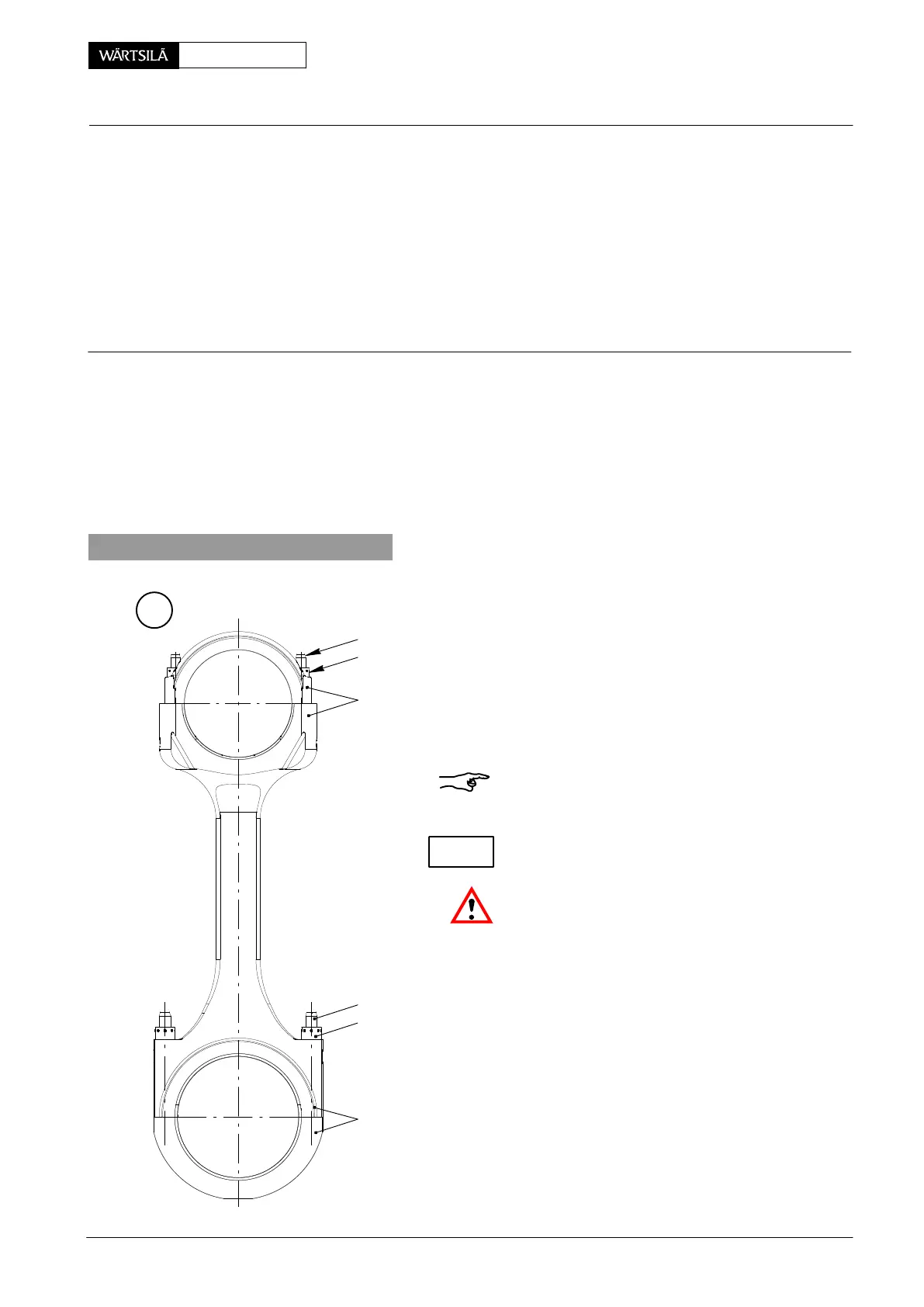

Tools: Key to Illustrations:

1 Feeler gauge 94122 1 Stud of top end bearing 9 Cylinder

2 Pre-tensioning jacks 94314 2 Nut

2 Distance bushes 94314a 3 Top end bearing

2 Pre-tensioning jacks 94315 4 Stud of bottom end bearing

1 Connection block 94934 5 Nut BN Limiting groove

1 Hydr. distributor 94934a 6 Bottom end bearing KO Slot

3 HP hoses 94935 7 Vent screw RS Round bar

1 Hydraulic unit 94942 8 Piston SA Gap

Overview

1. General 1/5...............................................

2. Loosening the stud of bottom end bearing 2/5...............

3. Tensioning the stud of bottom end bearing 3/5..............

4. Loosening the stud of top end bearing 4/5..................

5. Tensioning the stud of top end bearing 5/5..................

1. General

Remark: We recommend to follow the instruction

9403−4 referring to the application of hydraulic pr

tensioning jacks to screwed connections.

Check that nuts 2 or 5 turn freely on the threads.

Attention! Never turn the crankshaft (with the tur

ing gear) as long as the pre-tensioning jacks a

mounted on the connecting rod studs!

CHECK

A

1

2

3

4

5

6

013.378/05

701.013.378

onnecting Rod

oosening and Tensioning the Connecting Rod Studs

2010

Loading...

Loading...