Maintenance

8460−1/A1

RT-flex50-D

Wärtsilä Switzerland Ltd

3/ 3

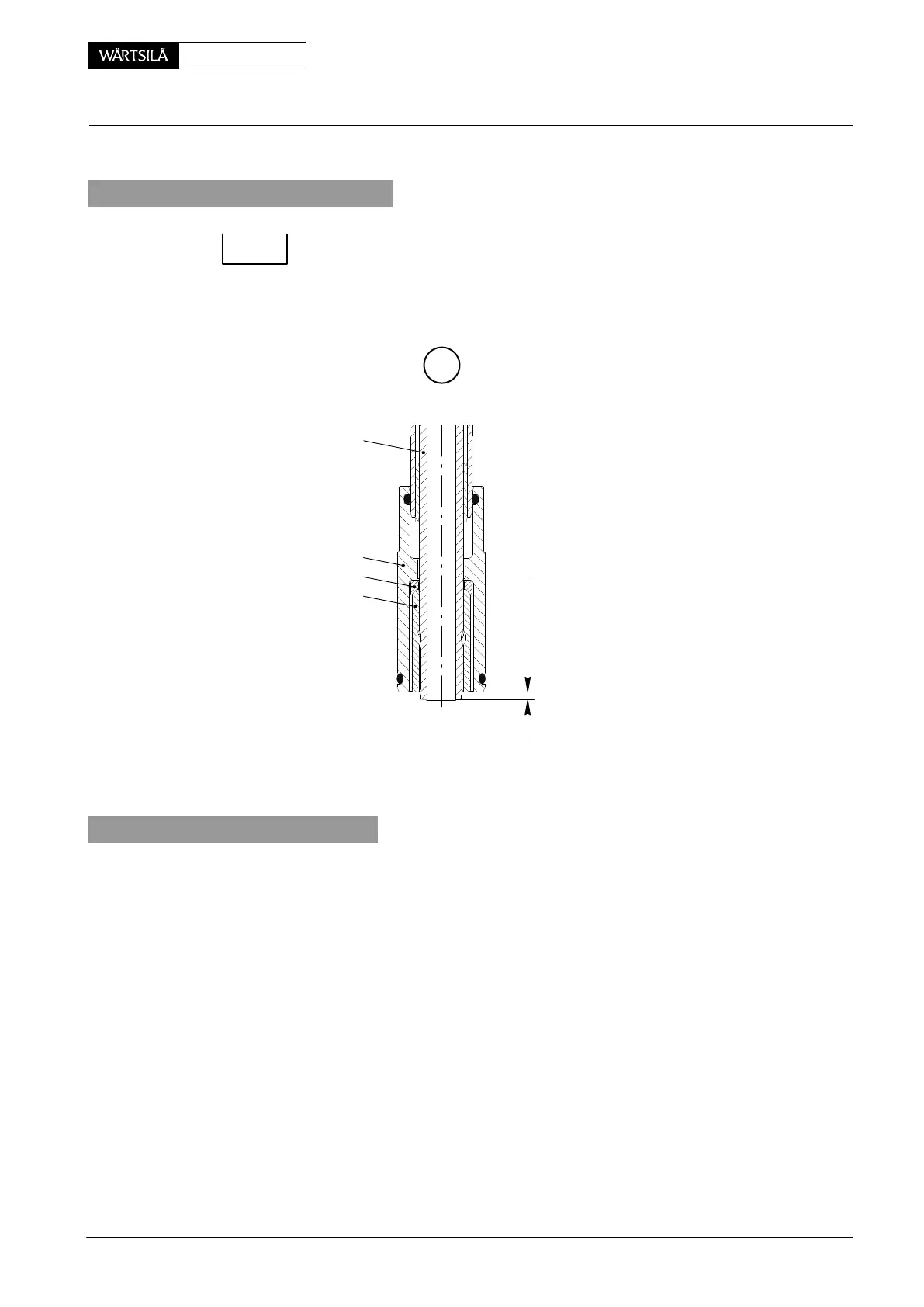

3. Adjusting the claws

Before fitting hydraulic piping 1 check whether its claws 6 are screwed on properly

(Fig. ’D’), i.e. the hydraulic piping must protrude by ’x’ = 5.5 mm compared to the

claw.

Measure ’x’ can be adjusted by turning the claw using an open-end wrench.

D

013.461/05

x = 5.5 mm

1

7

6

5

4. Fitting

D Fitting together should be carried out axially, i.e. the parts to be connected

must not be moved closer together laterally, in order to avoid any damaging

of sealing faces DF.

D Oil the threads of screws 4 (Fig. ’A’) and tighten them crosswise with a torque

of 20 Nm.

D After assembly retighten drain screw 8 with a torque of 200 Nm.

ydraulic Piping: Removing, Fitting and Regrinding

2011-12

CHECK

Loading...

Loading...