Maintenance2751−1/A1 RT-flex50-D

Wärtsilä Switzerland Ltd

4/ 7

2. Fitting

⇒ Clean all the joint faces on the exhaust valve and in the cylinder cover and

check them for damages.

⇒ Clean the soft iron ring of 2 mm thickness, replace it if necessary, then put it in

the cylinder cover.

⇒ Fit new O-rings in the valve cage and valve seat and oil them slightly.

⇒ Fit the complete exhaust valve suspended on RUD-eye bolt ’RC’, taking care

not to damage the threads of the waisted studs (Fig. ’E’).

D The correct position of the exhaust valve cage is determined by the cylindrical

pin set in the cylinder cover.

⇒ Smear thread of waisted stud lightly with oil.

⇒ Fit nuts 2 and tighten them firmly with round bar ’RS’.

Check seating of nuts 2 with a feeler gauge.

⇒ Mark position of nuts on a corner and their position on valve cage 7 with a felt-

tip pen (for later checks).

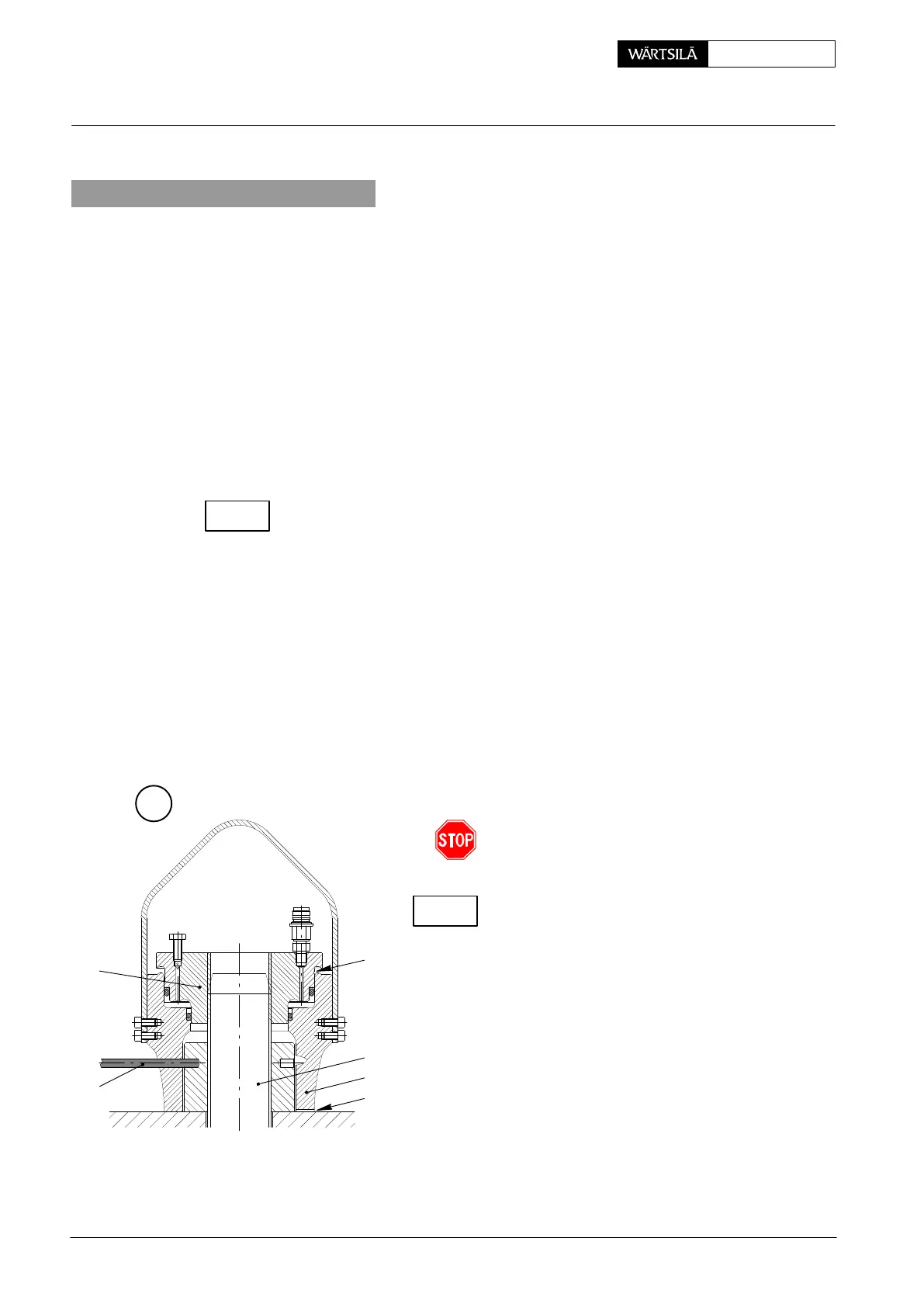

2.1 Tensioning of waisted studs

⇒ Screw pre-tensioning jacks 94252 onto waisted studs 1 as mentioned in para-

graph 1.1, however, do not turn back them.

⇒ Connect pre-tensioning jacks to hydraulic unit 94942 and actuate the latter.

⇒ Close vent screws 3 on the pre-tensioning jacks as soon as oil flows bubble-

free.

⇒ Slowly raise the pressure to 1500 bar.

Pistons 4 of the pre-tensioning jacks must never e

ceed the red limiting grooves ’BN’ (Fig. ’G’).

⇒ Tighten nuts 2 with round bar ’RS’.

Check seating of nuts 2 with a feeler gauge throug

slot ’KO’.

After tightening the nuts ascertain that these hav

been turned by about the same angle of 155_.

⇒ Release pressure to ’0’ and remove both pr

tensioning jacks.

CHECK

G

BN

1

KO

2

4

RS

2010

Removal and Fitting of Exhaust Valve, Replacing of Waisted Studs

CHECK

Loading...

Loading...