Maintenance

5612−1/A1

RT-flex50-D

Wärtsilä Switzerland Ltd

1/ 3

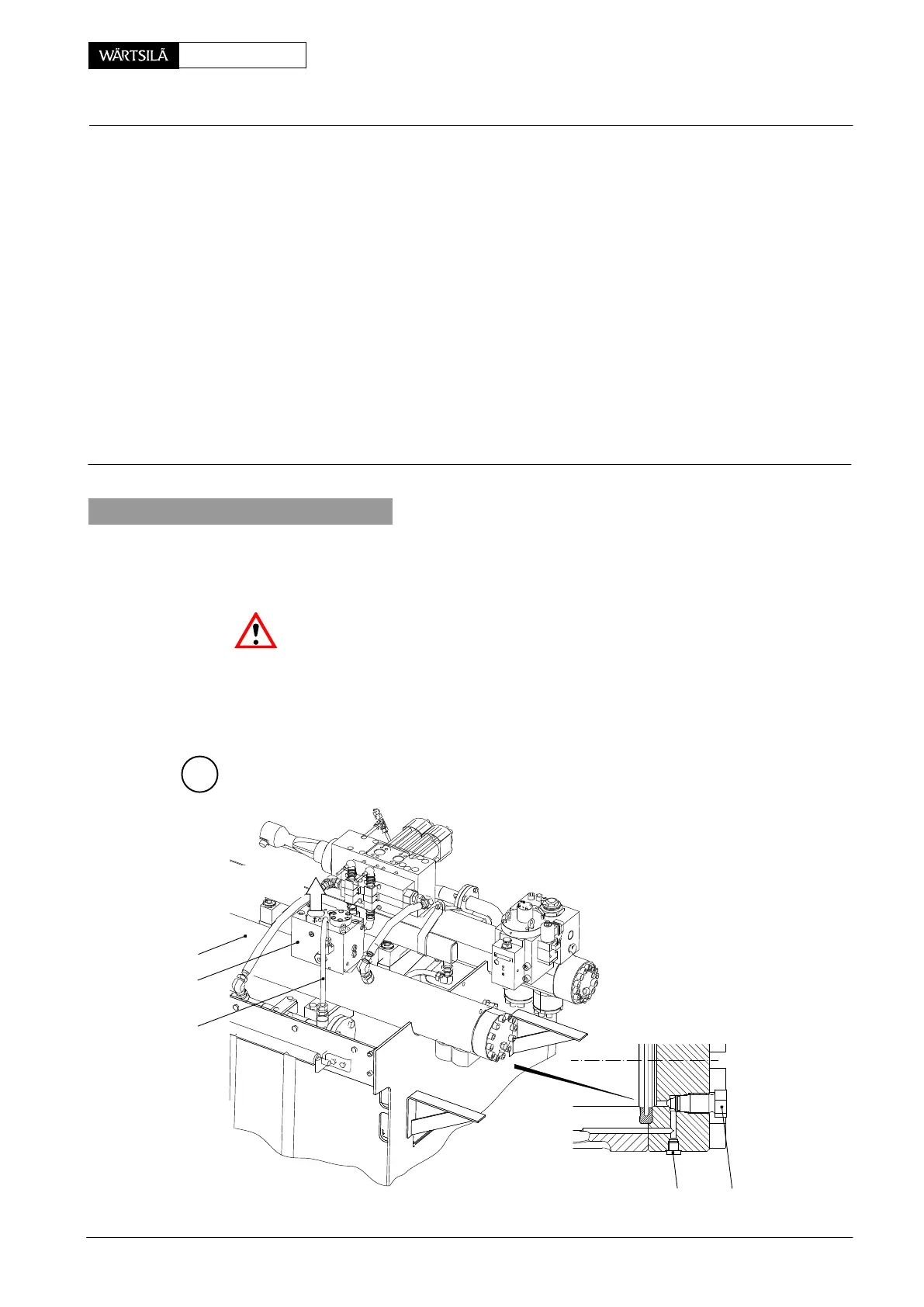

Key to Illustrations:

1 Servo oil rail 15 Filter holder

2 Drain screw 16 Seal

3 Screw plug 17 Circlip

4 Valve control block 18 Oil filter

5 Allen screw M16x160 19 Orifice

6 Piston 20 Rail valve (pre-control valve)

7 Sealing flange 21 Allen screw M4x16

8 O-ring & back-up ring 22 Return pipe

9 Pan head screw M5 23 Dowel pin

10 Cover 24...26 O-rings

11 Allen screw M10x40

12 Compression spring

13 Slide rod RC Eye bolt

14 Screw plug with seal AF Seating surface

1. General

The piston and slide rod should be checked at random according to Maintenance

Schedule 0380−1.

When working on the exhaust valve control unit the engine has to be stopped.

Attention! Servo oil pipings must be pressureless and properly drained by means

of carefully opening drain screw 2 and screw plug 3.

Follow the instruction in 0520−1 of the Operating Manual without fail!

The respective work station must be clean; welding and grinding should not be

done nearby!

TO EXHAUST VALVE

SEE 8460−1

A

2

1

22

3

4

WCH00694

xhaust Valve Control Unit

emoval, Fitting, Dismantling and Assembling

2011-12

Loading...

Loading...