Maintenance

2751−1/A1

RT-flex50-D

Wärtsilä Switzerland Ltd

7/ 7

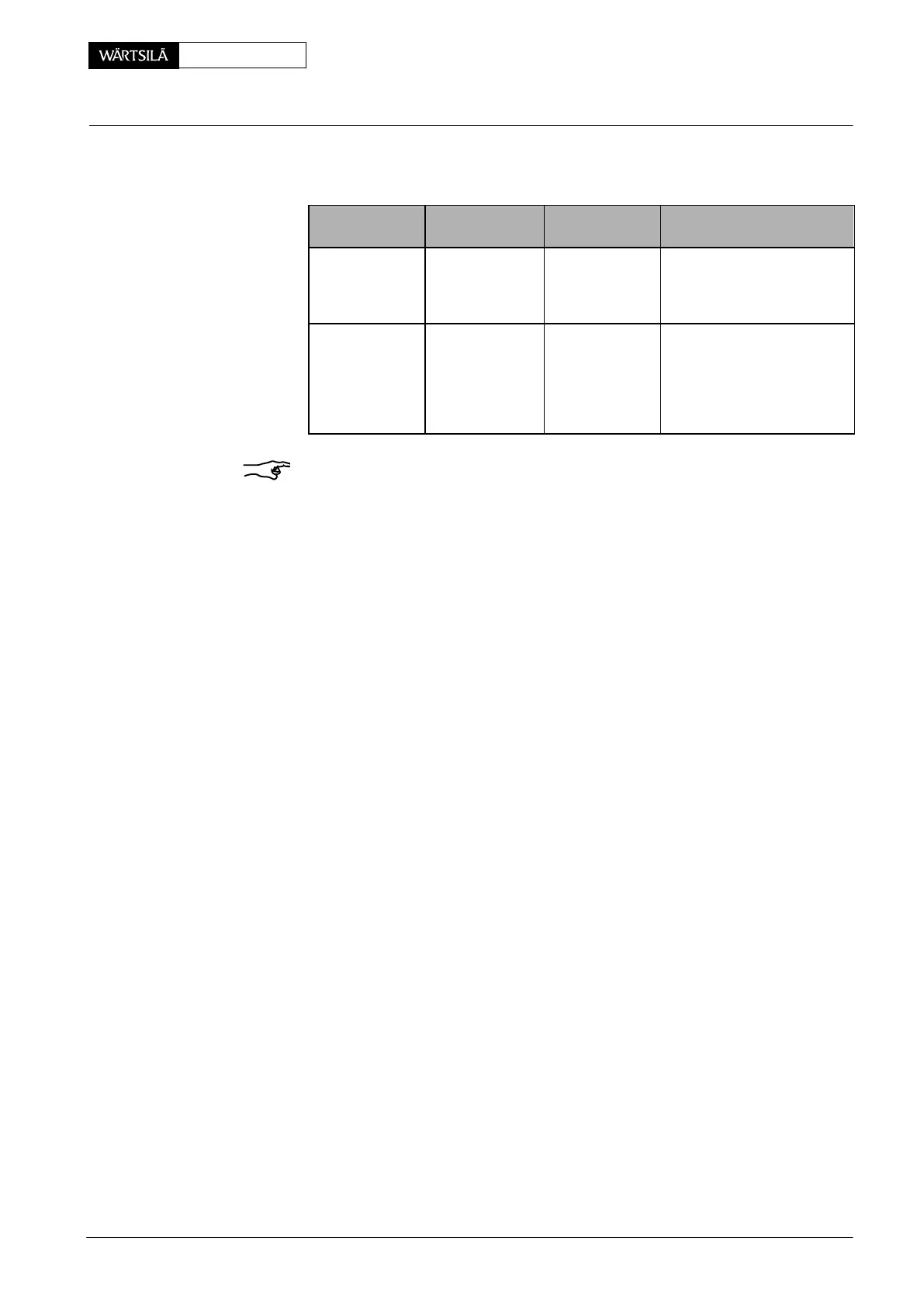

3.2 Recommended jointing compound and adhesive primers

Jointing

compound

Hardener Adhesive

primer

Manufacturer

Elastosil

RT 622 A

RT 622 B G 790 Wacker-Chemie Gmbh

Geschäftsbereich Silicone

Hanns-Seidel-Platz 4

D-81737 München

Silcoset

105 RTV

Silcoset

Curing Agent A

Silcoset Primer AMBERSIL LTD

Wylds Rd

Bridgwater

Somerset

TA6 4DD

Uk-Great Britain

Remark: Mixing and applying of the jointing compounds must be done according

to the instruction of the respective manufacturer.

Products of other manufacturers are also allowed when fulfilling the below specifi-

cation:

− Containing no acid, e.g. no acetic acid.

− Resistant to oil, marine diesel oil, heavy fuel oil and water at a permanent tem-

perature of approximately 100 _C.

− Short age hardening time, i.e. at least 24 hours under ISO standard reference

conditions.

− Well flowing to properly fill out the annular space, in order to avoid the creation

of any hollow space.

− Good adhesion on adhesive-primed metallic surface.

− Easy to prepare and combine.

− None or only minimal surface shrinkage.

− The jointing compound must remain elastic, as a cylinder cover stud may be

removed at any given time.

2012-07

Removal and Fitting of Exhaust Valve, Replacing of Waisted Studs

Loading...

Loading...