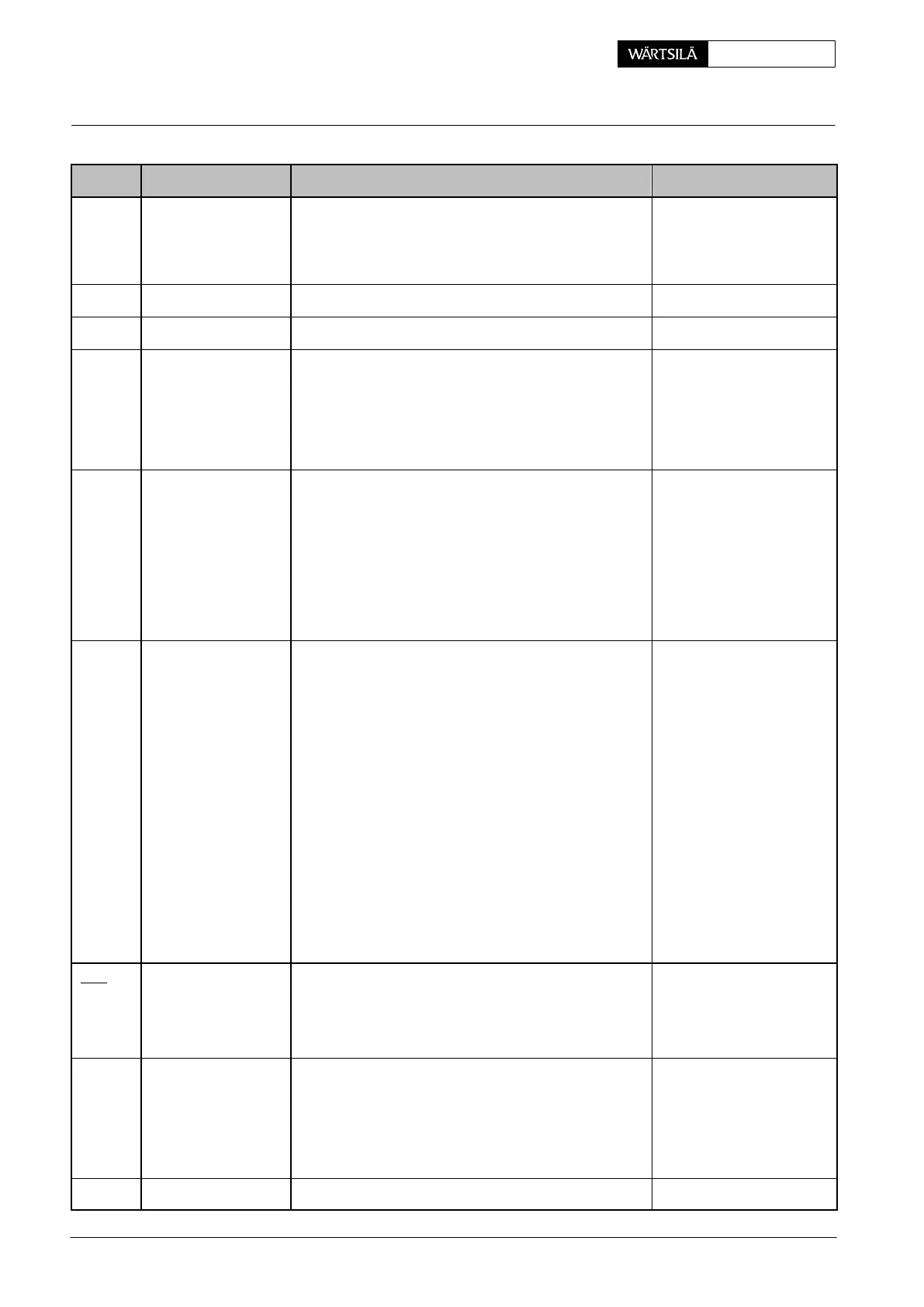

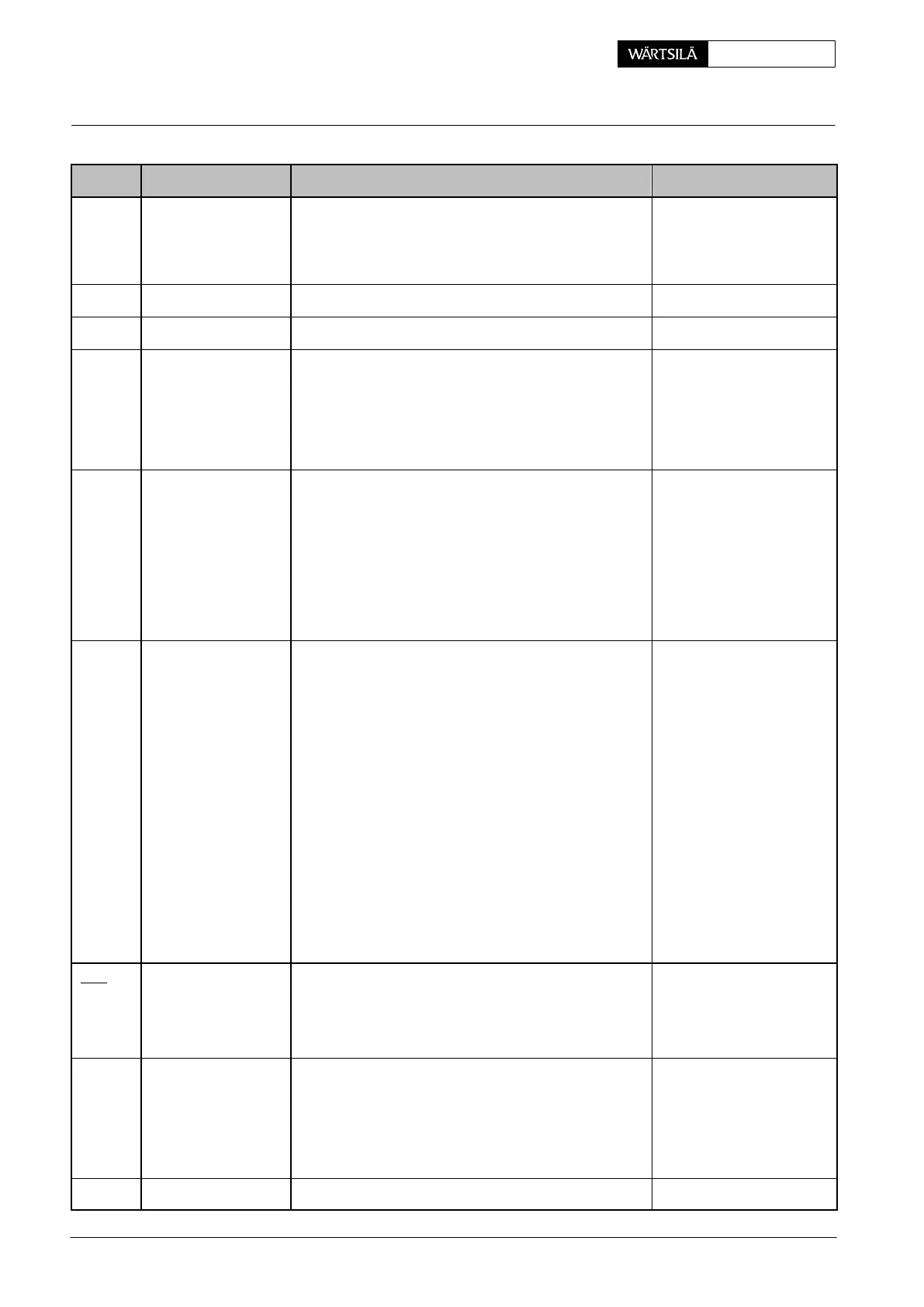

Maintenance0380−1/A1 RT-flex50-D

Wärtsilä Switzerland Ltd

2/ 7

Group Component Work to be carried out Intervals

2138−1 Lubricating quill

(pulse lubrication)

− Check function and tightness

− Check function of non-return valves

− Replace O-rings

at every piston removal

at every liner removal

at every liner removal

2303−1 Piston rod gland − Clean rings, establish wear at every piston removal

2708−1 Cylinder cover − Check combustion space for damage and wear at every piston removal

2722−1 Injection valve − Check externally for tightness before starting engine

after a longer standstill

− Check spray pattern, opening pressure, tightness

condition of nozzle tip, readjust opening pressure

(life time of nozzle tip about 6000 Op. h)

3000 Op. h

2728−1 Starting valve − Check piping before the valve during operation,

if piping is too hot, dismantle starting valve

weekly

− Remove and dismantle one starting valve at

random. From its condition determine time of

overhaul for remaining valves

6000−8000 Op. h

− Solenoid valve, random check

overhaul

6000 Op. h

18 000 Op. h

2751−1

to

Exhaust valve − General inspection of valve housing, valve

spindle and valve seat

(without dismantling of exhaust valve)

at every piston removal

2751−4 − Check condition and wear of valve spindle

(if necessary regrind seat by machining)

24 000−36 000 Op. h

− Check piston seal ring / air spring & rod seal ring /

guide bush

24 000−36 000 Op. h

− Check condition and wear of valve seat

(if necessary regrind seat by machining)

24 000−36 000 Op. h

− Random check of valve drive, outside and

inside pistons, damper, thrust piece

18 000 Op. h

− Random check of screwed connection to

measuring cone

18 000 Op. h

3

3103−1 Crankshaft − Measure crank deflection

(always in case of grounding of the ship as well as

before and after every docking)

6000−8000 Op. h

3130−1 Torsional

vibration damper

− Take a silicon oil sample from viscous vibration

damper (based on results of 1

st

sample, interval

for taking further samples will be decided)

first time after 15 000 −

18 000 Op. h

3130−2 − Inspection interval and dismantling of vibration

damper

acc. to instructions of

damper manufacturer

3146−1 Axial damper − Dismantling and inspection 36 000−48 000 Op. h

2010

nspection and Overhaul Intervals (Guidelines)

Loading...

Loading...