Maintenance0352−2/A1 RT-flex50-D

Wärtsilä Switzerland Ltd

2/ 2

2. Waisted studs

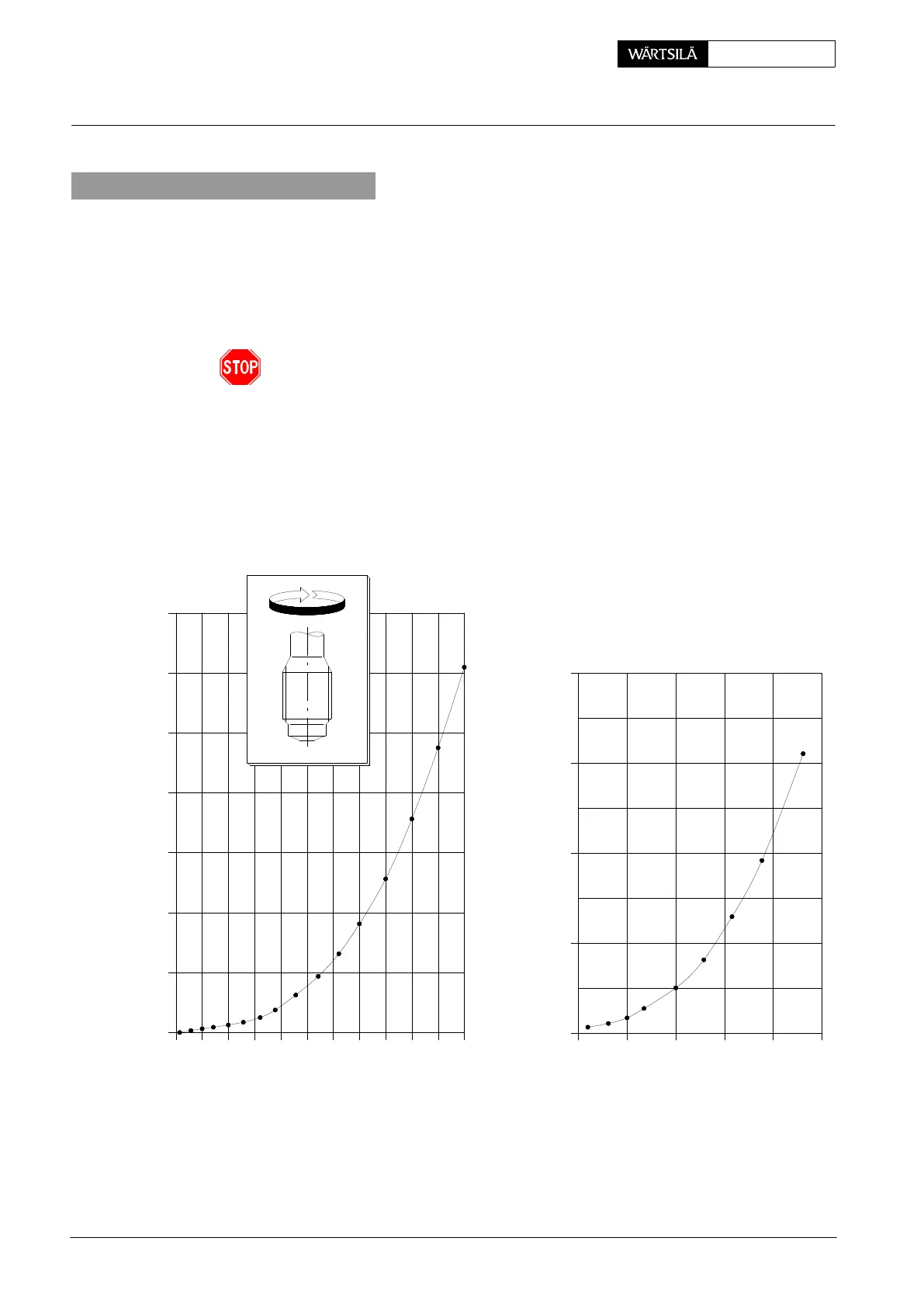

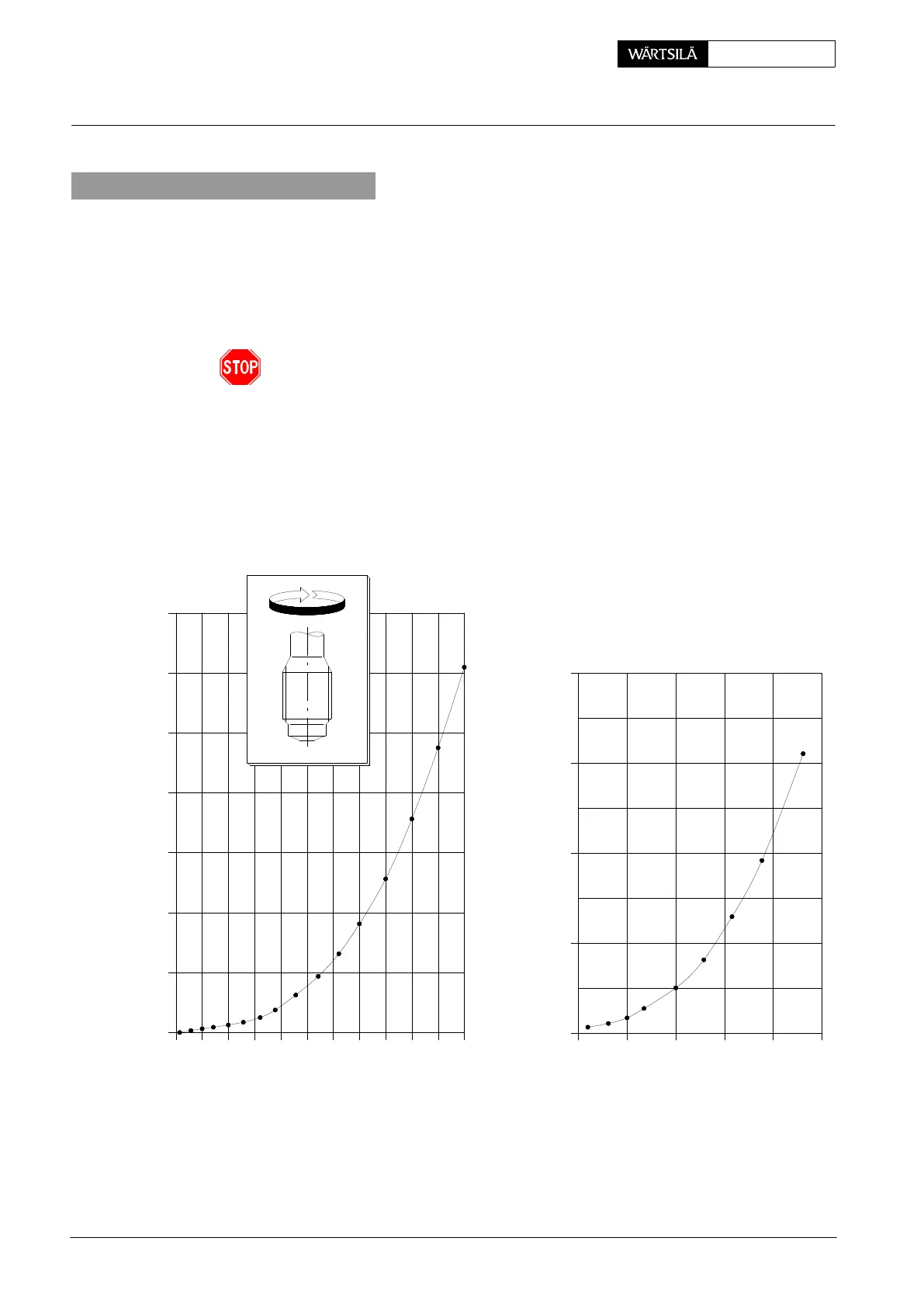

Waisted studs must be tightened according to the values in the following diagram.

D Before fitting a waisted stud clean its thread and corresponding tap hole. The

sealing faces must be degreased (e.g. using white spirit) and subsequently

primed.

D Screw in the waisted stud without lubricant on the thread right to the bottom of

the tap hole, and tighten. Always utilize a stud driver or two nuts.

Tools like a pipe wrench etc. which would damage the stud shank must never be

used.

D For the protection of the waisted stud in the cylinder block and cylinder cover,

fill the annular space above the thread with a non-hardening jointing com-

pound (see 2751−1).

TIGHTENING TORQUE FOR WAISTED STUDS

TIGHTENING TORQUE [Nm]

400

300

200

10

100

20 30 40 50 6

3500

3000

2500

2000

1500

1000

0

500

10 3020 40 50 60

0

001.769/97

70 80 100 11090 120

THREAD DIAMETER [mm]

Tightening Values of Standard Screwed Connections

2010

Loading...

Loading...