Chapter 2 Troubleshooting

2.3 Level 2 FIP

2-15

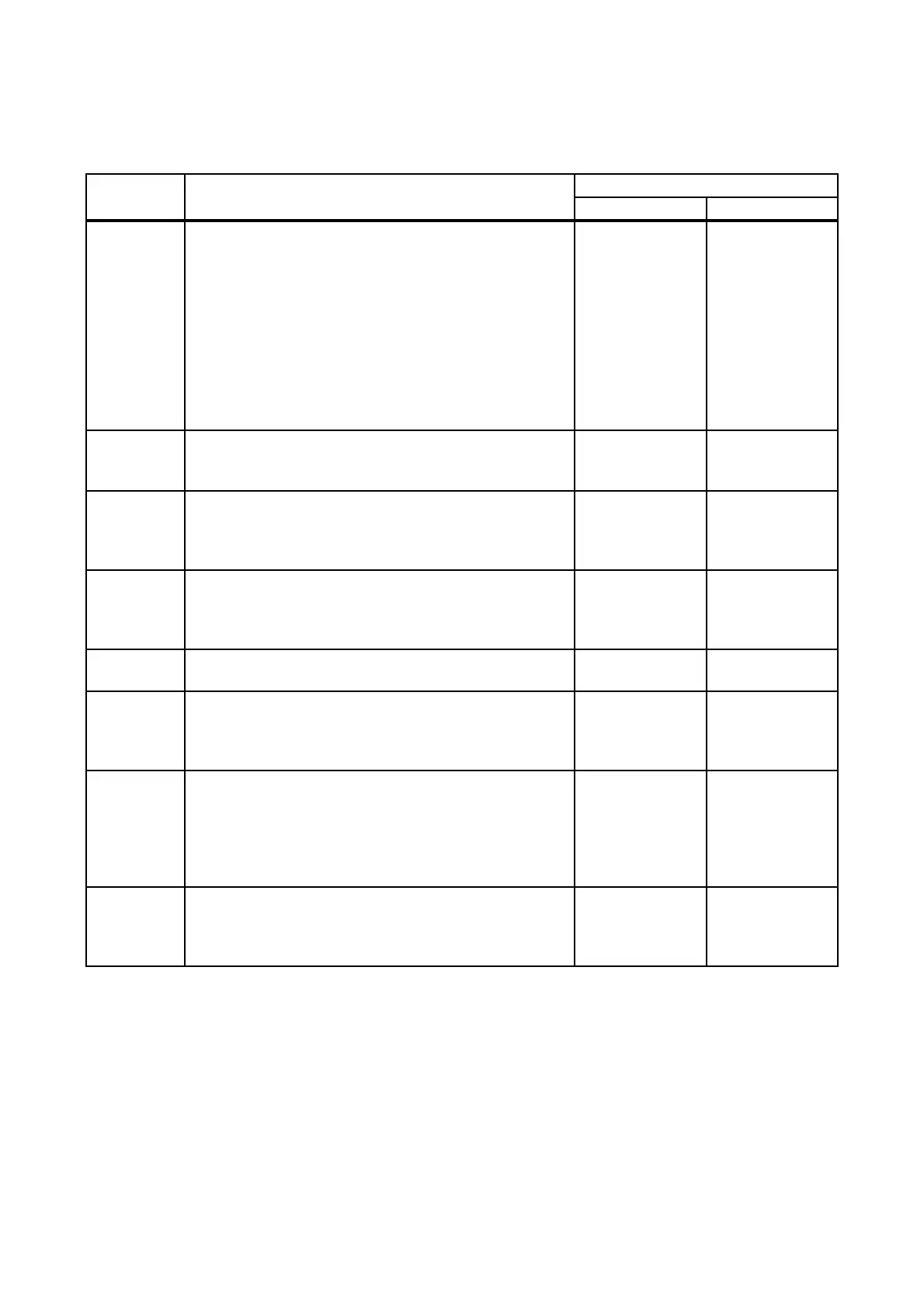

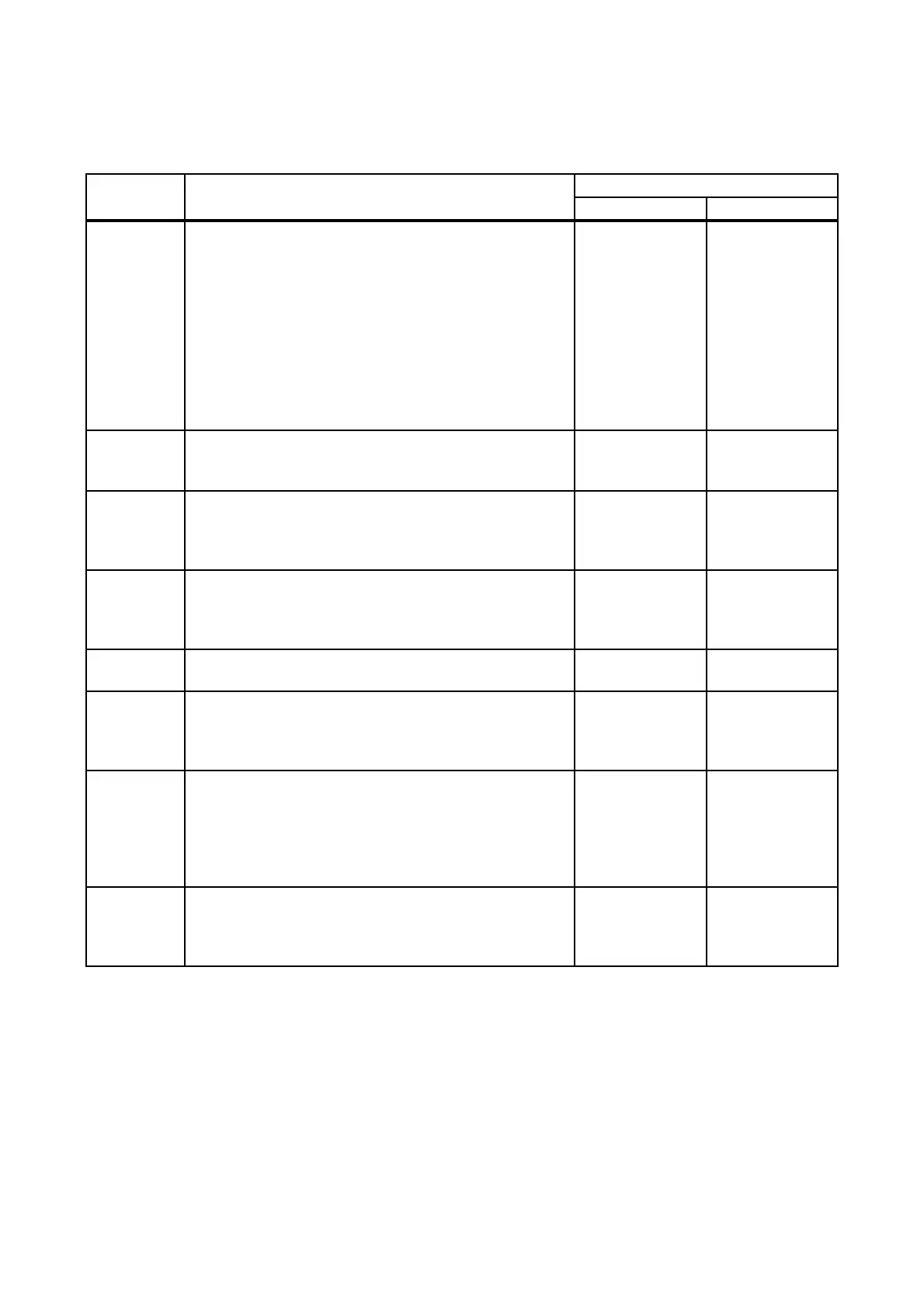

FIP-1.5 Too quick jam (jam or pick error)

*: Do not absolutely touch the powered parts, high-voltage output parts, and driving parts for check.

Procedure Check

Action

YES NO

1

- Initial check -

Are there errors such as use of parts in different

specifications, attachment error, damage,

transformation, dirt, or foreign object?

- Major check parts -

GEAR ASSY (PL7.1.1), ROLL ASSY FEED REAR

(PL5.1.36), FEED MOTOR ASSY (PL5.1.28), PWBA

SENSOR (PL4.1.17), REGI SENSOR (mounted on the

PWBA SENSOR), ACTUATOR ASSY REGI

(PL4.1.19),Paper Cassette, PWBA MCU XFABK(B)

(PL9.1.25)

Replace and

reattach the parts.

To step 2

2

- Paper size check -

Is the paper size based on the specifications? To step 3

Use the paper

based on the

specifications.

3

Does any paper remain in the ACTUATOR ASSY

REGI? Remove the

paper.

- There is a too.

To step 4

- There is no tool.

To step 5

4

- MOTOR ASSY MAIN check - *

Does the MOTOR ASSY MAIN rotate normally?

Select [MOTOR ASSY MAIN TEST] on the

DIAGNOSTIC MODE MENU.

To step 5

Go to FIP-2.7,

GEAR ASSY

error

5

- ROLL ASSY FEED REAR rotation check - *

Does the ROLL ASSY FEED REAR rotate normally?

To step 7 To step 6

6

- FEED MOTOR ASSY check - *

Does the FEED MOTOR ASSY rotate normally?

To step 7

Replace the

FEED MOTOR

ASSY

7

- ACTUATOR ASSY REGI check -

Does the ACTUATOR ASSY REGI run smoothly?

- There is a tool.

To step 8

- There is no tool.

Go to FIP-2.4,

PWBA SENSOR

error

Replace the

ACTUATOR

ASSY REGI

8

- REGI. SENSOR check -

Does the REGI. SENSOR function normally?

Select [SENSOR/SWITCH CHECK] on the

DIAGNOSTIC MODE MENU.

Replace the

PWBA MCU

XFABK(B)

Go to FIP-2.4,

PWBA SENSOR

error

Loading...

Loading...