Maintenance

5562−2/A1

RT-flex50-D

Wärtsilä Switzerland Ltd

1/ 2

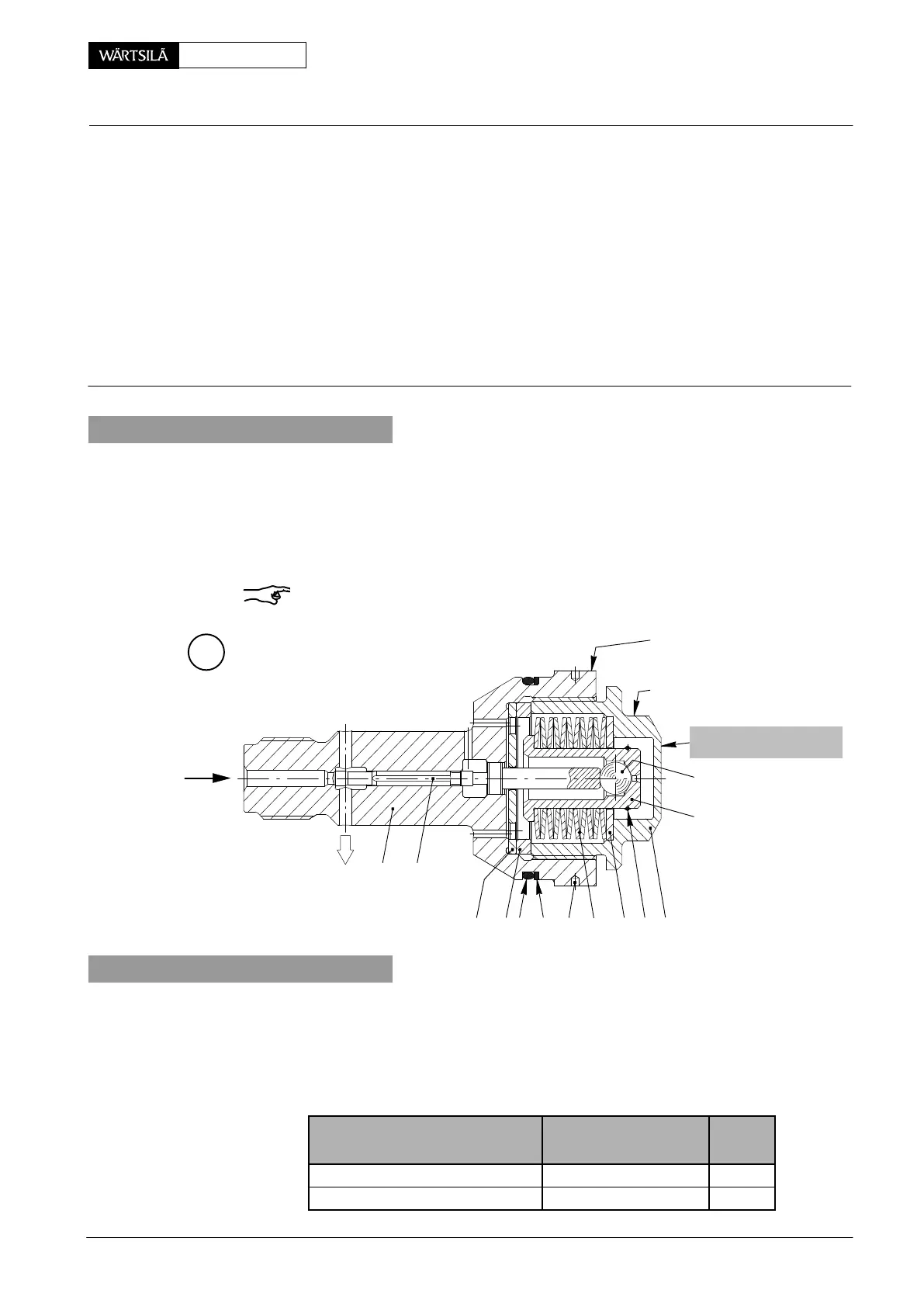

Tools: Key to Illustrations:

1 OBEL test bench 94272 1 Valve housing 11 Fuel overpressure

1 Valve holder 94272a 2 Valve needle safety valve 3.52

1 HP oil pump 94931 3 Ball 12 Receiver

2 Hydr. distributors 94934a 4 Spring carrier 13 Back-up ring

2 HP hoses 94935 5 Disc spring (11 pieces) 14 O-ring

6 Stop ring

7 Distance ring

8 Seating washer AB Drain bore

9 Snap ring EV Relief valve

10 Screw plug MK Marking ∅3 mm

1. General

A relief valve normally requires no maintenance, however the opening pressure

and the tightness should be checked according to Maintenance Schedule 0380−1.

Leaky or faulty valves have to be returned to the manufacturer or to a Wärtsilä

Switzerland Ltd. authorized repair workshop for inspection and repair.

The opening pressure of the relief valve must be approved by IACS (International

Association of Classification Societies) and recorded on the Inspection Report.

Remark: To identify the new fuel overpressure safety valve (relief valve) 11, two

bores ’MK’ on one face have been provided as a marking.

A

015.499/07

AB

3

4

12

OPENING PRESSURE

STAMPED IN

AF41

AF80

2. Checking

In order to properly loosen the relief valve from the fuel accumulator, a spanner

AF80 must be used and placed on housing 1!

Test bench 94272 as well as test & calibration fluid has to be used (e.g. Shell Cal-

ibration Fluid S.9365) complying with the data according to the following table:

2.1 Physical characteristics for test & calibration fluid

Kinematic Viscosity ASTM D445

at 40 _C

mm

2

/s 2.6

Density at 15 _C

kg/m

3

ISO 12185 827

Pour Point

_C

ISO 3016 −27

uel Overpressure Safety Valve

hecking and Setting

2010

Loading...

Loading...