Maintenance

2708−3/A1

RT-flex50-D

Wärtsilä Switzerland Ltd

1/ 1

Tools: Key to Illustrations:

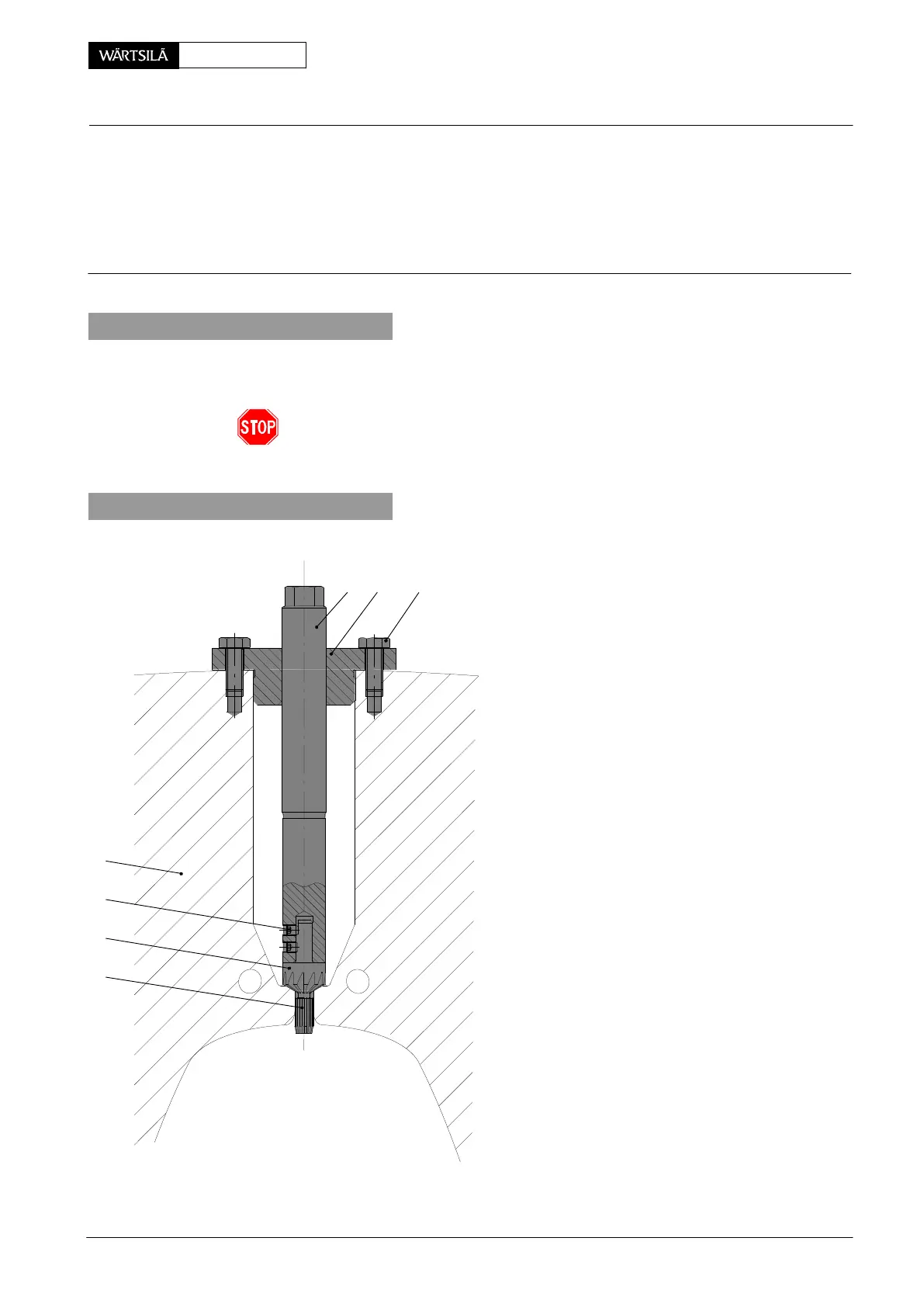

1 Overhauling device 94270 1 Cylinder cover 5 Profiling cutter

2 Milling cutter holder 6 Centring mandril

3 Guide flange 7 Screw

4 Setscrews

1. General

The seat sealing face in the cylinder cover must be clean and undamaged as the

sealing is metallic.

Should any blow-by of combustion gases have been noticed during engine opera-

tion, the spring packets with their screws of the injection valve are not, under any

circumstances, to be tightened further as a counter measure.

2. Machining of sealing face

Dirty or slightly damaged sealing faces can be r

conditioned on the spot by using overhauling d

vice 94270.

⇒ Carefully insert the profiling cutter, bolted

the milling cutter holder, into the hole in th

cylinder cover.

⇒ Fasten guide flange 3 with screws 7.

When the tool is being used, the centrin

mandril on the profiling cutter on the on

hand and the guide flange on the other, giv

the tool the necessary stability and directio

⇒ Cutting is done by pressing down lightly wi

the hand on the milling cutter holder at th

same time as turning the hexagon even

with the other hand using the ring spanner

Try to remove as little material as possible b

sufficient, however, to obtain the desire

standard for the seating area.

D Putting some sticky grease on the profilin

cutter will prevent any foreign matter from e

tering the combustion chamber during ove

haul.

012.903/05

1

4

5

6

2

3 7

ylinder Cover

achining of Sealing Face for Injection Valve

2010

Loading...

Loading...