Maintenance

0352−1/A1

RT-flex50-D

Wärtsilä Switzerland Ltd

5/ 16

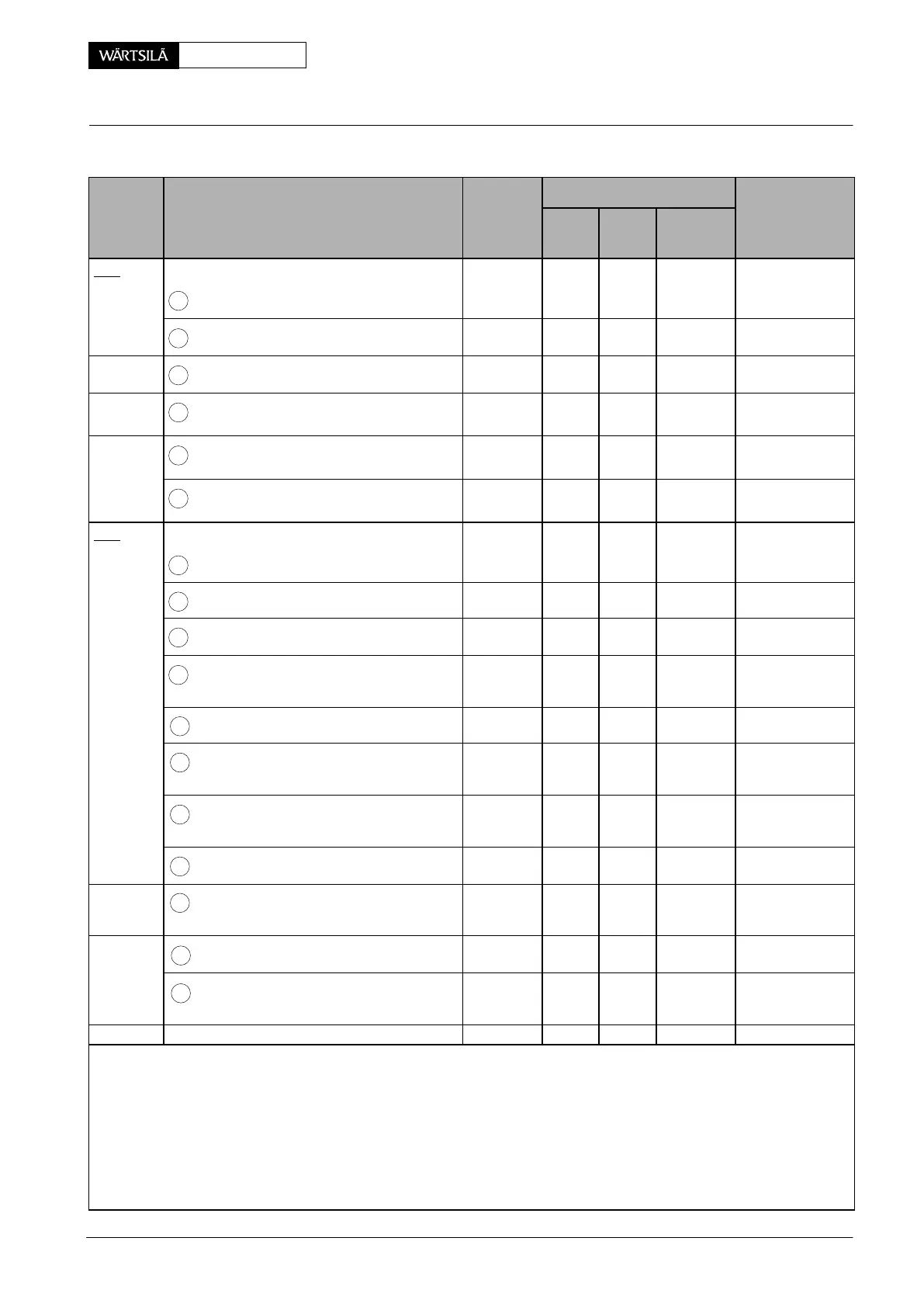

Group Description Thread Tightening values Lubricant

1

[bar]

2

[Nm]

3

[_(; mm]

8

8447−1

Screwed connection to servo oil pipe

58

M10 & 12 40

Oil

Non-return valve

59

G¼”

