DMTA-10045-01EN, Rev. E, August 2016

Applications

133

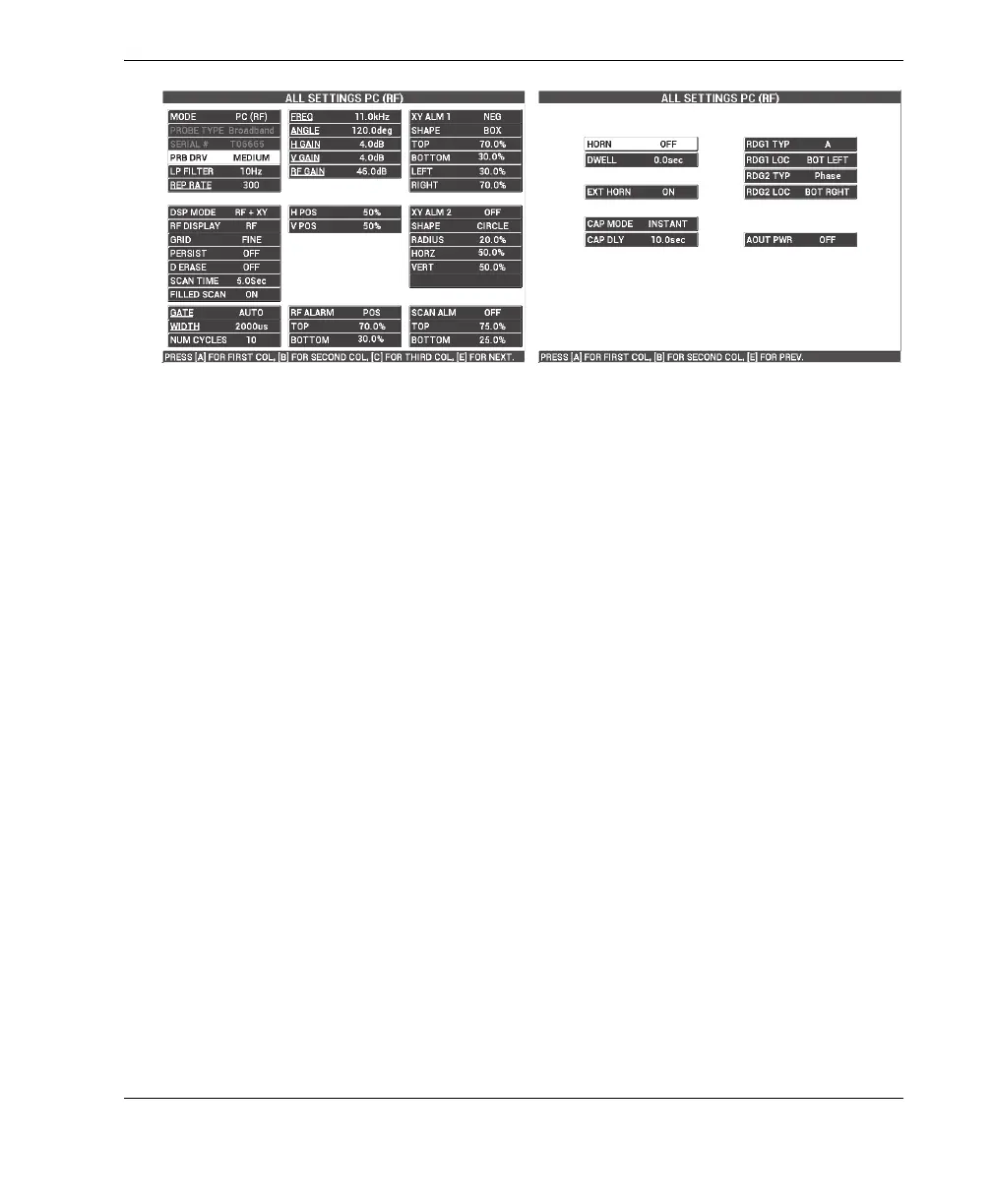

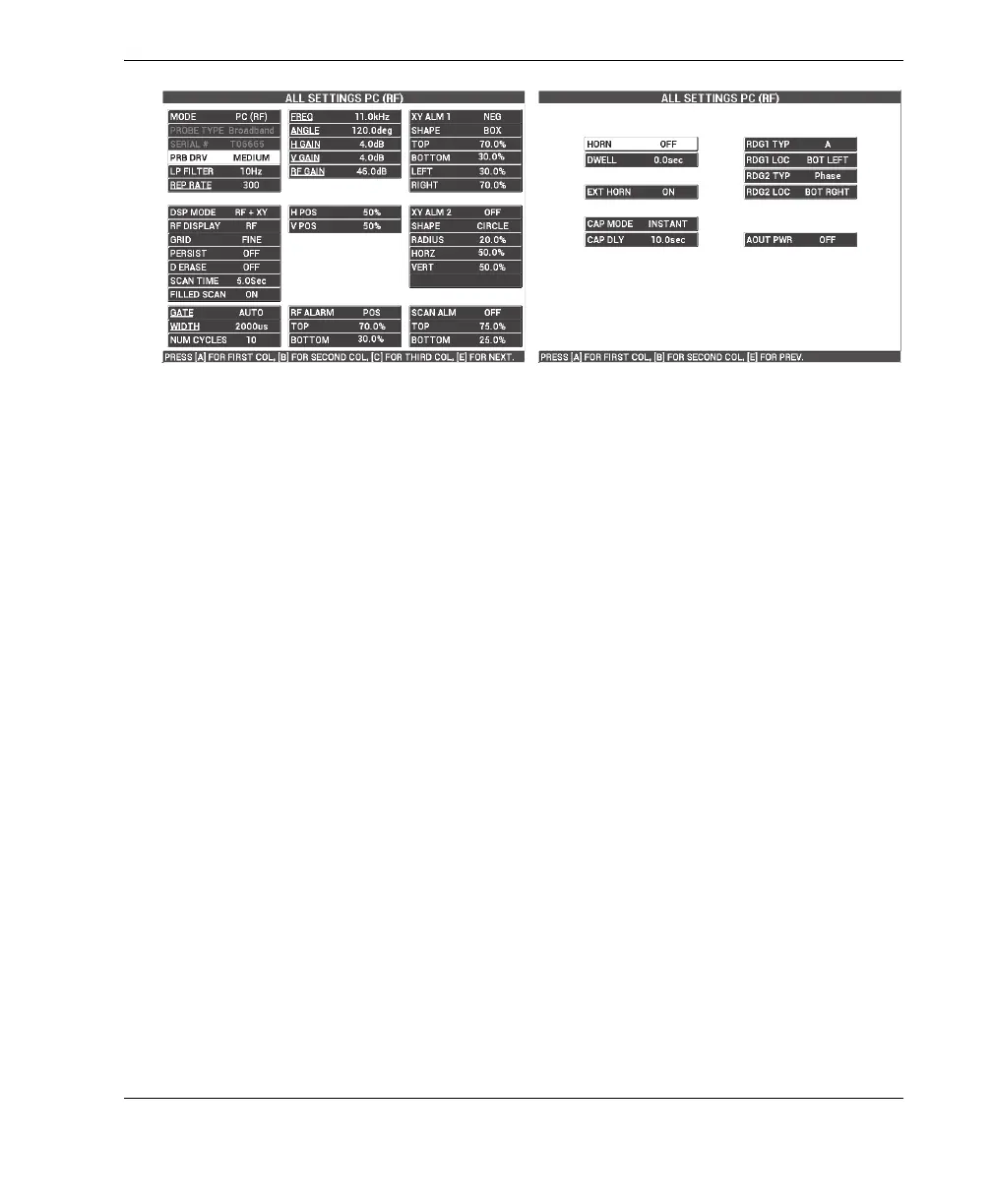

Figure 6‑16 The list of all parameters

6.1.2 Detecting Skin-to-Core Disbonds in Honeycomb Composite —

Tapered or Varying Geometry Using PC Swept Technique

The pitch-catch (PC) swept technique is ideal for inspecting honeycomb composite

parts with tapered or varying geometry. This technique works well on a variety of

skin and cores, but it works especially well with aluminum honeycomb cores.

The PC Swept technique typically works better for near-side disbonds than far-side

disbonds. It can also be used to inspect flatter or constant geometry parts, although

the RF and IMPULSE techniques are typically preferred for such parts, particularly

for thicker assemblies.

This procedure describes how to set up for a typical PC Swept inspection, using an

aluminum core standard. The choice of the frequency range (normally selected and

recommended by the part’s manufacturer) should be respected.

Inspection materials are shown in Figure 6-17 on page 134.

Loading...

Loading...