Maintenance

3403−1/A1

RT-flex50-D

Wärtsilä Switzerland Ltd

3/ 8

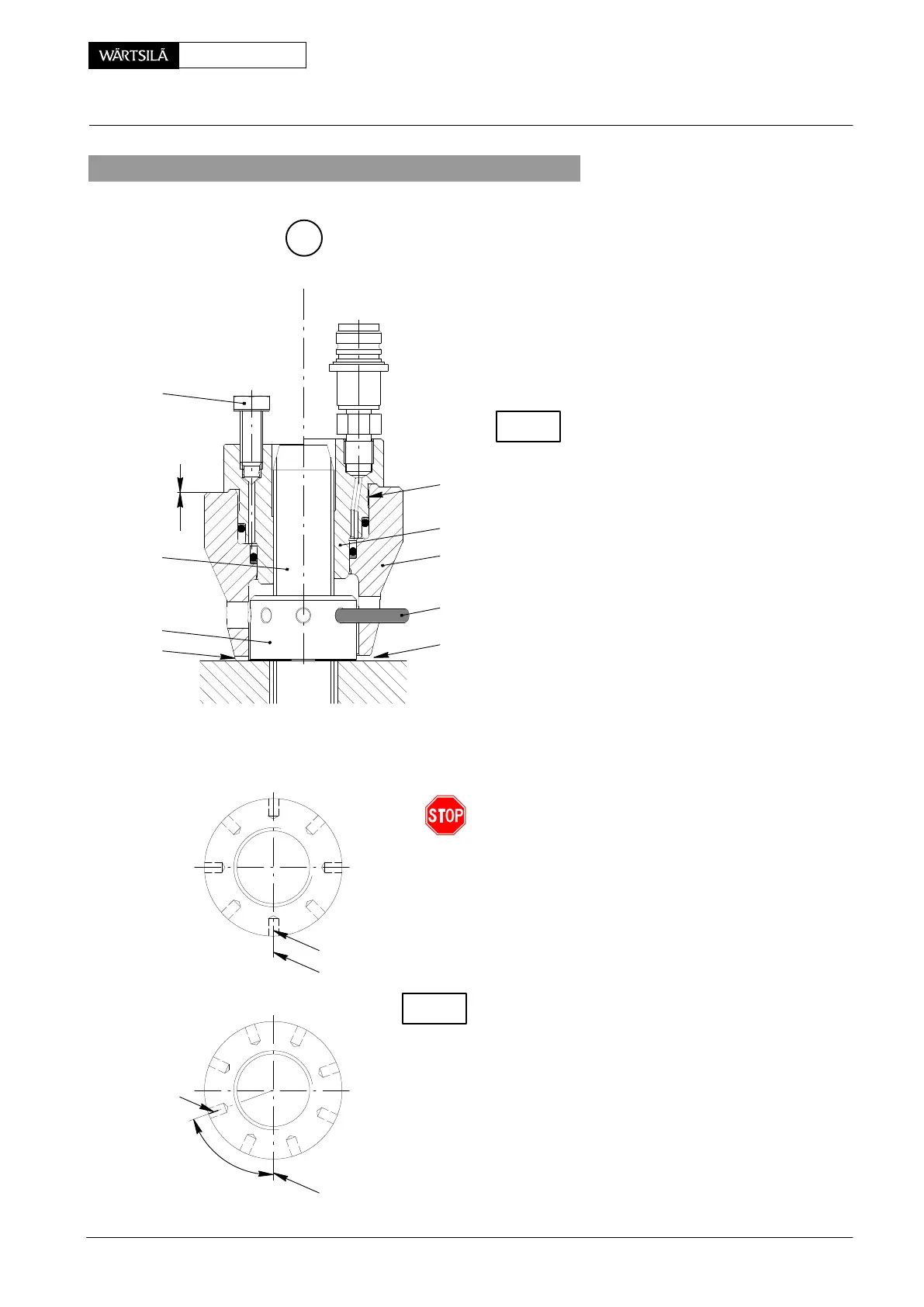

3. Tensioning the waisted studs of piston foot fastening

⇒ Clean the threads of waisted studs

and the area around nuts 4.

⇒ Apply oil to the threads of the waiste

studs and screw on the nuts.

⇒ Tighten the nuts with round bar ’RS

by hand.

Using a feeler gauge, check whether th

nuts rest without clearance.

