Maintenance

3130−1/A1

RT-flex50-D

Wärtsilä Switzerland Ltd

1/ 4

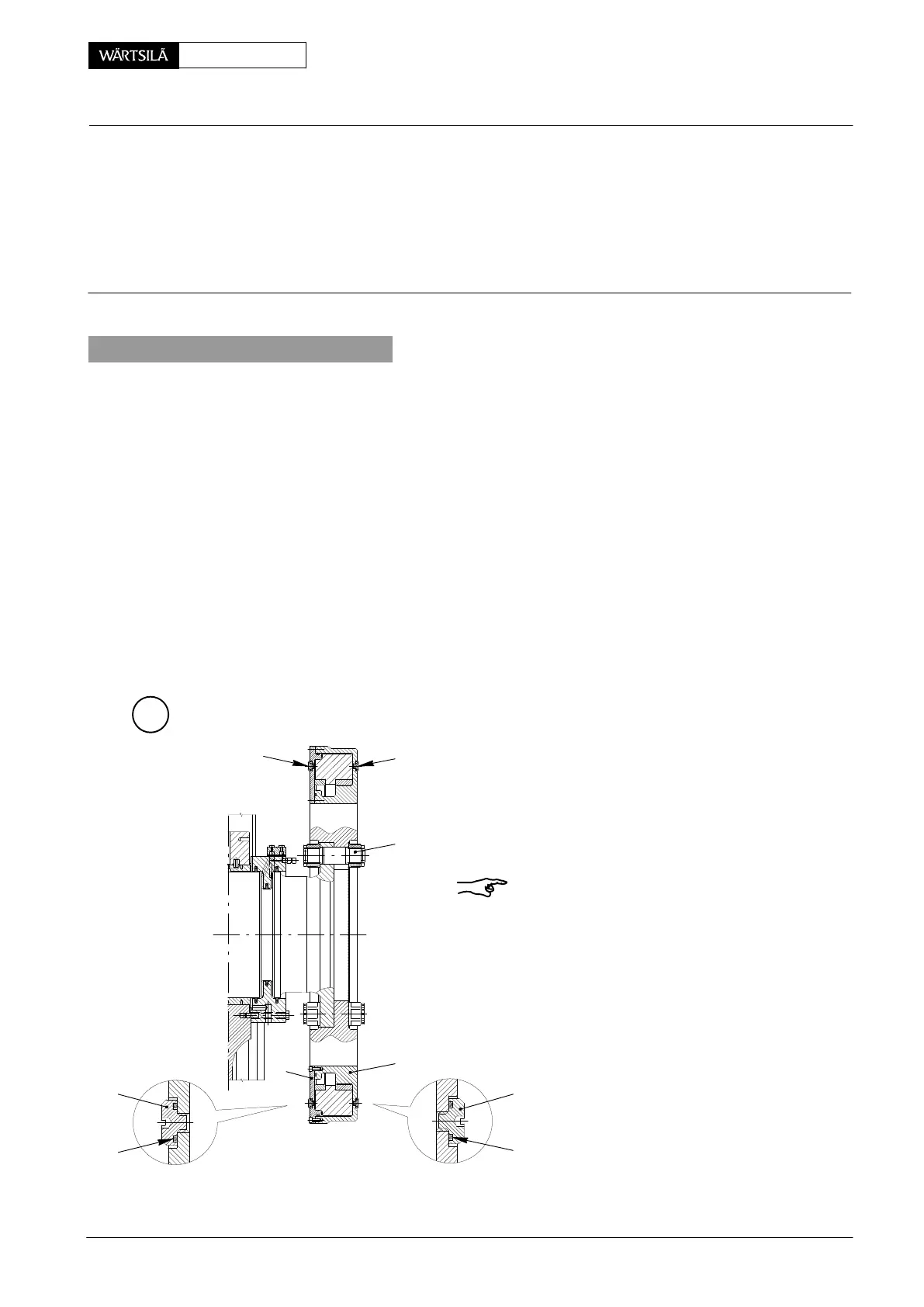

Key to Illustrations:

1 Casing trough 6 Coupling bolt

2 Casing cover 7 Cap nut

3 Screw plug

4 O-ring KS Secured by centre punch mark

5 Sealing ring PB Sample container

1. General

Viscous vibration dampers manufactured by Hasse & Wrede, Metaldyne Interna-

tional UK, STE Schwingungstechnik and Geislinger can be mounted at the free

end of the crankshaft and in case of RTA engines as well at the free end of the cam-

shaft.

The service life of a vibration damper is largely dependent on the speed range in

which the engine is run. Wear of the inner parts as well as changes in the silicone

oil properties can reduce the effectiveness of the damper. By periodic examination

of the silicone oil the makers of the vibration damper can draw conclusions on its

condition.

The silicone oil must be examined for the first time after about 15 000−18 000 oper-

ating hours. Future intervals for examinations depend on the result of these first

findings.

Special sample containers ’PB’ (Fig. ’B’) can be obtained from the vibration

damper makers.

Remark: Before taking a sample, or before wor

ing on a vibration damper, always follow first the

structions of the vibration damper manufacture

In casing trough 1 and casing cover 2, two oil sam

pling holes are carefully closed and sealed w

screw plugs 3.

6

3

1

3

2

3

4

3

4

A

013.133/05

ibration Damper

aking a Silicone Fluid Sample

2010

Loading...

Loading...