432

7 Repairing the knitting machine

Replacing parts

3. Mount the new belt in such a way that it runs in the grooves of the drive

pulley.

4. Press the motor (9) upward and tighten the screws of holes (7)

5. Check the belt tension.

The belt can be pushed through by approx. 2 to 4

mm when light pressure

is applied.

Change position of fri

ction

roller

The surface of the friction roller is worn over the course of time by the yarn.

Then the friction roller does not need to be replaced immediately, but its

position can be shifted by 11 mm. This doubles its service life.

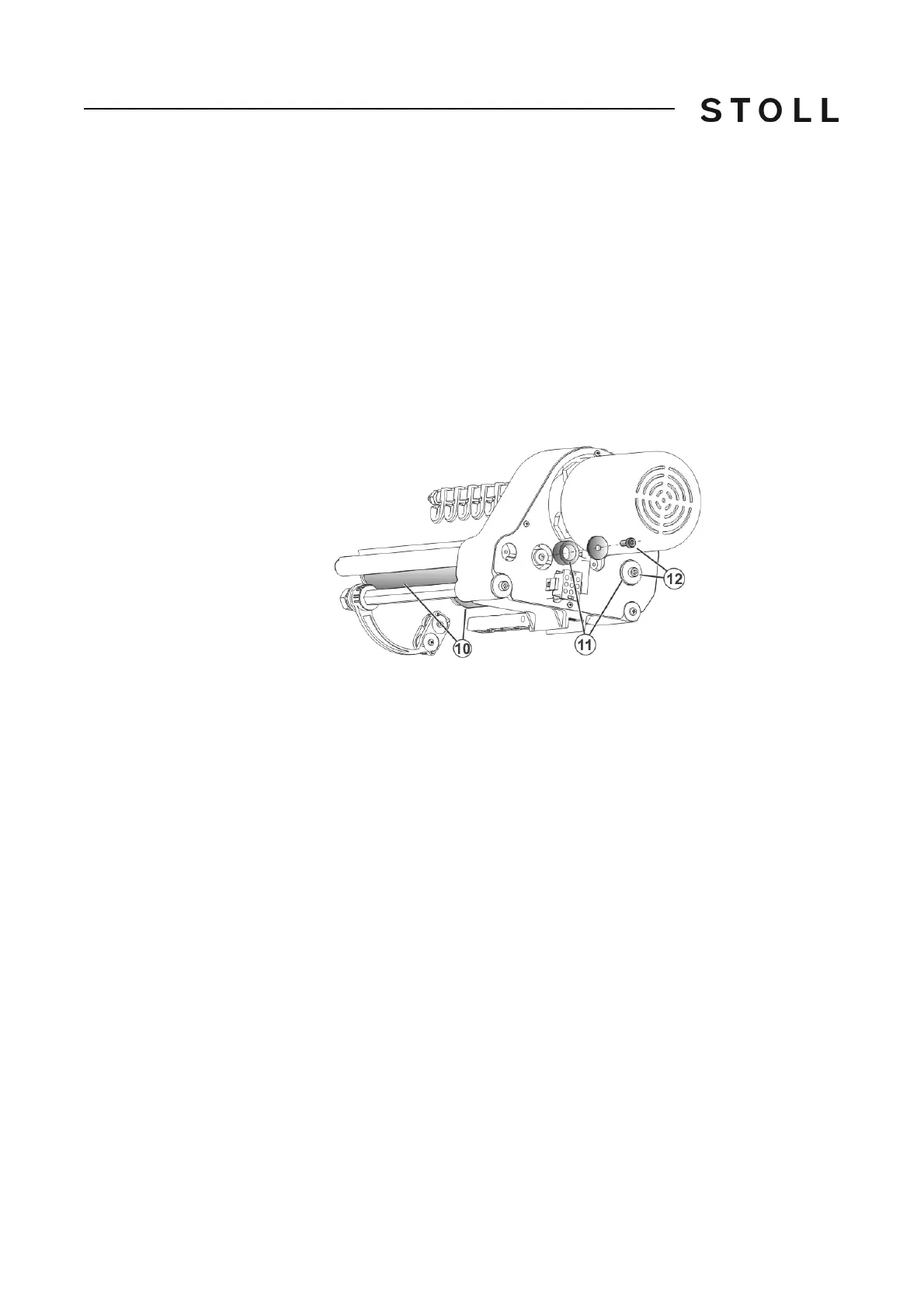

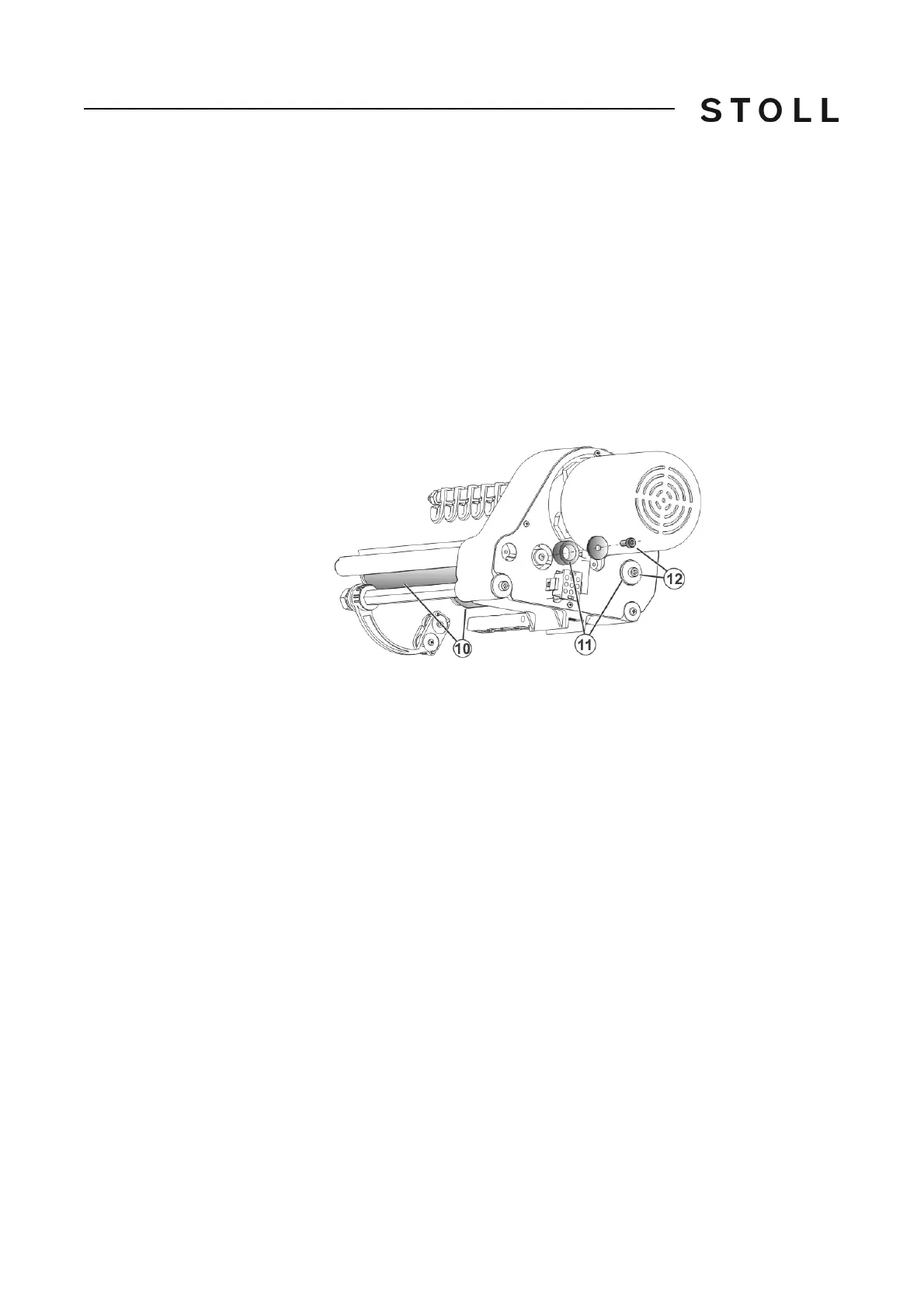

1. Remove the screws (12).

Screws for friction rollers

Screws for friction rollers

2. Remove the spacer (11).

3. Take off both friction rollers

(10).

4. To assemble: Push the space

r (11) onto the axis of the friction roller (10)

5. Reinstate the friction rollers (10).

6. Retighten the screws (12) without the spacers.

Replacing the friction roller 1. Remove the screws (12).

2. Take off the friction rollers (10).

3. Lay down the new friction roller.

4. Tighten the screws (12).

Loading...

Loading...