25

Oil

8460−1

Screwed connection to hydr. pipe

60

M8x90 20

Oil

8733−1

Flange − injection valve, screw

61

M10 40

Never-Seez

NSBT-8

8752−1

Fuel pressure piping, screw

62

M12 55

Never-Seez

NSBT-8

*

Valve housing − fuel rail, screw

63

M16 150

Never-Seez

NSBT-8

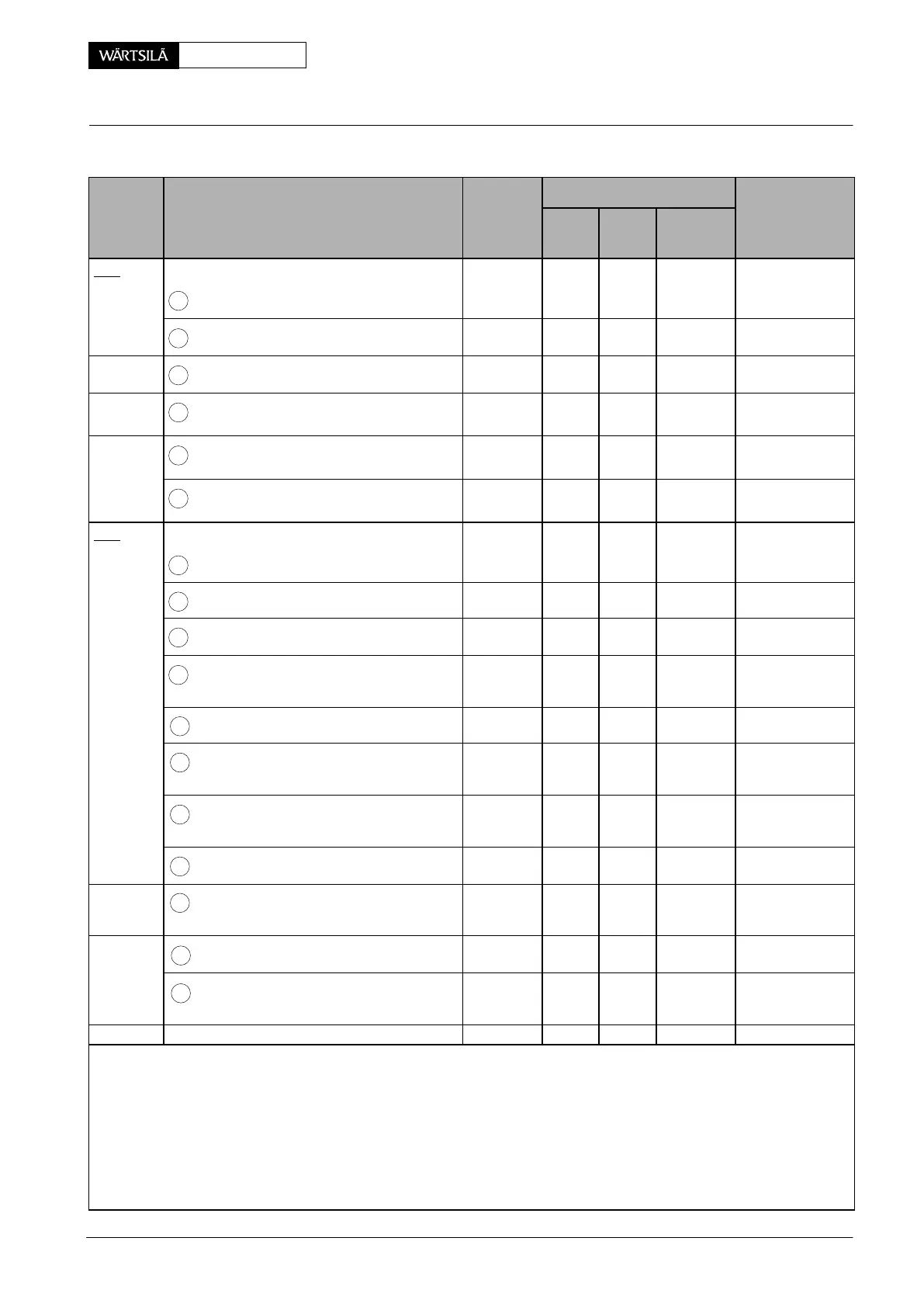

9

9223−1

Nut to waisted screw

64

M16 140

MOLYKOTE G

Shaft nut

65

M40x1.5 25

MOLYKOTE G

Shaft nut

66

M35x1.5 25

MOLYKOTE G

Screw to shaft encoder − bearing

housing

67

M8 16

MOLYKOTE G

Screw to distance piece

68

M12 60

MOLYKOTE G

Screw to connecting unit − driving

wheel

69

M12 60

MOLYKOTE G

Screw to spring tensioner − coupling

disc

70

M12 60

MOLYKOTE G

Screw to spring tensioner

71

M10 35

MOLYKOTE G

9923 *

Connecting unit, adjusting disc −

coupling disc, screw

72

M10 35

MOLYKOTE G

9314 *

Clamping nut to oil mist detector

73

G ¾”

15

Oil

*

Screws for opening head of oil mist

detector

74

5

Oil

1 When using other hydraulic jacks, required pressure in bar must be calculated in relation to effective jack piston surface!

Conversion factor: 1 Nm = 0.102 mkp 1 bar = 1.02 kp/cm

2

2 Tightening torque

3 Tightening angle or elongation

− Numbers in

f refer to illustrations on pages 7 to 16.

− Values in parentheses (...) are for information only, to be used for comparison.

− Screwed connections must be tightened in accordance with values not in parentheses.

Respective lubricant has to be applied to threads and seating surfaces, if no other instructions are mentioned.

− Bostik Findley Inc. (USA) is manufacturer of Never-Seez NSBT-8.

* Tightening procedure not mentioned in this Manual.

2011-12

ightening Values of Important Screwed Connections

Loading...

Loading...