Maintenance0352−1/A1 RT-flex50-D

Wärtsilä Switzerland Ltd

4/ 16

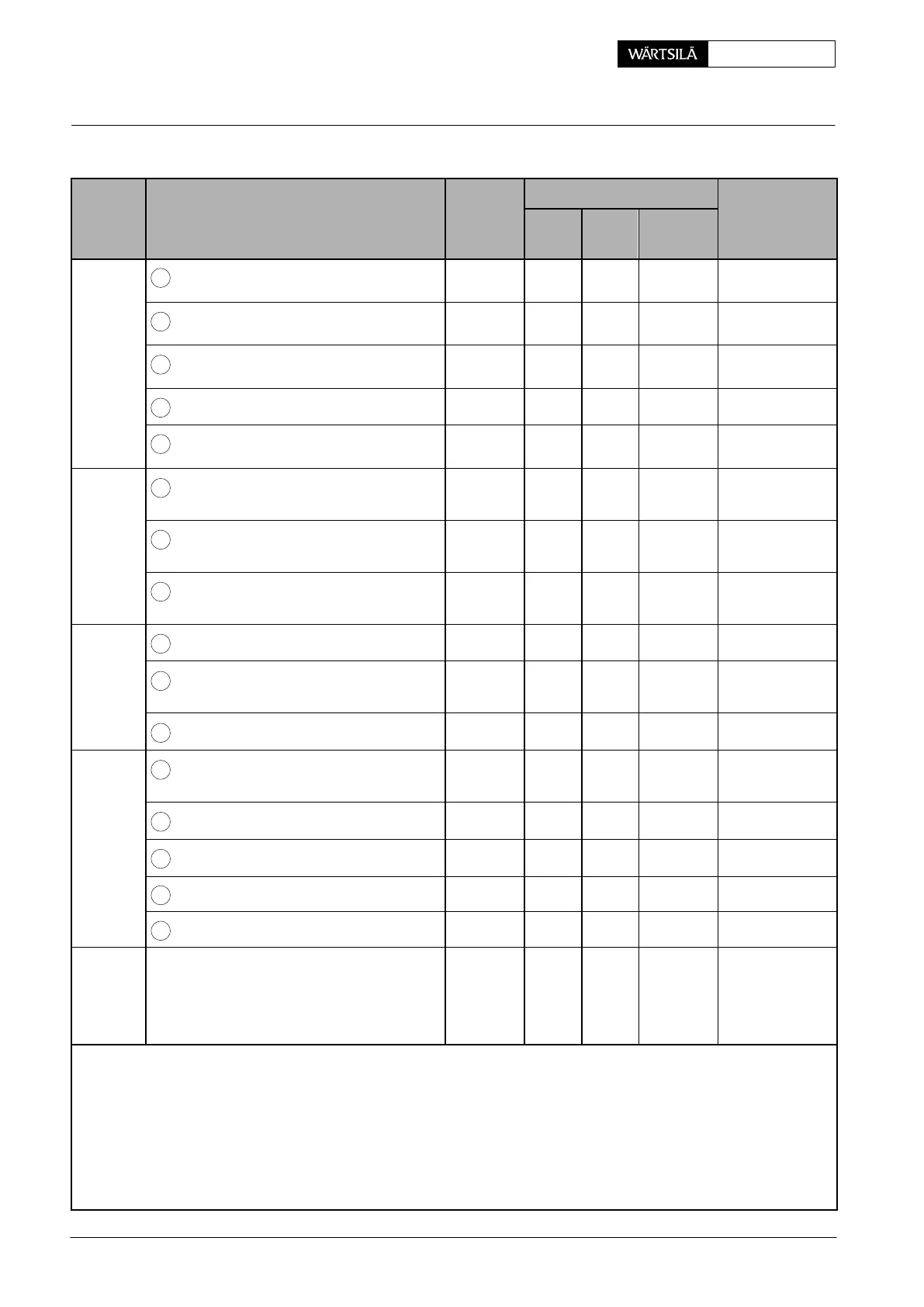

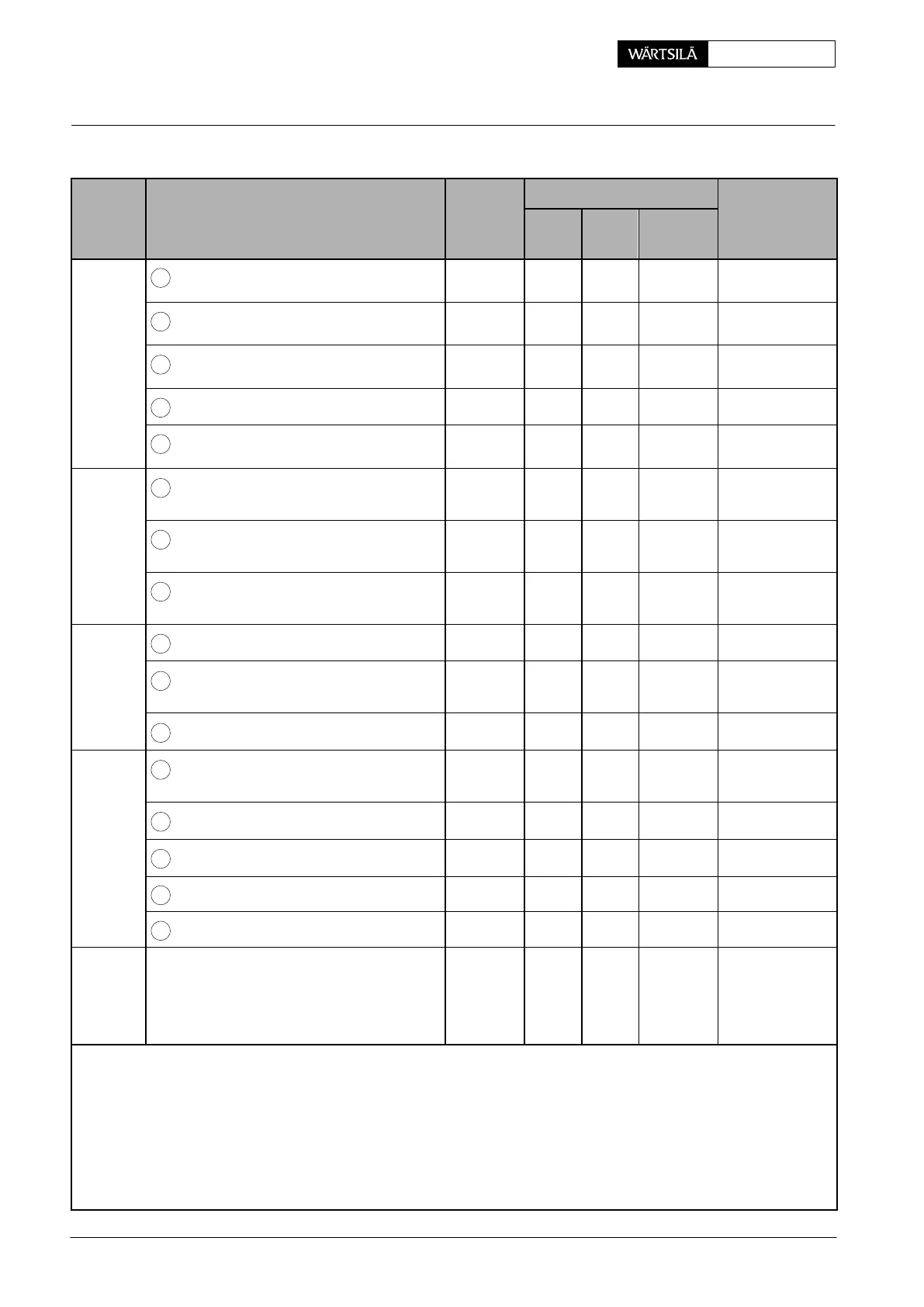

Group Description Thread Tightening values Lubricant

1

[bar]

2

[Nm]

3

[_(; mm]

5564−1

Injection control unit − fuel rail, screw

42

M16 110

Never-Seez

NSBT-8

Injection control unit − fuel rail, screw

43

M12 55

Never-Seez

NSBT-8

Screw to pre-control valve

44

M4 2.5

Never-Seez

NSBT-8

Filter holder

45

R ¾”

120

Oil

Connecting nipple

46

M42x2 350

Never-Seez

NSBT-8

5564 *

Fuel quantity sensor − fuel quantity

housing, screw

47

M8 20

Never-Seez

NSBT-8

*

Fuel quantity housing − intermediate

flange, screw

48

M10 25

Never-Seez

NSBT-8

*

Fuel quantity sensor − fuel quantity

housing, screw

49

M12 75

Never-Seez

NSBT-8

5610 *

Pressure transmitter

50

G¼”

25

Oil

*

Screwed connection to end cover −

servo oil rail

51

M16 160

Oil

Drain screw

52

M20 200

Oil

5612−1

Exhaust valve control unit − servo oil

rail, screw

53

M16 170

Oil

Cover − valve housing, screw

54

M10

40

Oil

Orifice

55

M10 10

Oil

Oil filter

56

M33 225

Oil

Screw to pre-control valve

57

M4 2.5

Oil

1 When using other hydraulic jacks, required pressure in bar must be calculated in relation to effective jack piston surface!

Conversion factor: 1 Nm = 0.102 mkp 1 bar = 1.02 kp/cm

2

2 Tightening torque

3 Tightening angle or elongation

− Numbers in

f refer to illustrations on pages 7 to 16.

− Values in parentheses (...) are for information only, to be used for comparison.

− Screwed connections must be tightened in accordance with values not in parentheses.

Respective lubricant has to be applied to threads and seating surfaces, if no other instructions are mentioned.

− Bostik Findley Inc. (USA) is manufacturer of Never-Seez NSBT-8.

* Tightening procedure not mentioned in this Manual.

2011-12

ightening Values of Important Screwed Connections

Loading...

Loading...