Maintenance

8752−1/A1

RT-flex50-D

Wärtsilä Switzerland Ltd

1/ 5

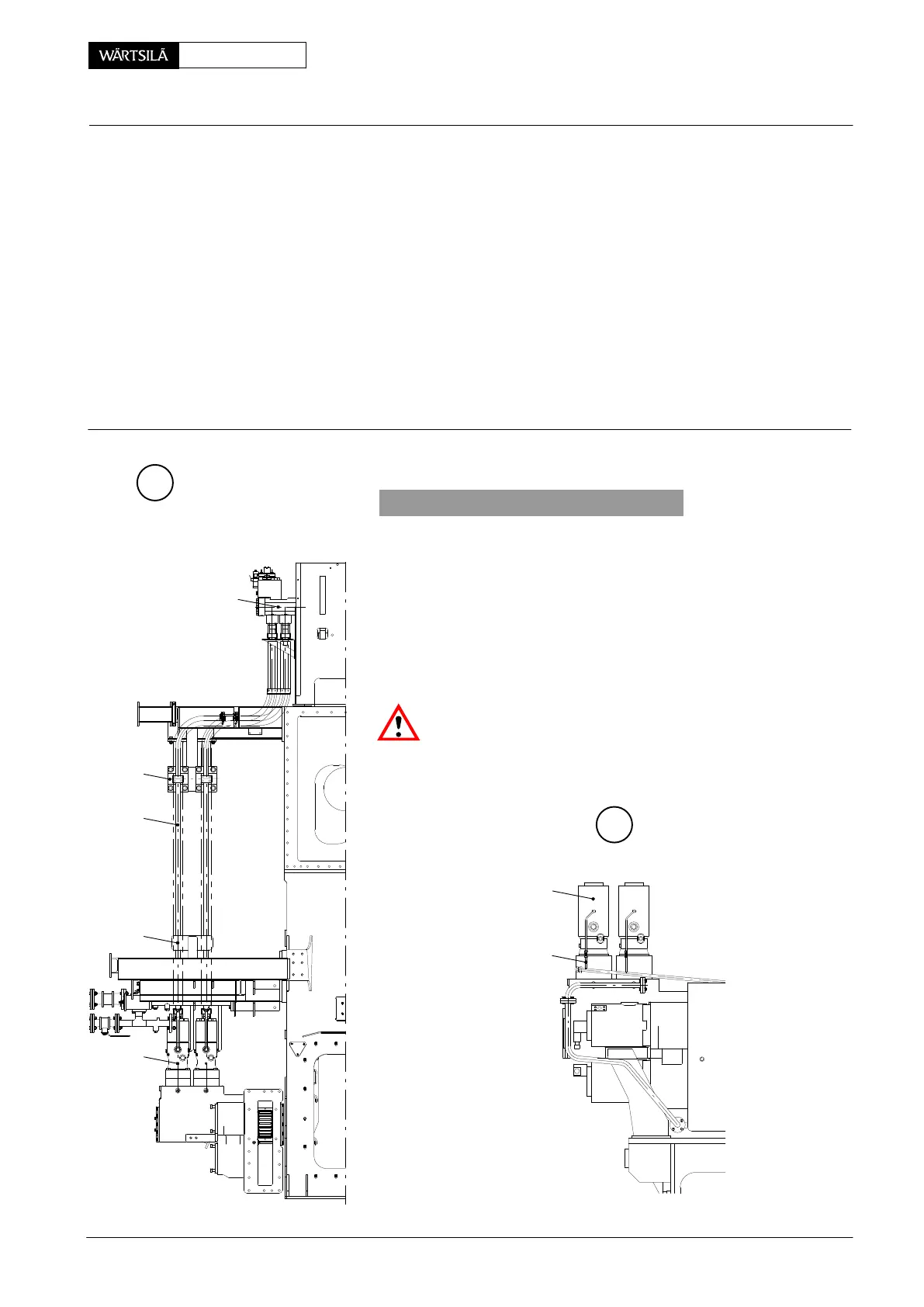

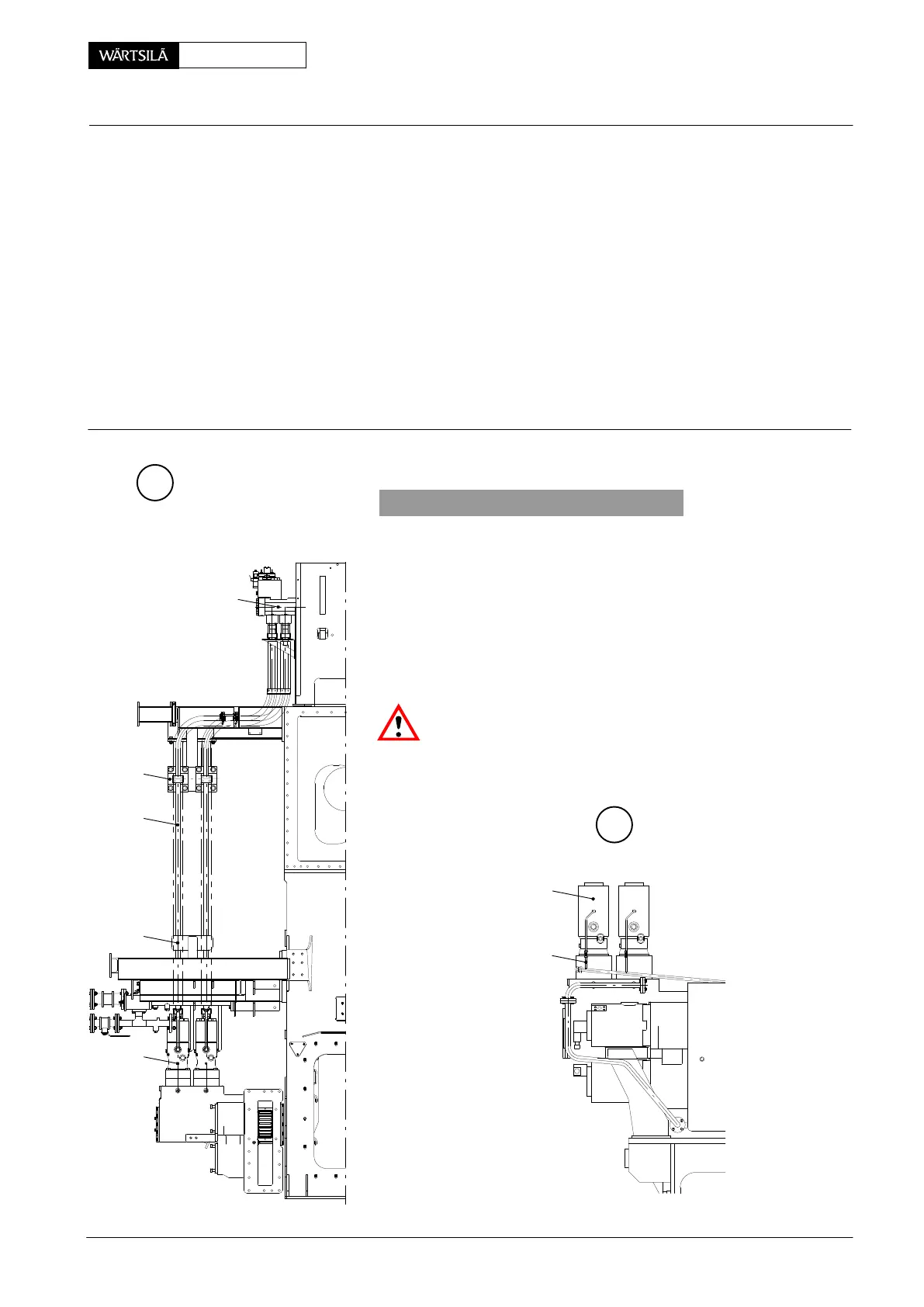

Tools: Key to Illustrations:

1 Regrinding device 94870 1 Fuel pressure piping 13 Pressure spring

consisting of: 2 Fuel pump 14 Non-return valve

1 Screw-on sleeve 94870e 3 Fuel rail 15 Claw

1 Grinding tool 94870f 4 Screw 16 Thrust ring

1 Lock nut 94870g 5 Mounting clamp 17, 17a Holder

1 Template 94870h 6 Screw 18 Leakage fuel pipe

7 Screw 19, 20 O-ring

1 Torque wrench 8, 8a Flange

9 Fuel pump cover DF Sealing face

10 Intermediate ring EC Emery cloth

11 Valve housing HD Hand drill

12 Lip seal LB Leakage fuel bore

A

019.070/09

2

1. General

The engine must be stopped, the fuel supply pump switched o

and then the fuel pressure pipings can be drained via bores ’L

(section III-III) and leakage fuel pipes 18.

D For that screws 7 must be loosened, flange 8a and inte

mediate ring 10 (section I-I), as well as screws 6 an

flange 8 at fuel pump cover 9 pushed back in order to se

arate fuel pressure piping from its sealing faces.

Non-return valves 14 prevents the fuel rail from discharging

Risk of accident! Make sure that the steam supply is close

before loosening the screwed connections to the heating pipe

1

3

B

016.520/08

18

2

17a

17

uel Pressure Piping

emoving, Fitting and Regrinding 5 and 6 Cylinder Engine

5 & 6 Cyl. / 2010

Loading...

Loading...