● After auto-tuning is completed, the respective optimal values are stored for proportional gain

[Kp], integral time [Ti], and derivative time [Td]. Before execution, it is necessary to specify

appropriate values (e.g. lower limits) within the respective setting ranges.

● After auto-tuning is complete, store optimal values for proportional gain [Kp], integral time

[Ti], and derivative time [Td]. Be careful that the stored values are not rewritten.

● During auto-tuning, the values for Kp, Ti and Td are calculated by measuring changes to

process values (PVs) when manipulated values (MVs) are set to the upper limits, as well as

changes to process values (PVs) when manipulated values (MVs) are set to the lower limits,

so that process values (PVs) will be increased or decreased in accordance with the

respective set point values (SPs).

● Changes to manipulated values (MVs) of auto-tuning are completed in three sessions (upper

limit output - lower limit output - upper limit output) in the fewest times possible. If the auto-

tuning progress does not change from 0 after multiple sessions, shorten the control interval

Ts and retry auto-tuning.

■

Overview of PID control

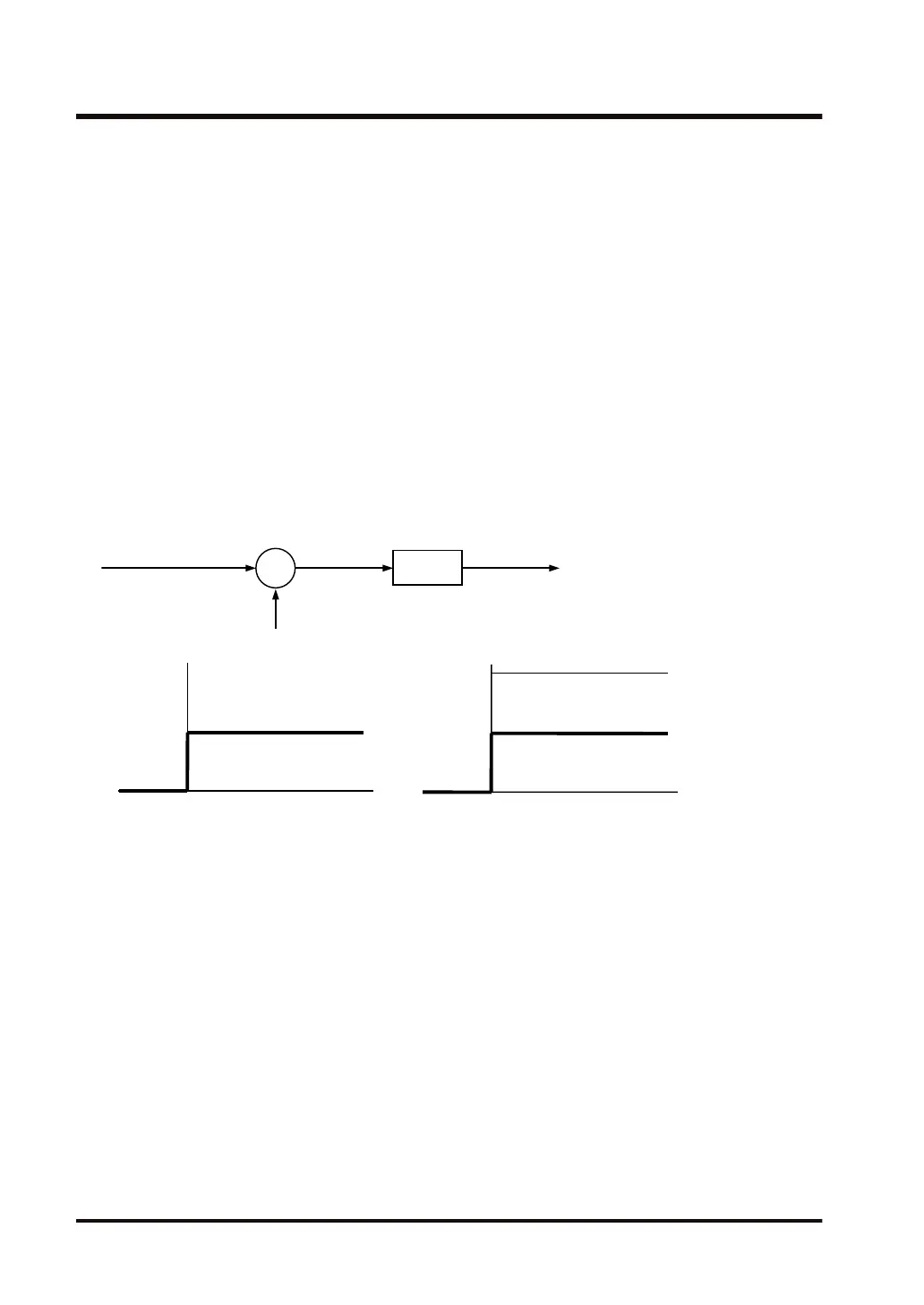

(1) Proportional operation

Control operation that produces an output proportional to the size of the input

Setting signal SV

+

ー

Measurement signal PV

Deviation e

Kp

Output MV

e

1

0

t

MV

1

0

t

2

0.5

Kp=2

Kp=1

Kp=0.5

● A constant control quantity is maintained.

