Maintenance

8447−1/A1

RT-flex50-D

Wärtsilä Switzerland Ltd

3/ 4

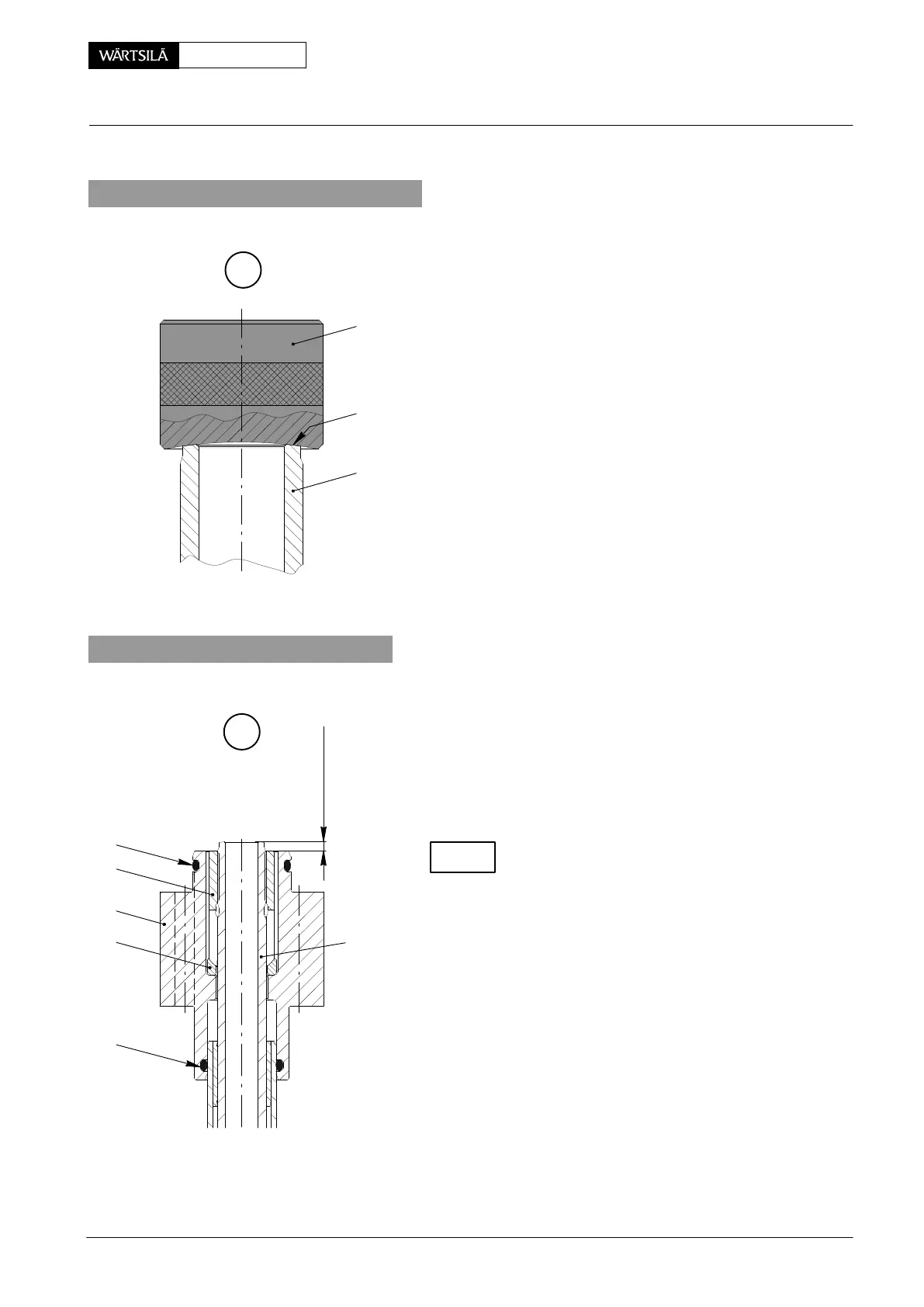

3. Regrinding the sealing faces ’DF’

D

013.459/05

94834

DF

2, 3

⇒ Loosen claw 9 (Fig. ’E’).

⇒ To prevent grinding compound from entering th

servo oil piping, plug its opening with a piece

cloth.

⇒ Use device 94834 for regrinding sealing face ’DF

⇒ First rough-grind the sealing face with grinding com

pound No. 200, then finish-grind it with grindin

compound No. 500.

