Maintenance

1112−1/A1

RT-flex50-D

Wärtsilä Switzerland Ltd

3/ 3

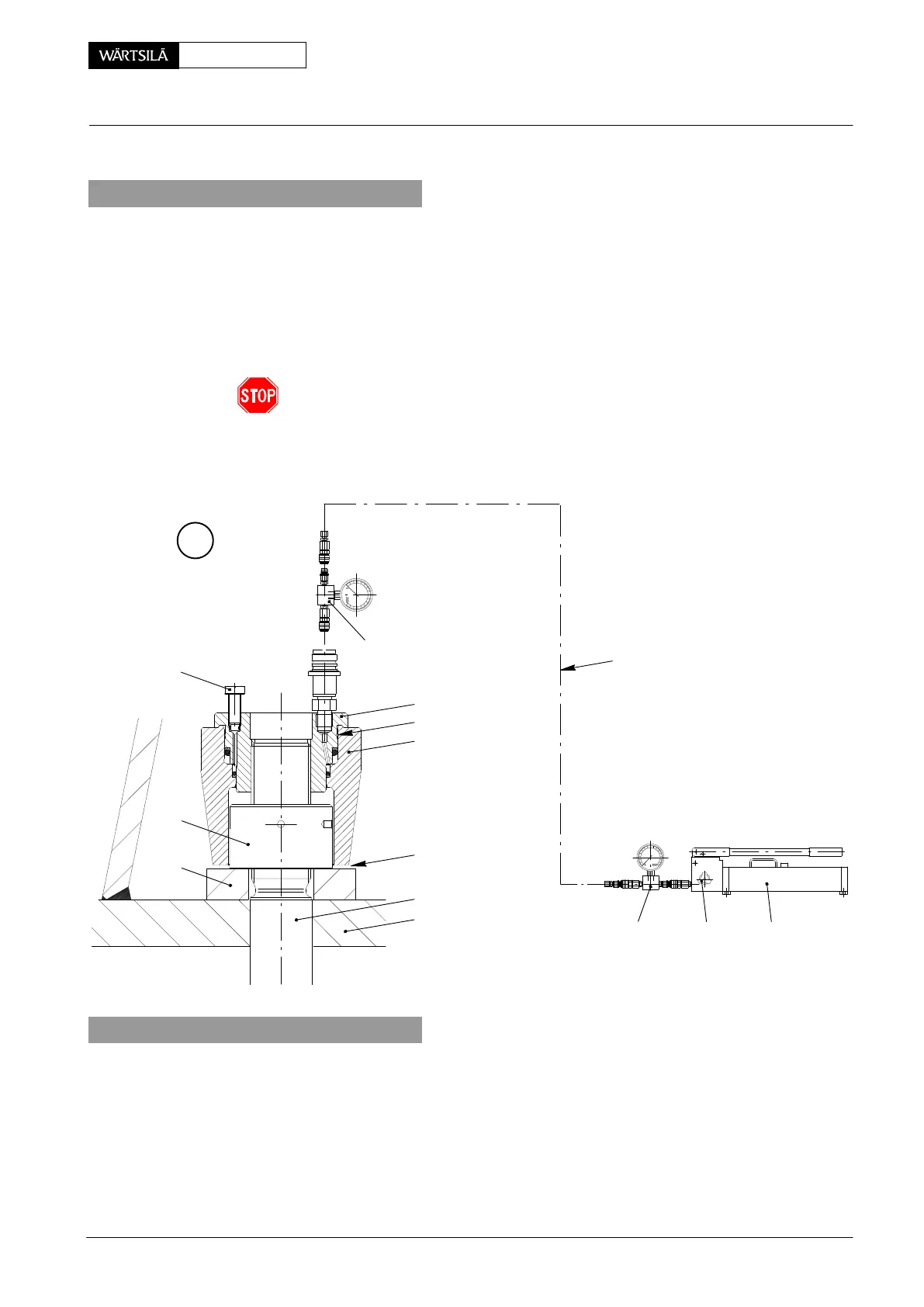

3. Loosening the foundation bolts

⇒ First screw down pre-tensioning jack 94145 as for checking the pre-tension,

then turn back by ½ turn (gap ’SA’ in Fig. ’E’).

⇒ Connect the pre-tensioning jack to HP oil pump 94931 according to Fig. ’E’.

⇒ Shut relief valve ’EV’ and actuate HP oil pump till oil flows bubble-free at vent

screw 1.

⇒ Close vent screw and pump until a pressure of 1530 bar has been reached.

Piston 3 of the pre-tensioning jack must never exceed the red limiting groove ’BN’

(Fig. ’E’).

⇒ Turn back nut 4 by one turn, release the pressure to ’0’ and remove the pre-

tensioning jack.

E

012.950/0

94935

94934a

94931

EV

94934a

4

13

1

SA

6/7

3

5

BN

2

4. Tensioning the foundation bolts

D Tensioning of the foundation bolts must be carried out in two steps without ex-

ception, for both metal and synthetic chocks, i.e. tension all foundation bolts

first with 900 bar (1

st

step), then finish tensioning with 1500 bar (2

nd

step).

D Tensioning must be carried out as described in ’Checking the pre-tension’.

Checking the Foundation Bolts

2010

Loading...

Loading...