Maintenance3326−1/A1 RT-flex50-D

Wärtsilä Switzerland Ltd

2/ 3

2. Checking the clearances

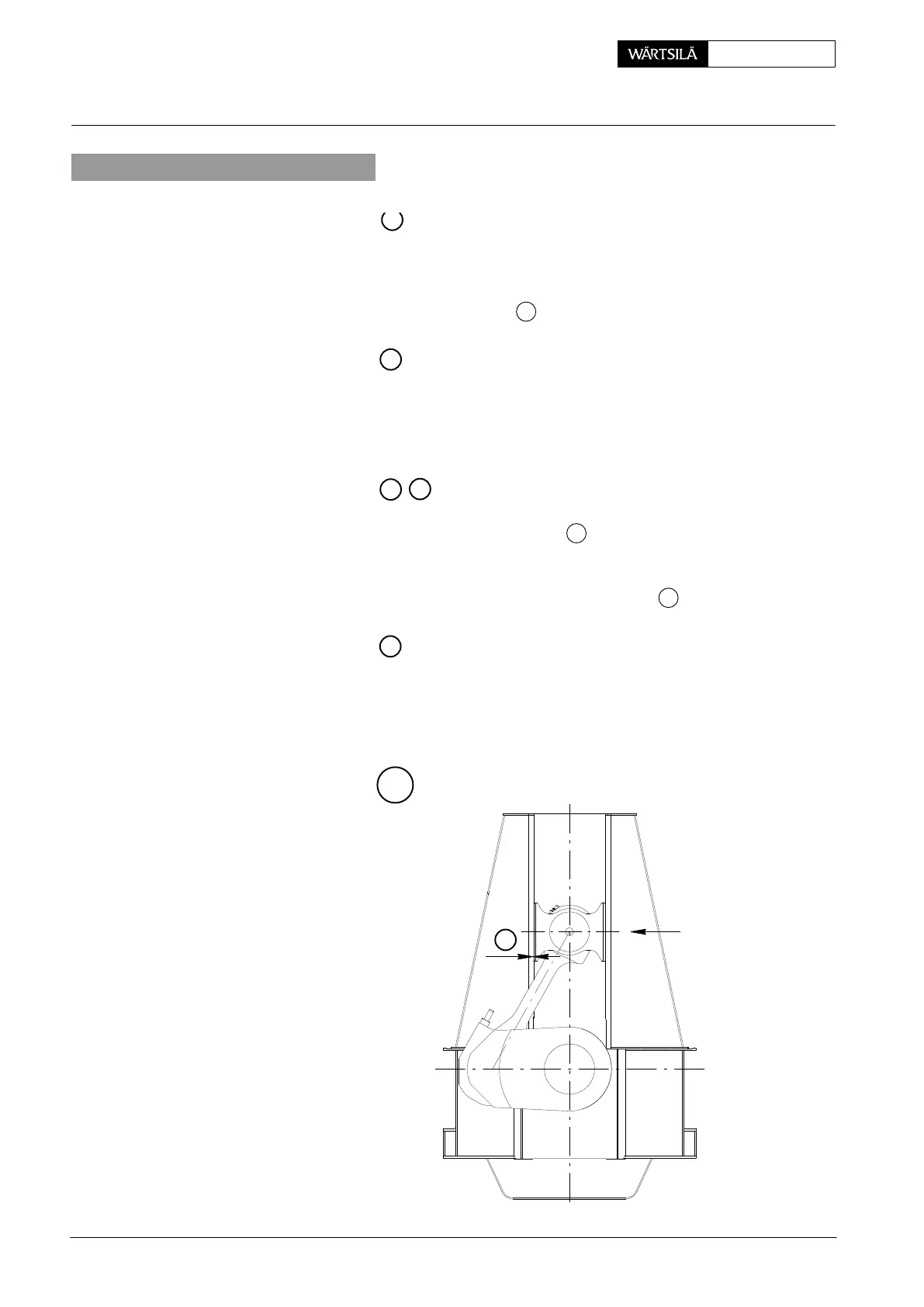

Clearance Clearance between guide shoe and guide way:

The corresponding crankpin must stand in such a positio

that guide shoes 2 lie on guide ways 4 on fuel or exhau

side.

Clearance is valid for the whole guide way length and

measured according to the positions as shown in Fig. ’B

Clearance Lateral clearance of crosshead between the column

The clearance is measured in every position of the cros

head. The complete crosshead must be pressed axially

a side with suitable hardwood wedges or similar aids. Th

pressure must be exerted onto the guide shoe and no

onto the crosshead pin 1.

Clearances Lateral clearance between guide shoe and

top end bearing:

Lateral clearance (between holding plate and groove

crosshead pin) is measured in the above mentioned pos

tion of the crosshead.

Measure total lateral clearance between top end

bearing 5 and guide shoes 2 at the same time.

Clearance Radial clearance between guide shoe and

crosshead pin:

The clearance is measured in every position of the cros

head.

2

3

4

5

1

3

4

B

1

013.784/06

90° BEFORE OR

AFTER T.D.C.

Checking the Clearances and Fitting the Guide Shoes

2010

Loading...

Loading...