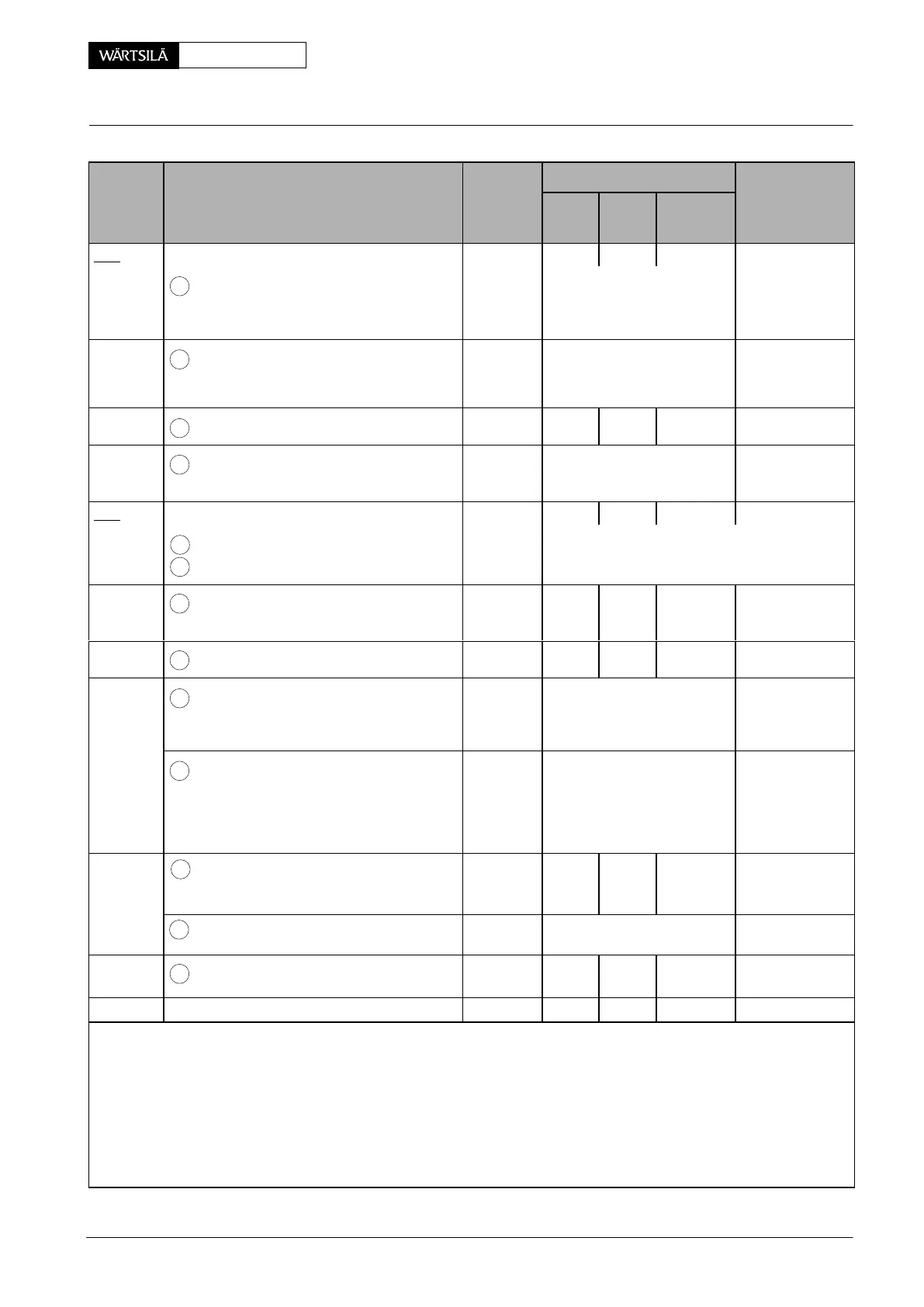

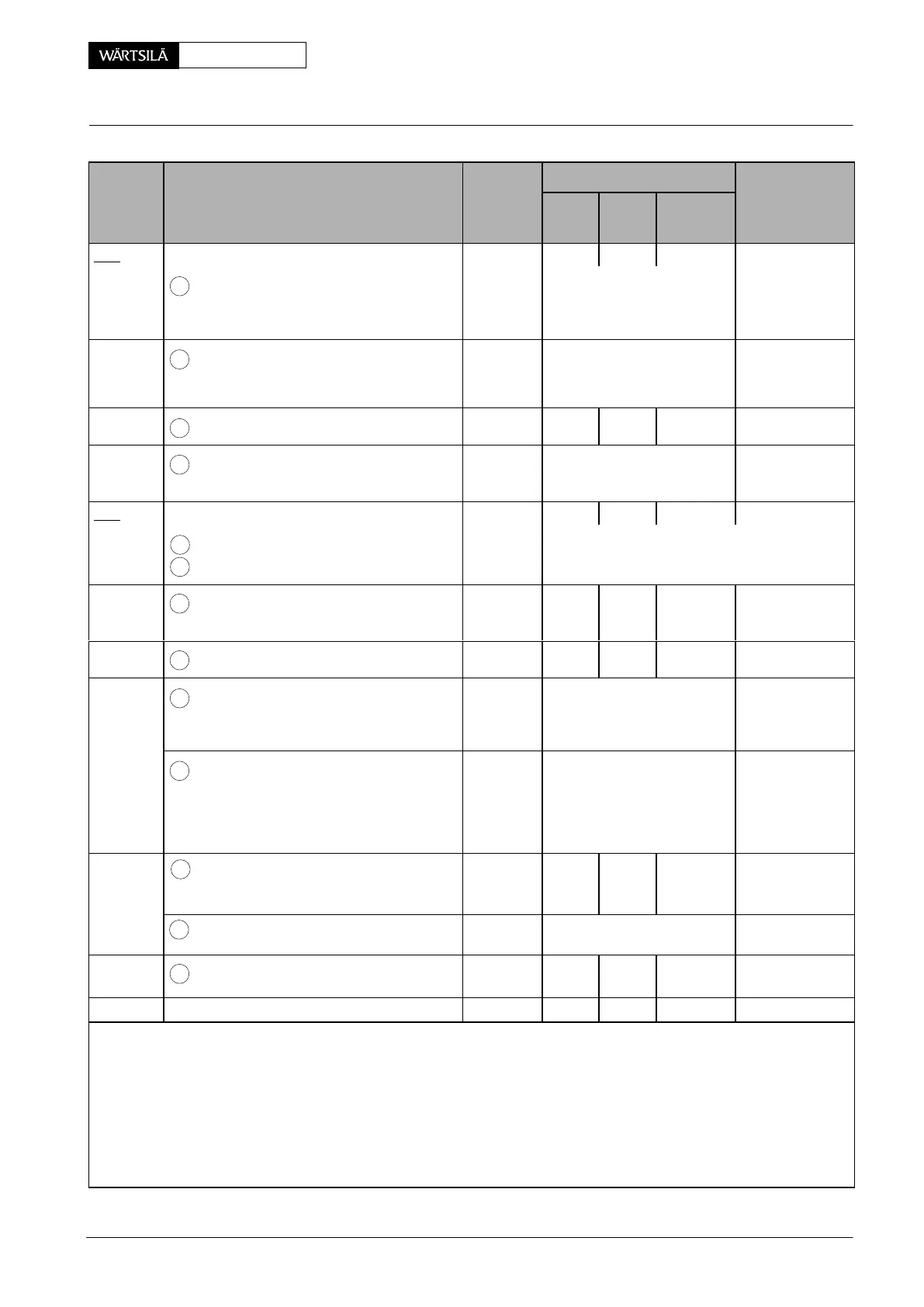

Maintenance

0352−1/A1

RT-flex50-D

Wärtsilä Switzerland Ltd

1/ 16

Group Description Thread Tightening values Lubricant

1

[bar]

2

[Nm]

3

[_(; mm]

1

1112−1

Foundation bolt

(metal and synthetic chocks)

1

M48 1500

1

st

step 900 bar

2

nd

step 1500 bar

MOLYKOTE G

1132−1

Main bearing, nut for waisted stud

2

M42

1

st

step 1000 Nm

2

nd

step 1500 Nm

1

st

step to 2

nd

step (20_)

Oil

1715−1

Engine stay (friction type)

3

M48 310

MOLYKOTE G

1903−1

Tie rod

(see instructions in 1903−1)

4

M72x6 1500

MOLYKOTE G

2

2106 *

*

Cylinder jacket bolting-up / bolt

Cylinder jacket bolting-up / fitted bolt

5

5

M36

M36

Elongation 0.50± 0.04 mm Oil

Elongation 0.30 ± 0.04 mm Oil

2138−1

Lubricating quill (Pulse Jet), screw

(see instructions in 2138−1)

6

M10x50 10

Oil

2708−2

Cylinder cover, nut for waisted stud

7

M56 1500

(255_)

Oil

2722−1

Injection valve, screwed connection

with cylinder cover

(see instructions in 2722−1)

8

M12 Equally tighten Allen

screws until spring guides

are flush with spring cages

Never-Seez

NSBT-8

Injection valve, retaining nut, nozzle

body − nozzle holder

9

M60x2

1

st

step 100 Nm

1

st

