Maintenance

3603−1/A1

RT-flex50-D

Wärtsilä Switzerland Ltd

3/ 3

3. Fitting

⇒ Turn the corresponding crank to B.D.C.

⇒ Push ring holder 4 and sleeve 5 over inside pipe 6.

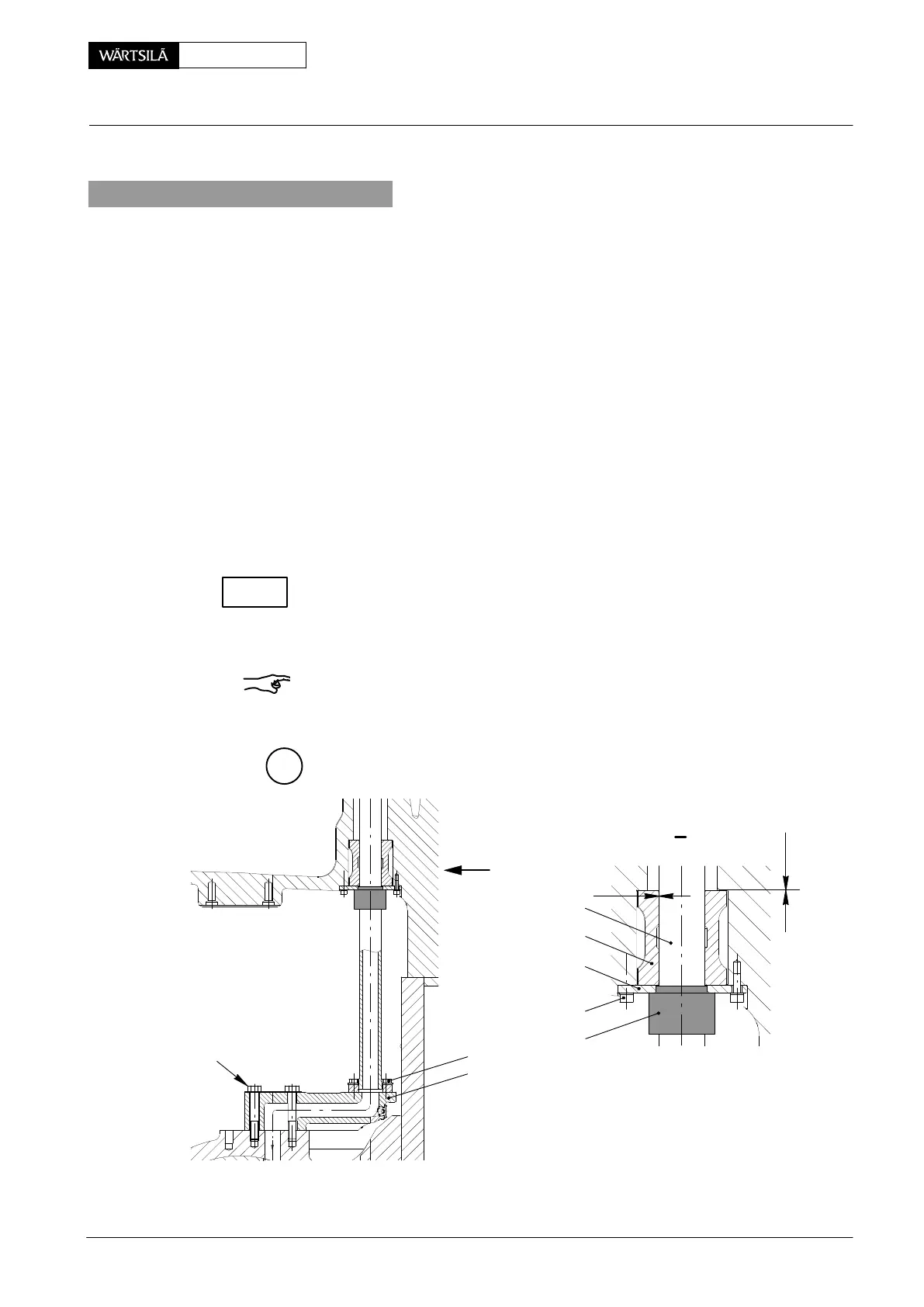

⇒ Fasten lifting tool 94337 to inside pipe and connect it to lifting tackle ’HZ’ as

shown in Fig. ’B’ view I.

⇒ Lift inside pipe, put it onto connection piece 8 and hold it loosely with screws 2

(Fig. ’C’).

⇒ Carefully turn the crank approx. 30_ after T.D.C.

⇒ Push up ring holder with sleeve into the bore of cylinder block 7 and hold them

loosely with screws 3.

⇒ Slightly tighten screws 2 and 3, that inside pipe and ring holder still can be

moved.

