346

6 Maintenance of the knitting machine

Minimize wear

Wearing parts

Further information:

Adjusting needle brushes [214]

Yarn table [518]

Lubricate knitting machine [359]

Cleaning the knitting machine [347]

Adjusting the brushes of the central lubrication * [224]

Symbols in this document [16]

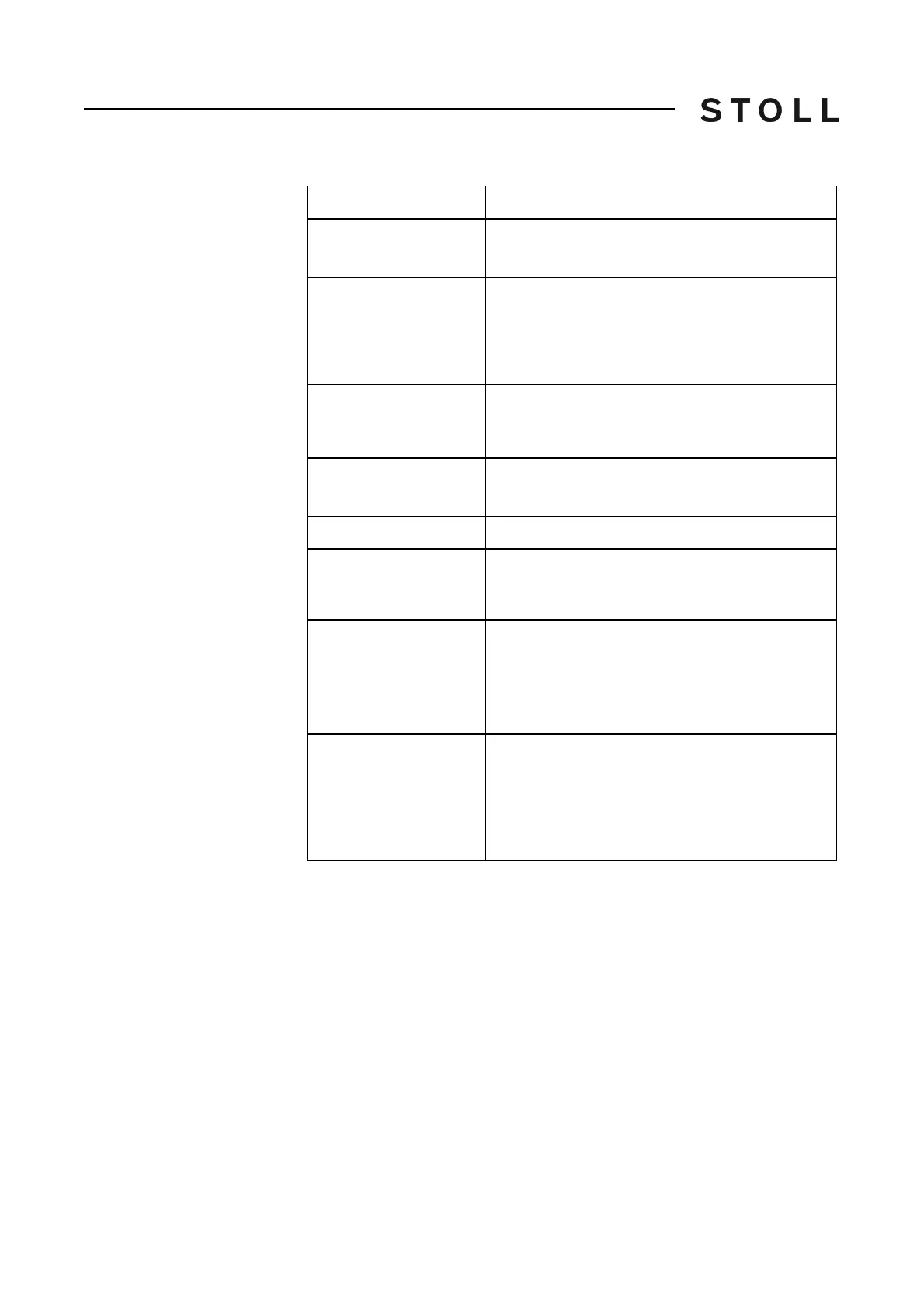

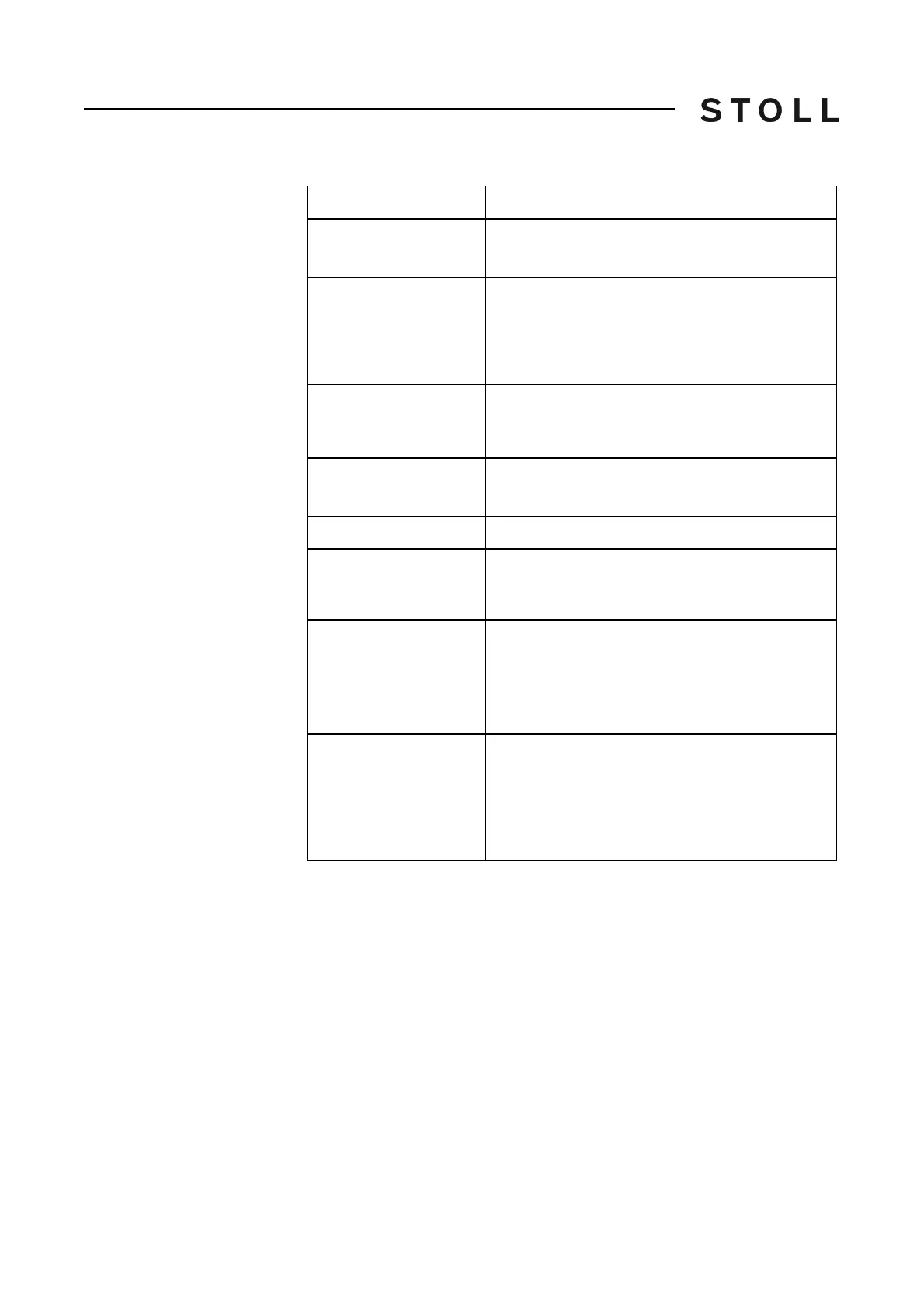

Feed wheel rollers

◆ Abrasive, sanding yarn

◆ Allowing the feed wheel to run unnecessarily

Needle bed elements,

cams

◆ Excessive fabric take-down values

◆ Yarn too thick

◆ Insufficient lubrication

◆ Insufficient cleaning

Yarn guiding parts

(deflectors, yarn control

device, etc.)

◆ Abrasive, sanding yarn

Yarn carrier, yarn carrier

sliding block

◆ Insufficient lubrication

◆ Abrasive, sanding yarn

Yarn carrier magnet

◆ Magnet may not come into contact with grease or oil

Belt on auxiliary take-

down

◆ Following a fault on the auxiliary take-down (fabric

winding device), the residual threads were not

removed carefully

Belts (drive, racking,

comb take-down,

auxiliary take-down)

◆ Belt tension too high: Danger of bearing damage

(adjustment with measuring device by Stoll

technician)

◆ Belt tension too low: Danger of position errors

(racking, auxiliary take-down)

Energy chain trailing

cable

◆ Heavy soiling

◆ Laying down of objects

◆ Damage to depositing gutter

◆ Not moved into position carefully after work at the

rear of the machine

Wearing part

Possible causes of increased wear

Loading...

Loading...