● Offset (steady-state deviation) remains.

● The larger the Kp value, the stronger the action of the proportional operation.

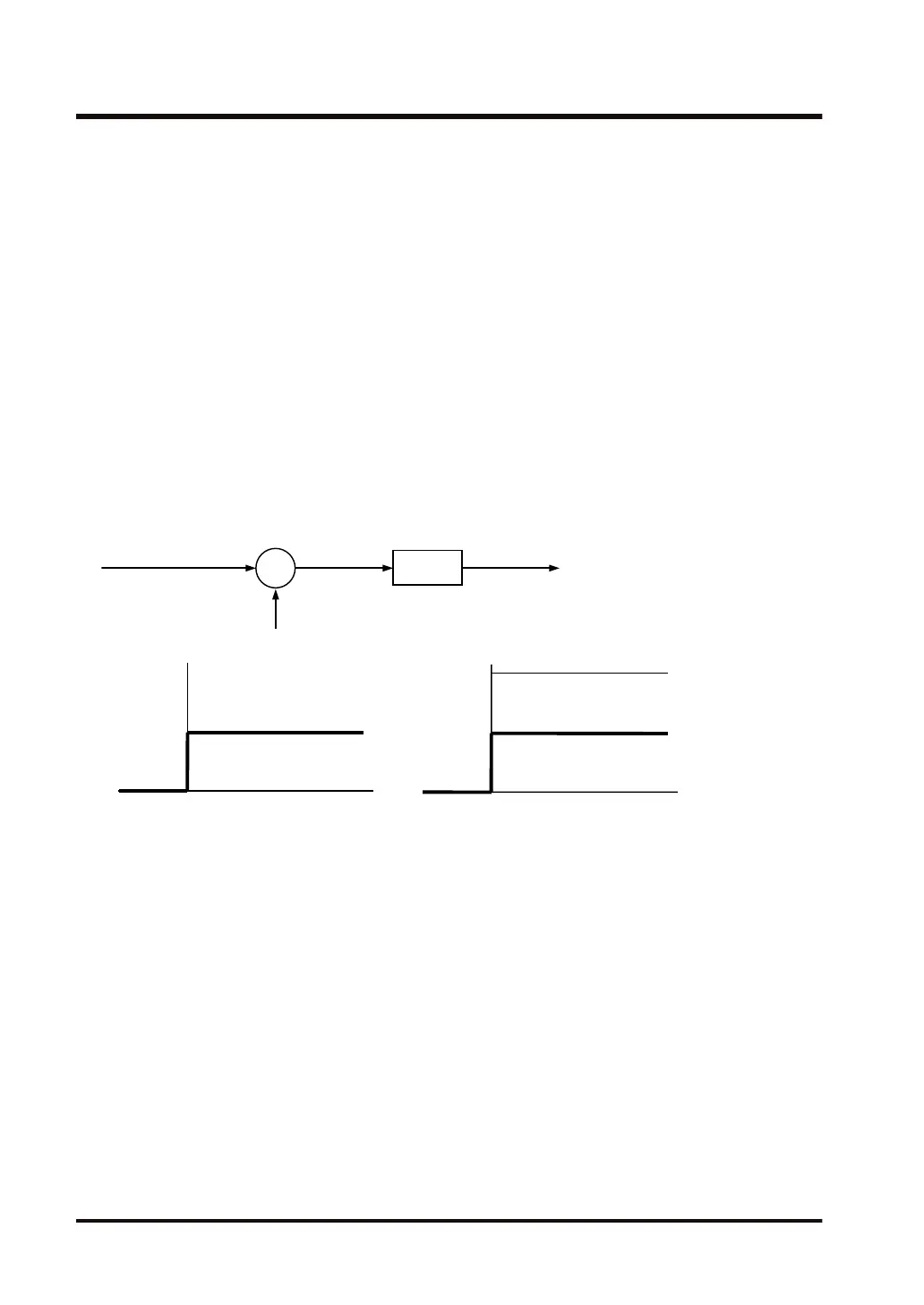

(2) Integral operation

Control operation that produces an output proportional to the integral time of the input.

10.11 PID (PID Operation)

10-42 WUME-FP7CPUPGR-12

Loading...

Loading...