Maintenance1132−2/A1 RT-flex50-D

Wärtsilä Switzerland Ltd

10/ 17

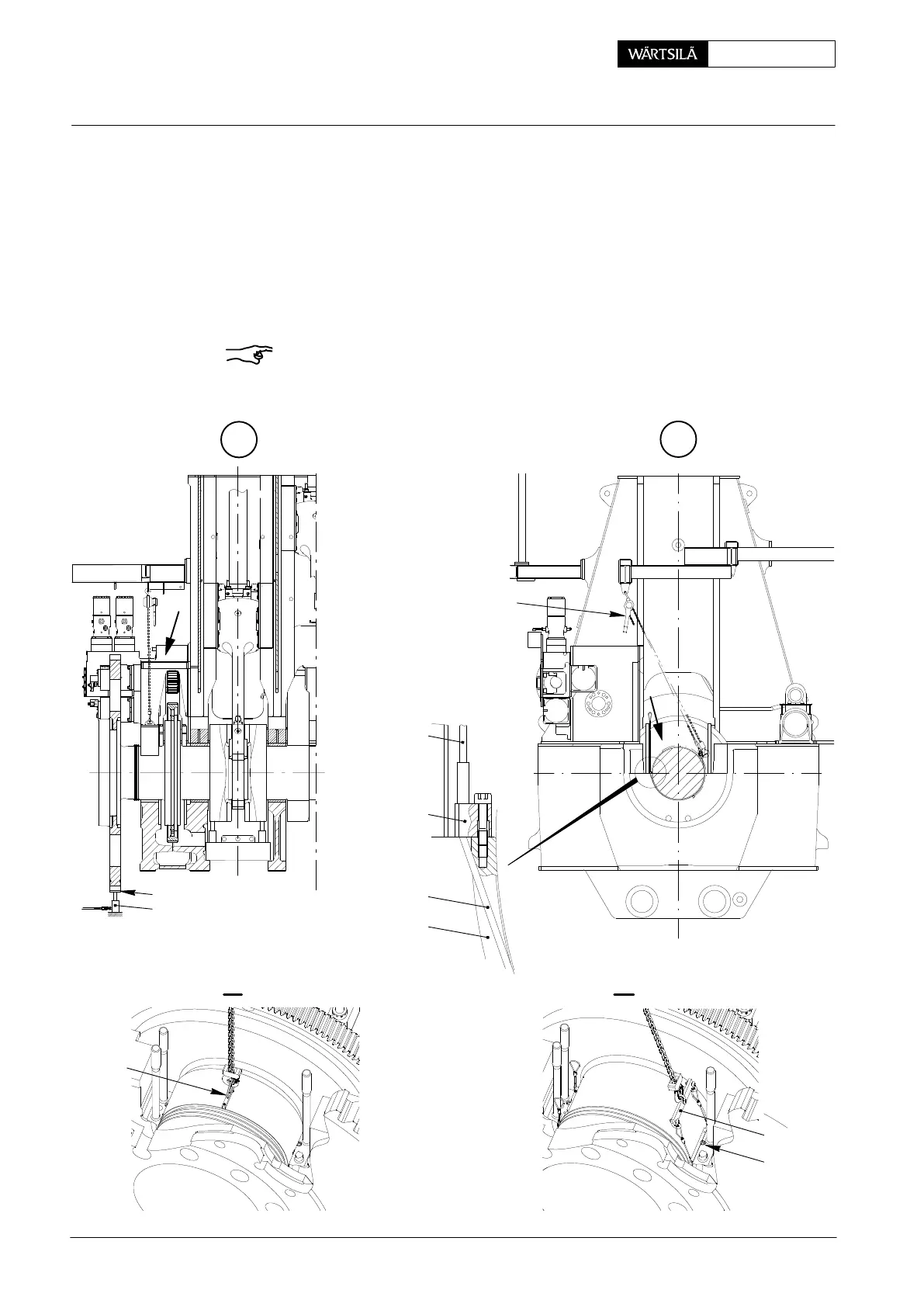

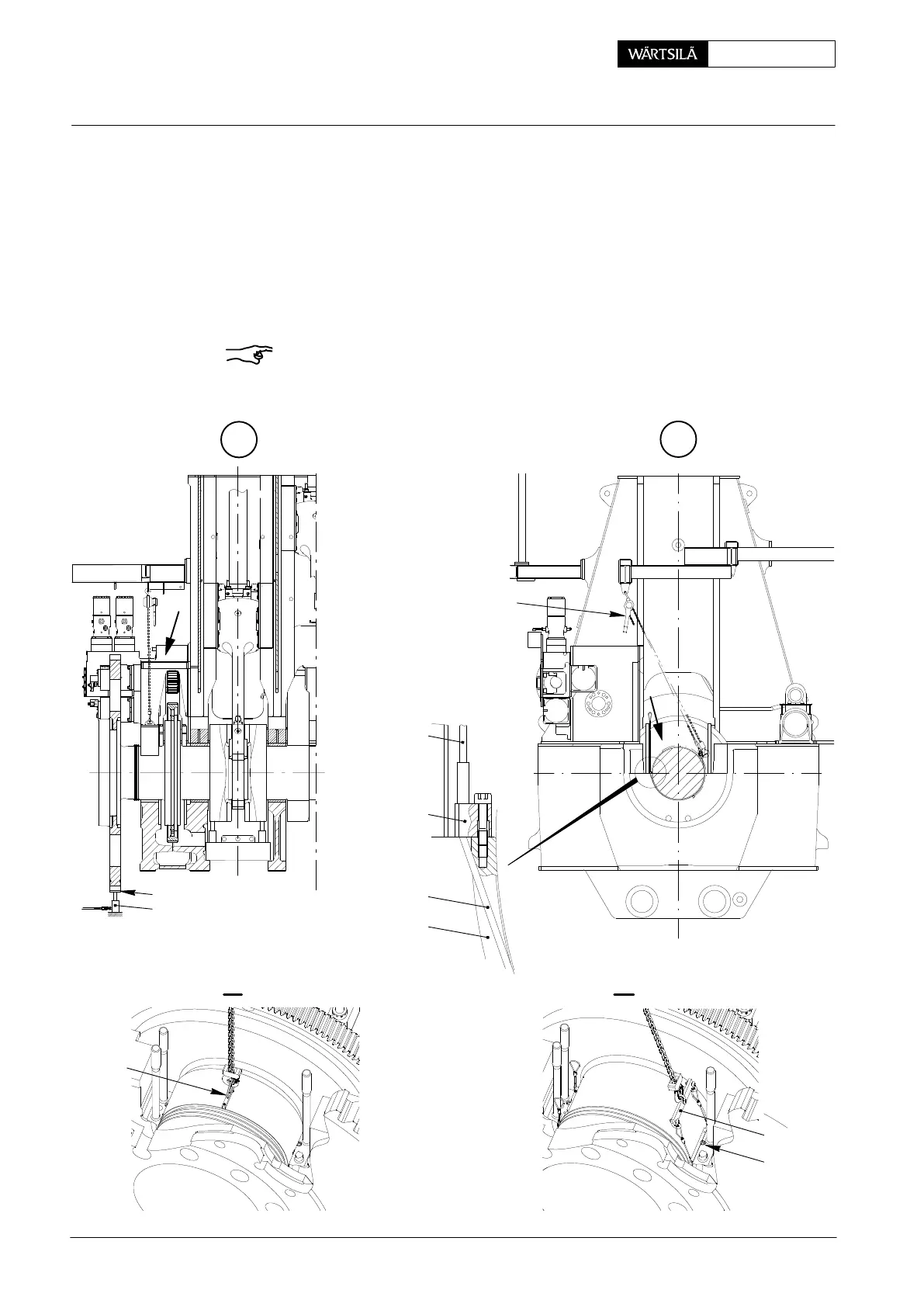

5.3 Turning out and removal of lower bearing shell No. 1

D Crankshaft lifted up by approx. 0.2 mm (see paragraphs 5.1 and 5.2).

⇒ Fasten manual ratchet H

1

to the platform.

⇒ Remove Allen screw 5 from bearing girder on exhaust side. Fasten turning-

out device 94118a to bearing shell 4a, lead ropes ’a’ along the lateral edges of

the bearing shell to the other side and connect them with device 94119b.

⇒ Turn out bearing shell using manual ratchet H

1

until transportation tool

94116a (WLL 50 kg) can be fitted.

Remark: If a bearing shell jams during turning out, device 94119b must be fas-

tened to the two opposite wire ropes ’b’ of turning-out device 94118a. Subsequent-

ly draw the bearing shell back into the initial position until it is freed and then pro-

ceed again with the removal of the bearing shell.

I

PROTECTION

16

J

94118a

94119b

II

018.604/09

H

1

I

III

4a

a

5

b

018.601/09

4116a

2010 / 50−D

Removal and Fitting of a Main Bearing

Loading...

Loading...