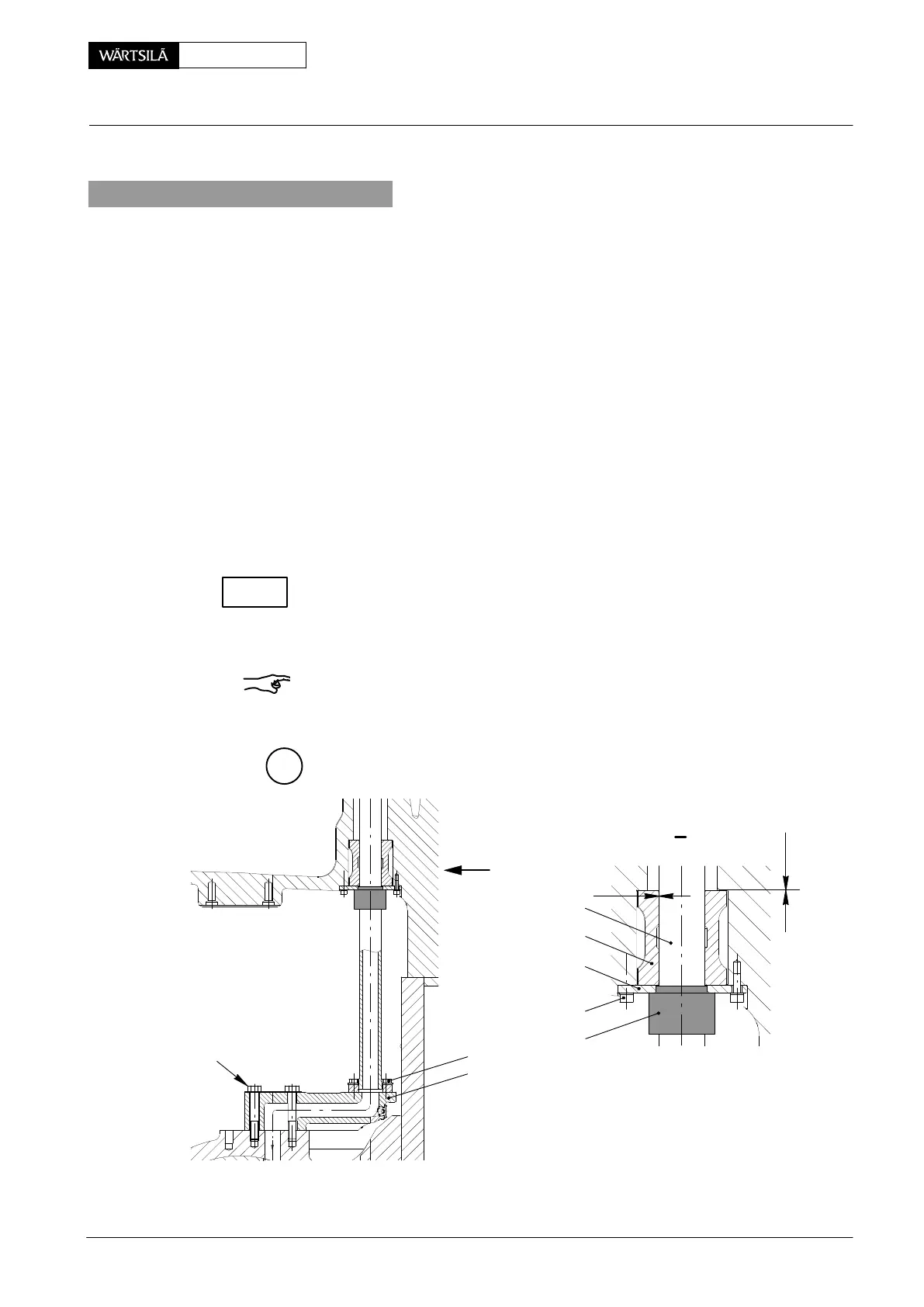

⇒ Align ring holder and inside pipe by means of centring piece 94337a till the

clearance ’x’ = 0.30 − 0.39 mm is adjusted.

⇒ Tighten screws 2 and 3.

Check clearance ’x

1

’ = 0.08 − 0.20 mm and recheck clearance ’x’.

⇒ Lock screws 2.

⇒ Install oil inlet pipe 1 (Fig. ’A’).

Remark: Every time if screws 2, 3 or 10 have been loosened, inside pipe 6 must be

aligned and clearances ’x’ as well as ’x

1

’ checked.

F

013.418/05

013.419/05

94337a

I

2

8

6

5

4

3

x

x

1

I

10

Piston Cooling and Crosshead Lubrication: Removal and Fitting of Inside Pipe

2010

CHECK

Loading...

Loading...