Maintenance1224−1/A1 RT-flex50-D

Wärtsilä Switzerland Ltd

2/ 6

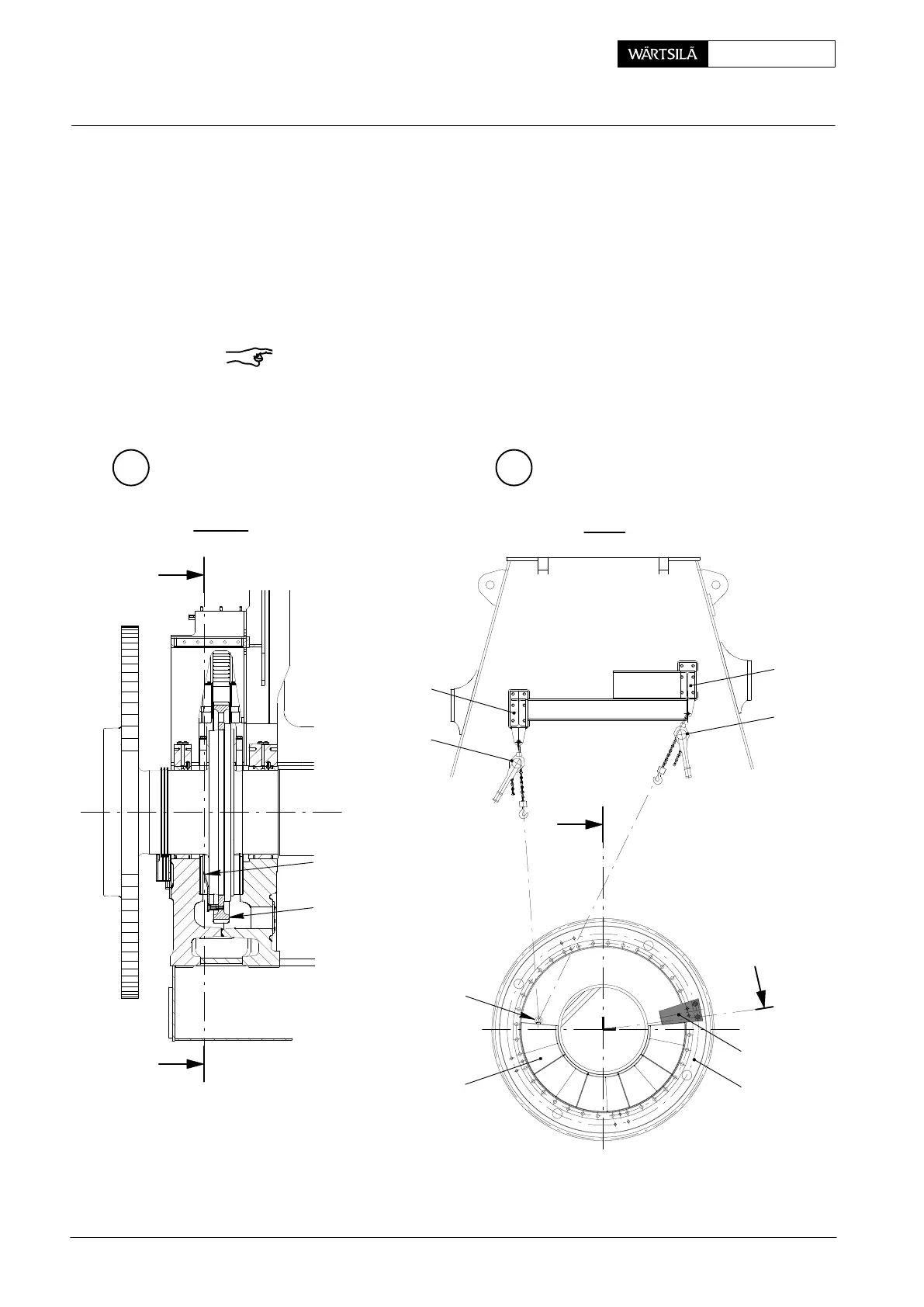

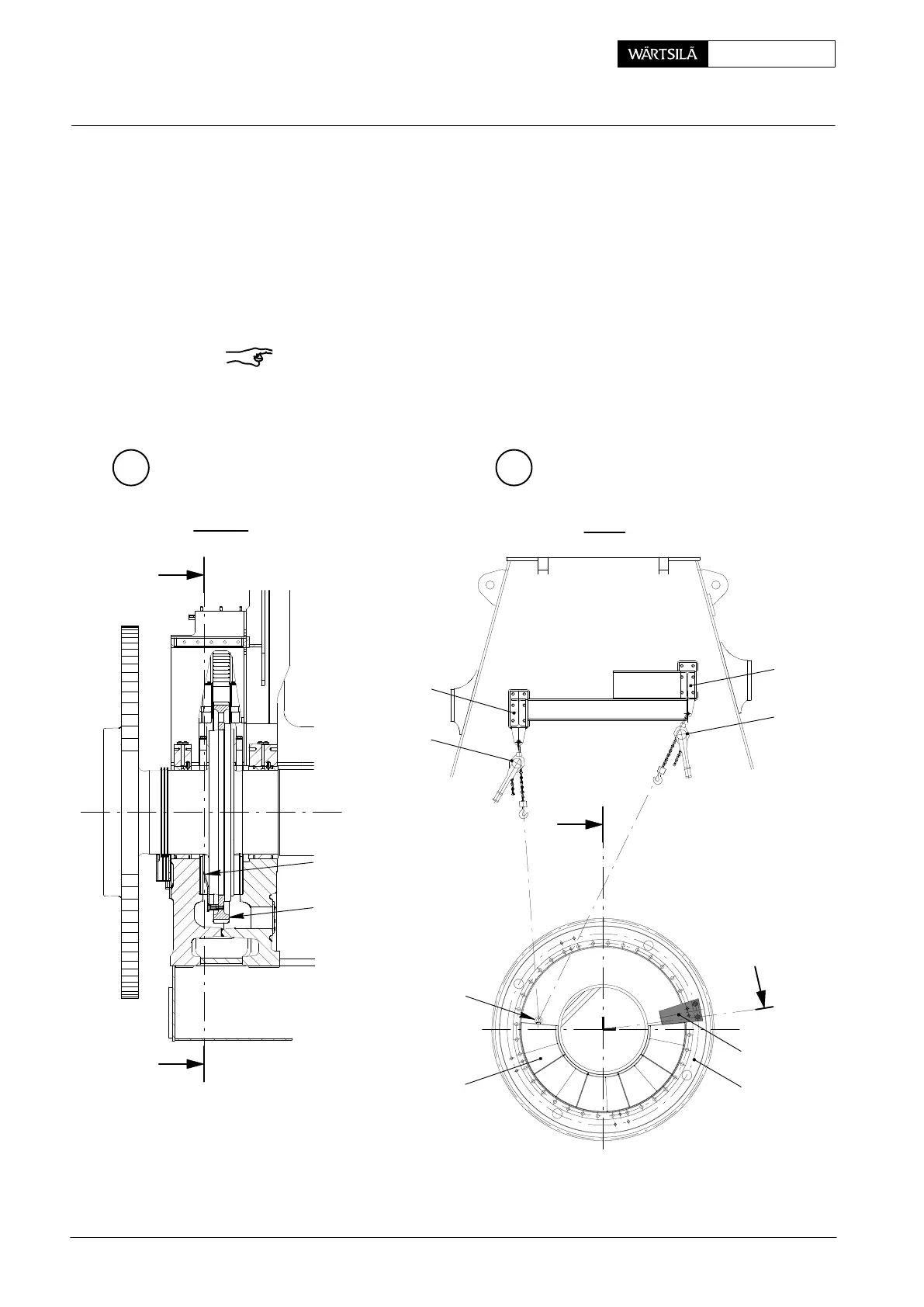

⇒ Screw RUD-eye bolt ’RC’ into thrust bearing pads 5 or 5a to be removed.

⇒ Fasten lifting tackles ’HZ’ to the straps of supports 7 and connect them with

ropes ’a’ and ’b’ to RUD-eye bolt ’RC’.

⇒ Insert and laterally fasten turning-out device 94155 (for engines with a 1-part

gear wheel 6) or turning-out device 94155a (for engines with a 2-part gear

wheel 6) as shown in Fig. ’B’.

⇒ The crankshaft is then to be turned with the turning gear pushing the pads out

which can then be lifted up and removed one by one as shown in Fig. ’C’.

Remark: When only a few thrust bearing pads of a row are to be removed the

crankshaft is located in its axial position by the remaining pads. When all thrust

bearing pads must be removed then the crankshaft must be prevented from sliding

axially. Therefore, insert a piece of hardwood of the same thickness in place of the

thrust bearing pad.

B C

I

I

6

I - I

II - II

012.959/05

012.960/05

II

II

a

b

5, 5a

RC

HZ

7

6

7

94155

94155a

94155

94155a

HZ

2010

Removal and Fitting the Thrust Bearing Pads

Loading...

Loading...