⇒ After grinding thoroughly clean the servo oil pipin

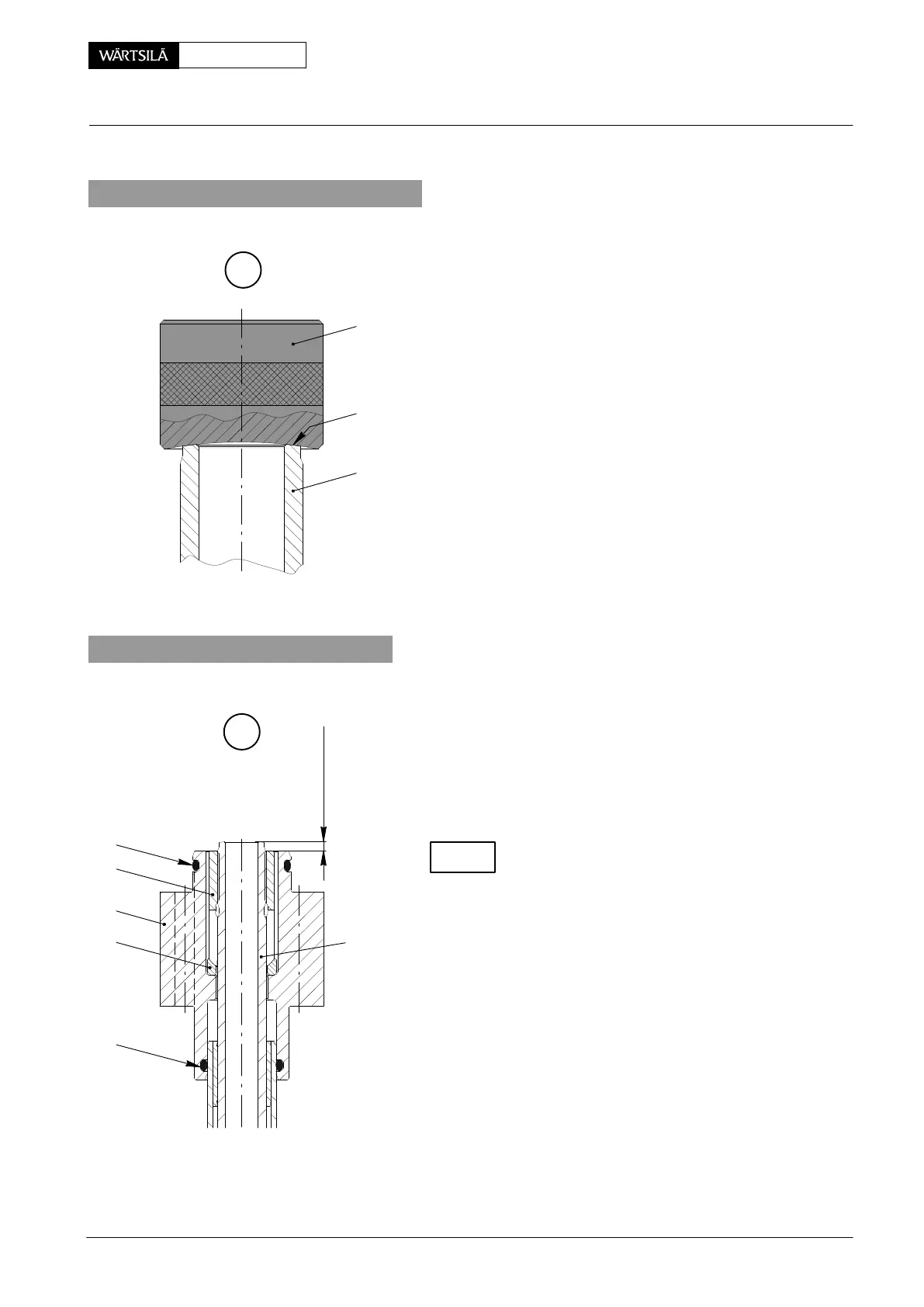

4. Adjusting the claws

Before fitting the servo oil piping check whether i

claws 9 are screwed on properly (Fig. ’E’), i.e. th

servo oil piping must protrude by ’x’ = 5.5 m

compared to the claw.

Measure ’x’ can be adjusted by turning the claw u

ing an open-end wrench.

CHECK

E

x = 5.5 mm

2, 3

16

9

5

10

17

013.520/05

2010

ervo Oil Piping: Removing, Fitting and Regrinding

Loading...

Loading...