Maintenance

4103−3/A1

RT-flex50-D

Wärtsilä Switzerland Ltd

5/ 5

The waisted studs are correctly pretensioned if an extension of nL 1.20± 0.06

mm is measured.

Check: There must be no gap in the gear wheel partition.

⇒ If the split pin for securing the castle nut cannot be fitted, turn the castle nut

only so far as to allow the split pin to be fitted.

⇒ After the check mentioned above has been carried out, dismantle both flange

screws 6 which have been temporarily fitted beforehand (Fig. ’H’).

Degrease the threads of all flange screws 6 and their self-locking nuts 8 and then

apply LOCTITE 262 to them; do not use MOLYKOTE!

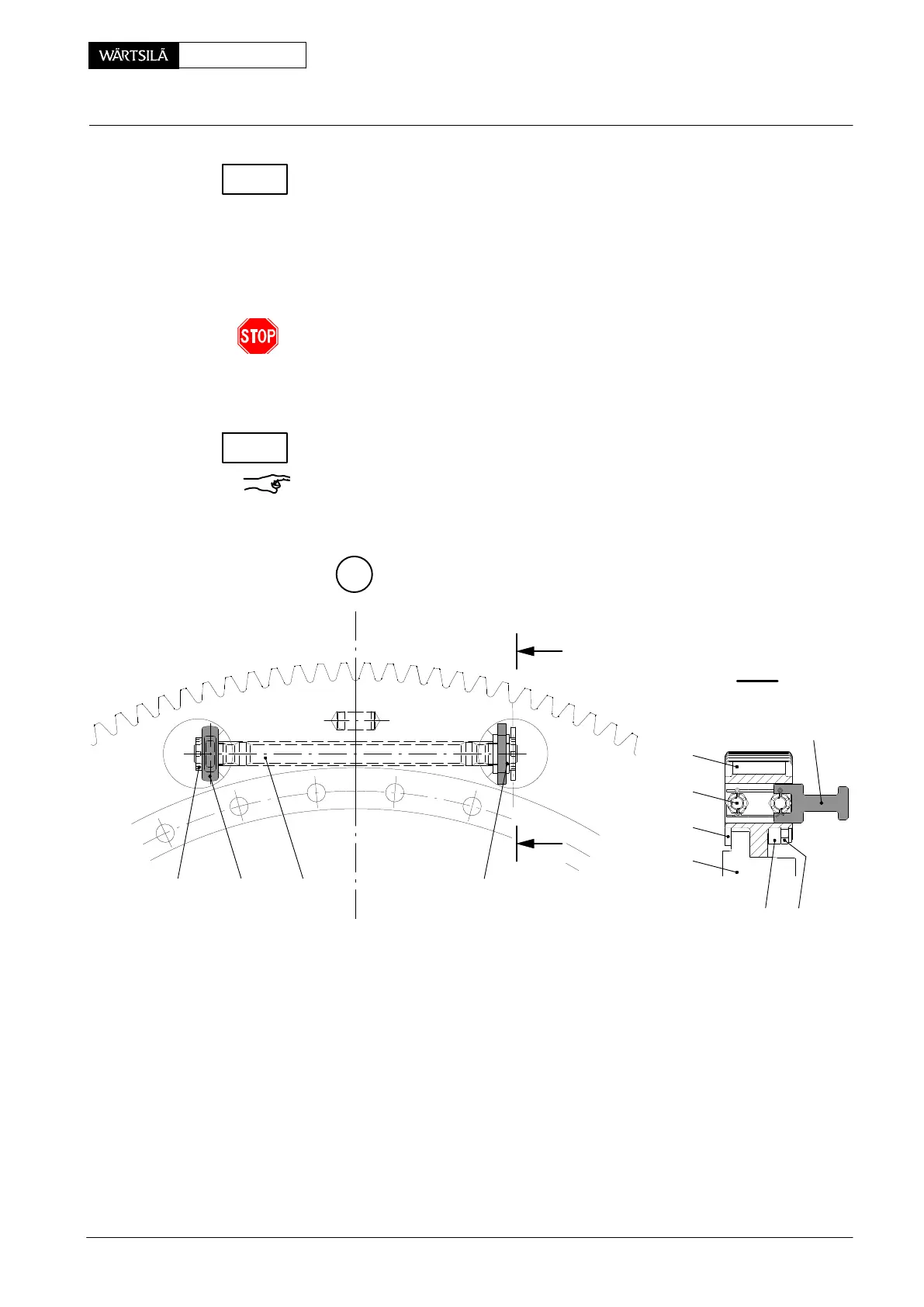

⇒ Fit all flange screws 6 with distance sleeves 7 and self-locking nuts 8 (Fig. ’I’).

Afterwards, tighten them crosswise and evenly distributed over the circumfer-

ence with an angle of twist of 70_ (800 Nm).

After assembling, check intermediate wheel as specified in 4103−1.

Remark: After fitting 2-part gear wheel, the running and backlash clearances and

performance of the teeth must be checked (see 4103−1).

I

MOLYKOTE

LOCTITE

262

013.640/0

I - I

1

6

78

94412

013.630/05

I

10 3

3/4

2

I

Replacing the Gear Wheel on the Crankshaft

2010

CHECK

CHECK

Loading...

Loading...