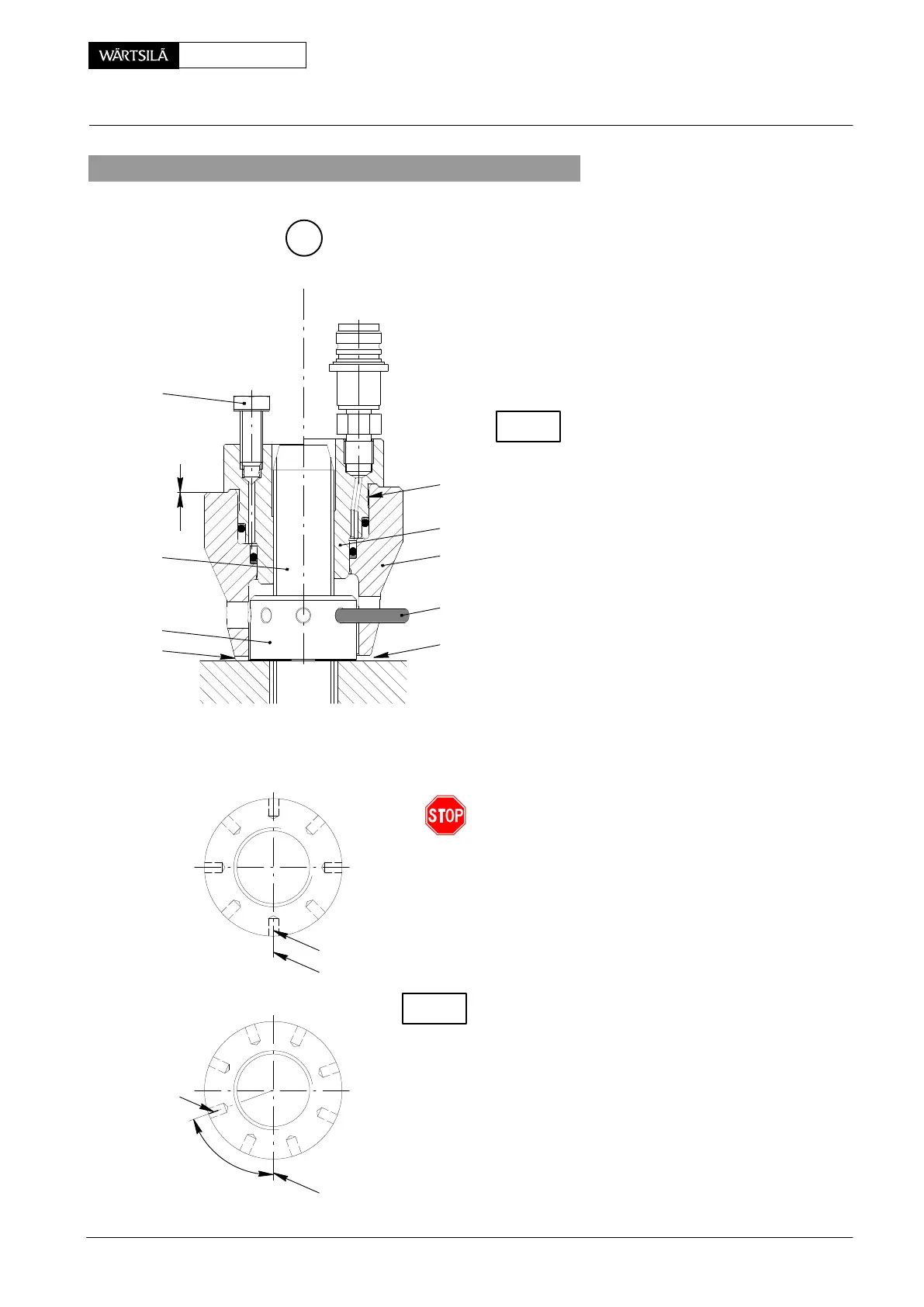

⇒ Mark position of nuts to seating su

face with a felt tipped pen (Fig. ’a’)

⇒ Completely screw the pre-tensionin

jacks diagonally onto waisted studs

(Fig. ’A’). Moreover, vent screws

are to be opened slightly so that pis

tons 7 can slide back to their initi

position i.e. there is no or very litt

clearance at ’x’ (Fig. ’B’).

⇒ Connect both pre-tensioning jacks

HP oil pump 94931 as shown in Fig

’A’.

⇒ Shut relief valve ’EV’ and start up HP oil pum

94931 till bubble-free oil flows out through ven

screws 5. Shut the vent screws.

⇒ Slowly raise the pressure to 1500 bar.

Pistons 7 of the pre-tensioning jacks must never excee

the red limiting grooves ’BN’ (Fig. ’B’).

⇒ Keep the pressure of 1500 bar constant and tighte

nuts 4 with round bar ’RS’ till firmly seated.

⇒ Release pressure to zero with the aid of relief valv

’EV’ at the HP oil pump and then screw the pre-ten

sioning jacks onto the other two waisted stud

These are to be tensioned in the same sequence a

described above.

After tensioning the nuts check their seatings with

feeler gauge through slot ’KO’.

After tensioning the nuts check again if these have bee

turned by about the same angle i.e. about 80_

compared with the marks previously made (Fig. ’b’).

CHECK

CHECK

B

x

Fig. ’a’

y

Fig. ’b’

y

009.752/02

x

010.031/02

PRE-TENSIONING JACK PLACED FOR

TENSIONING LOOSENING

TIGHTENING ANGLE

SA

x

8

RS

7

BN

013.254/05

3

4

KO

5

2010

Piston: Removal and Fitting

Loading...

Loading...