Maintenance

1132−2/A1

RT-flex50-D

Wärtsilä Switzerland Ltd

13/ 17

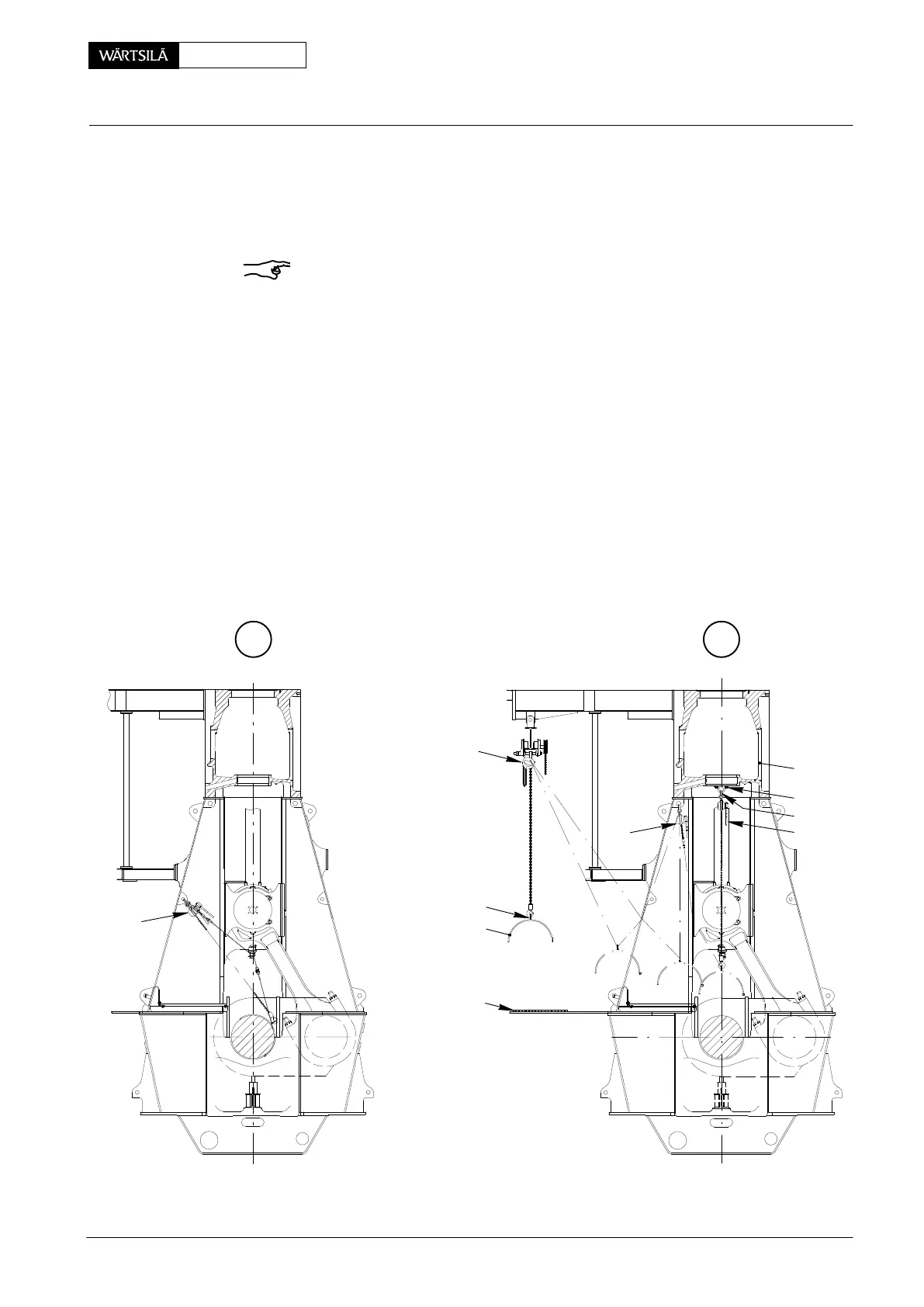

⇒ Remove assembling and dismantling device 94117, rope 94120a, device

94119b and turning-out device 94118a.

⇒ Fasten transportation tool 94116a to bearing shell 4a and turn it completely

out without major effort by means of manual ratchet H

1

.