step to 2

nd

step 30_

Never-Seez

NSBT-8

(see instructions in 2722−1 with OBEL test

bench)

(loosen retaining nut after initial

assembly and then repeat tight-

ening procedure)

2728−1

Starting valve spindle, nut

(spindle thread not to be lubricated in region

of locking ring)

10

M20 140

MOLYKOTE G

Starting valve, screw

11

M20x150

1

st

step 80 Nm

1

st

step to 2

nd

step 90_

Never-Seez

NSBT-8

2745−1

Indicator valve, screw

12

M20 80

Never-Seez

NSBT-8

1 When using other hydraulic jacks, required pressure in bar must be calculated in relation to effective jack piston surface!

Conversion factor: 1 Nm = 0.102 mkp 1 bar = 1.02 kp/cm

2

2 Tightening torque

3 Tightening angle or elongation

− Numbers in

f refer to illustrations on pages 7 to 16.

− Values in parentheses (...) are for information only, to be used for comparison.

− Screwed connections must be tightened in accordance with values not in parentheses.

Respective lubricant has to be applied to threads and seating surfaces, if no other instructions are mentioned.

− Bostik Findley Inc. (USA) is manufacturer of Never-Seez NSBT-8.

* Tightening procedure not mentioned in this Manual.

50−D / 2011-12

ightening Values of Important Screwed Connections

Loading...

Loading...