Maintenance

8752−1/A1

RT-flex50-D

Wärtsilä Switzerland Ltd

5/ 5

G

H

I

016.739/08

016.739/08

016.739/08

1

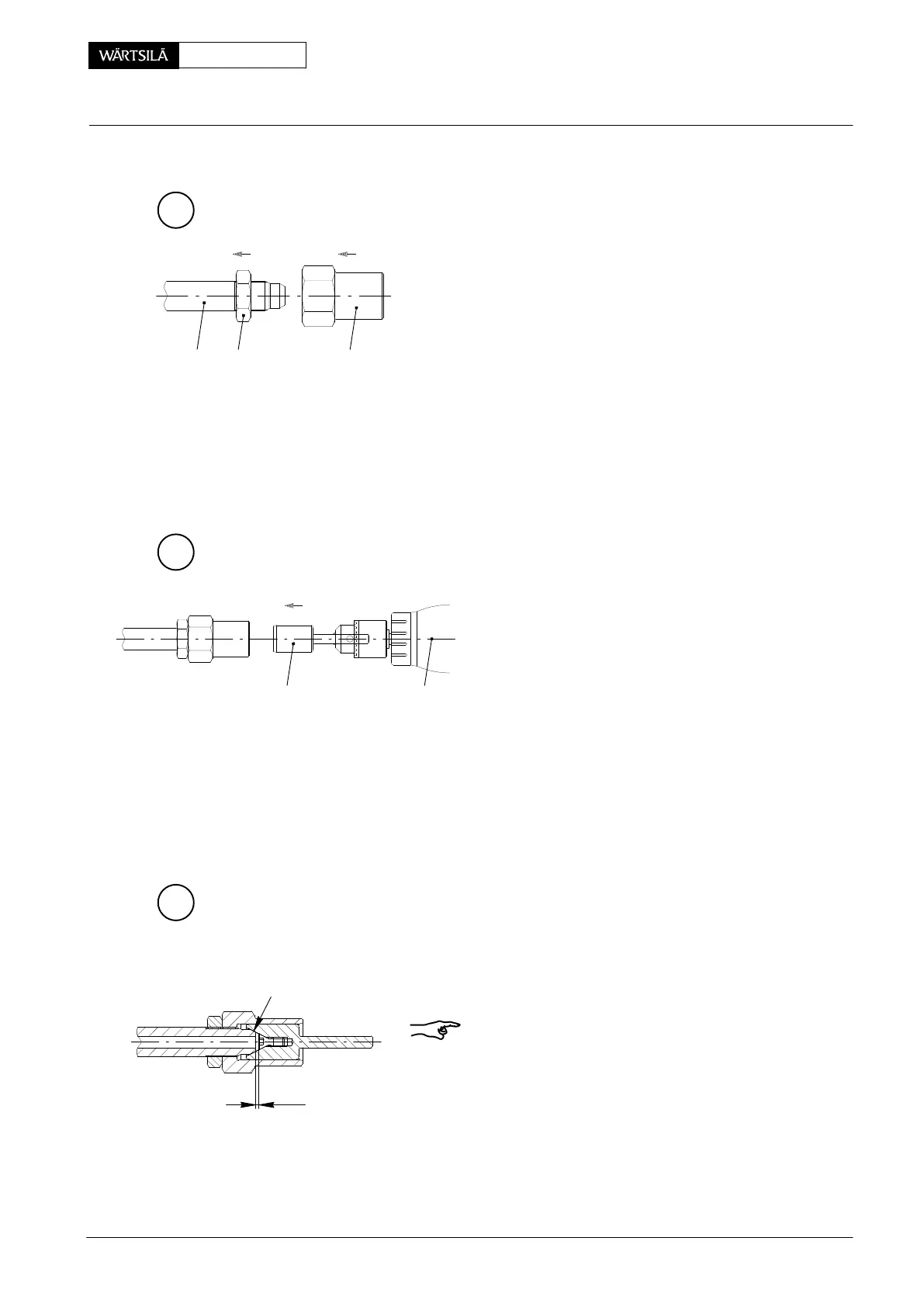

x

DF

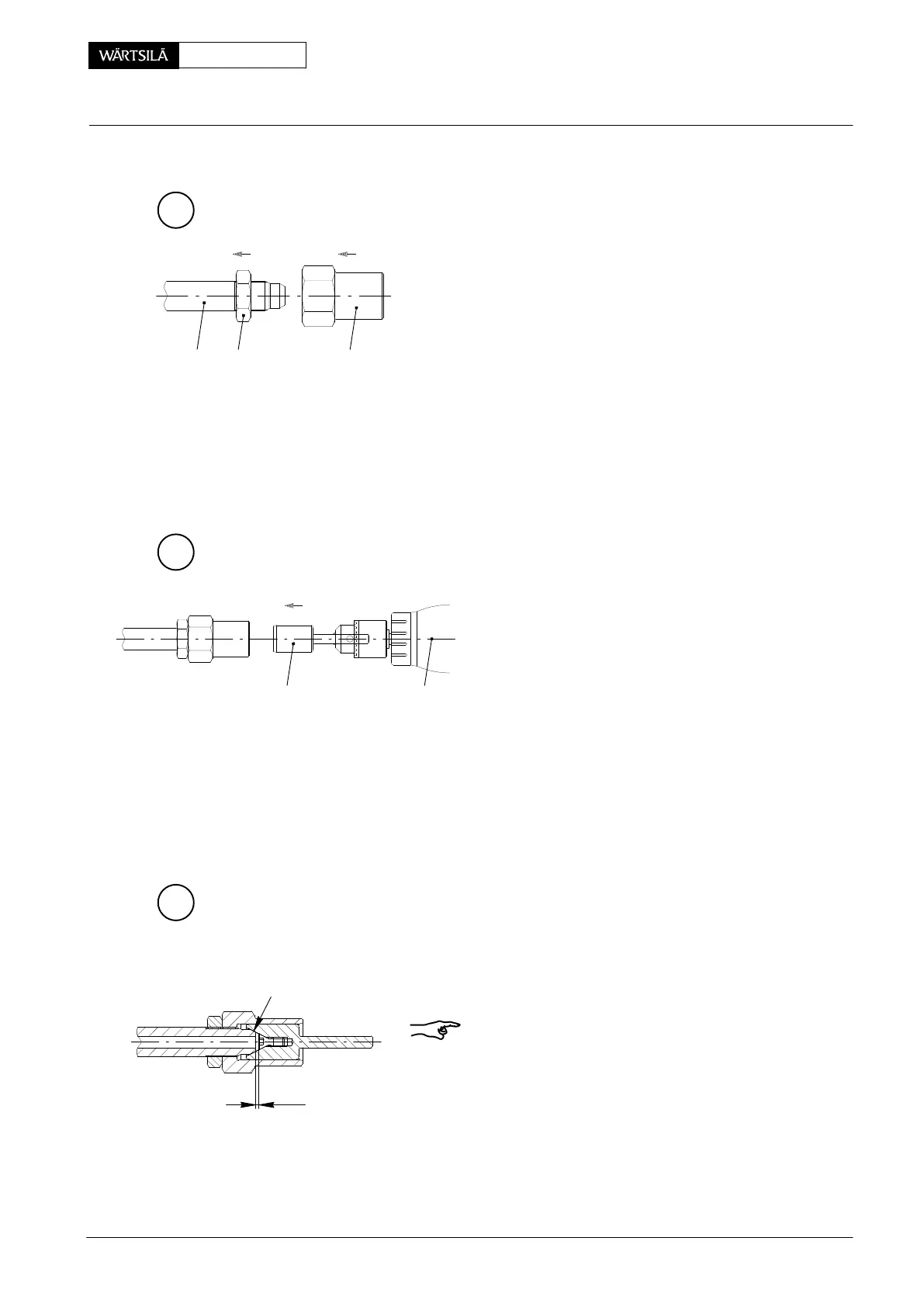

94870g 94870e

1. 2.

HD

94870f

⇒ Remove claw 15 (Fig. ’D’).

⇒ Fix fuel pressure piping 1, e.g. in a vice.

⇒ Screw on counter nut 94870g until it reaches th

thread end of the fuel pressure piping.

⇒ Turn screw-on sleeve 94870e up to the counter nu

⇒ Lock the screw-on sleeve with the counter nut.

⇒ Clamp grinding tool 94870f in hand drill ’HD

⇒ Slide grinding tool into the screw-on sleev

until it slightly touches the fuel pressu

piping.

⇒ Let the grinding tool rotate with a max. spee

of 1500 rpm and grind for 3 to 5 seconds.

⇒ Withdraw the grinding tool from the screw-on sleev

and blow out both parts with pressurized air.

⇒ Verify the surface quality of sealing face ’DF’ and

necessary repeat the regrinding process using

fresh emery cloth ’EC’.

Remark: In case of big notches the tube has to be shor

ened in order to restitute a clearance of ’x’ = min. 0.5 m

between the countersunk screw and the end face.

⇒ Remove counter nut and screw-on sleeve.

⇒ After grinding thoroughly clean the fuel pressu

piping.

uel Pressure Piping: Removing, Fitting and Regrinding 5 and 6 Cylinder Engine

2010

Loading...

Loading...