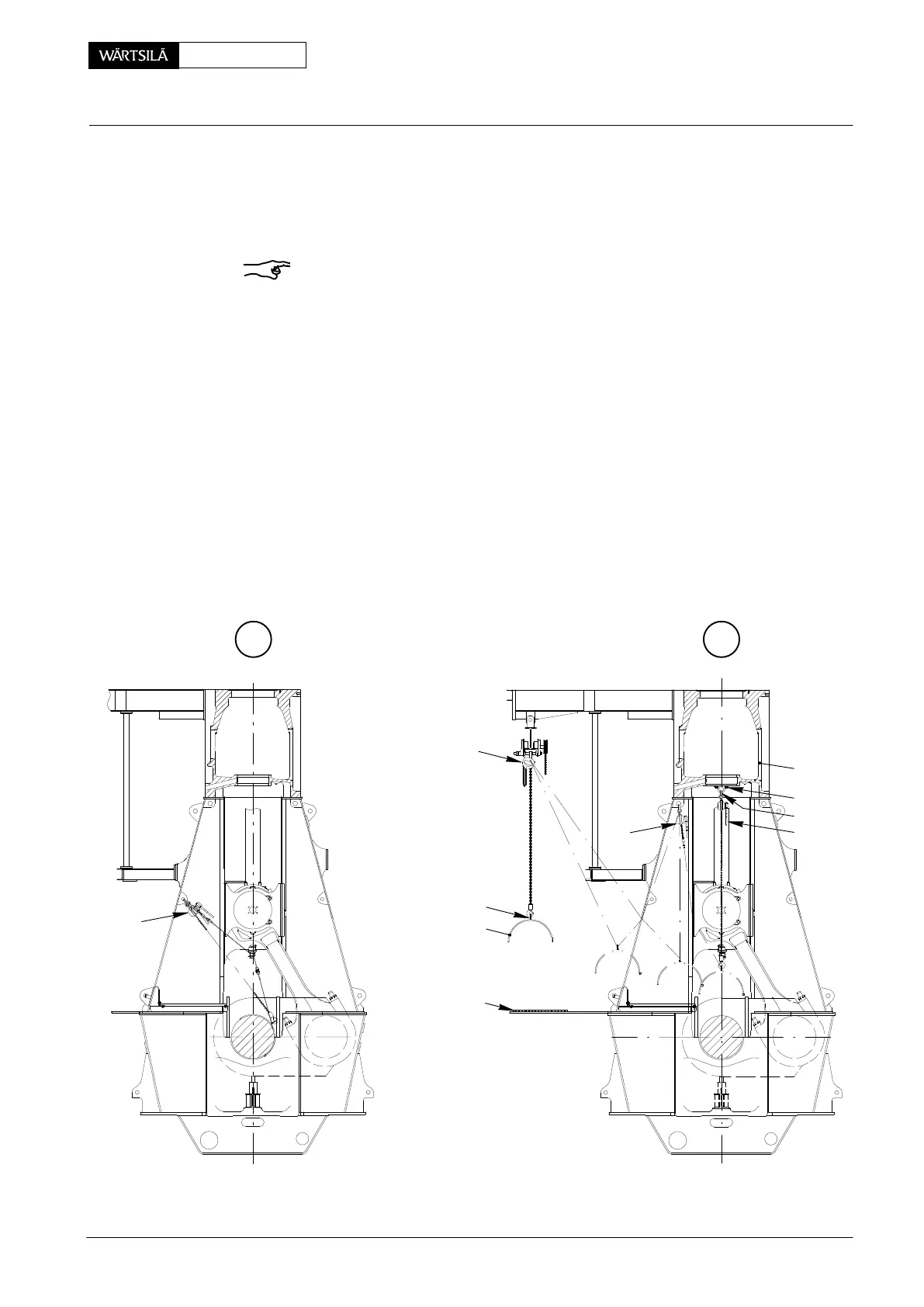

Remark: When retracted in upper position, both bearing shell ends are distinctly

uplifted from the bearing journal (see detail with gap ’x’ in Fig. ’J

2

’).

Also make sure that both ends of the bearing shell are cleared from the bearing

girder!

⇒ Fasten lifting ring 94332 (with shackle 94332a) to cylinder block 14 using

screws 15 which must be tightened with a torque of 200 Nm (see detail Fig.

’D’).

⇒ Connect manual ratchet H

2

to shackle 94332a and the transportation tool.

⇒ Carefully lift the bearing shell while guiding it manually, slacken manual ratch-

et H

2

and take over bearing shell with H

3

.

⇒ Detach manual ratchets H

1

and H

2

.

⇒ Remove the bearing shell from the crankcase using manual ratchet H

3

and

spur-geared chain block ’HZ’.

⇒ Place the bearing shell on wooden underlay ’HU’ on the bottom plate.

L

1

94332

H

1

L

2

018.609/09 018.613/09

H

2

H

3

HZ

94116a

4a

14

94332

HU

50−D / 2010

Removal and Fitting of a Main Bearing

Loading...

Loading...