10.12 EZPID (PID Operation: PWM Output Available)

■

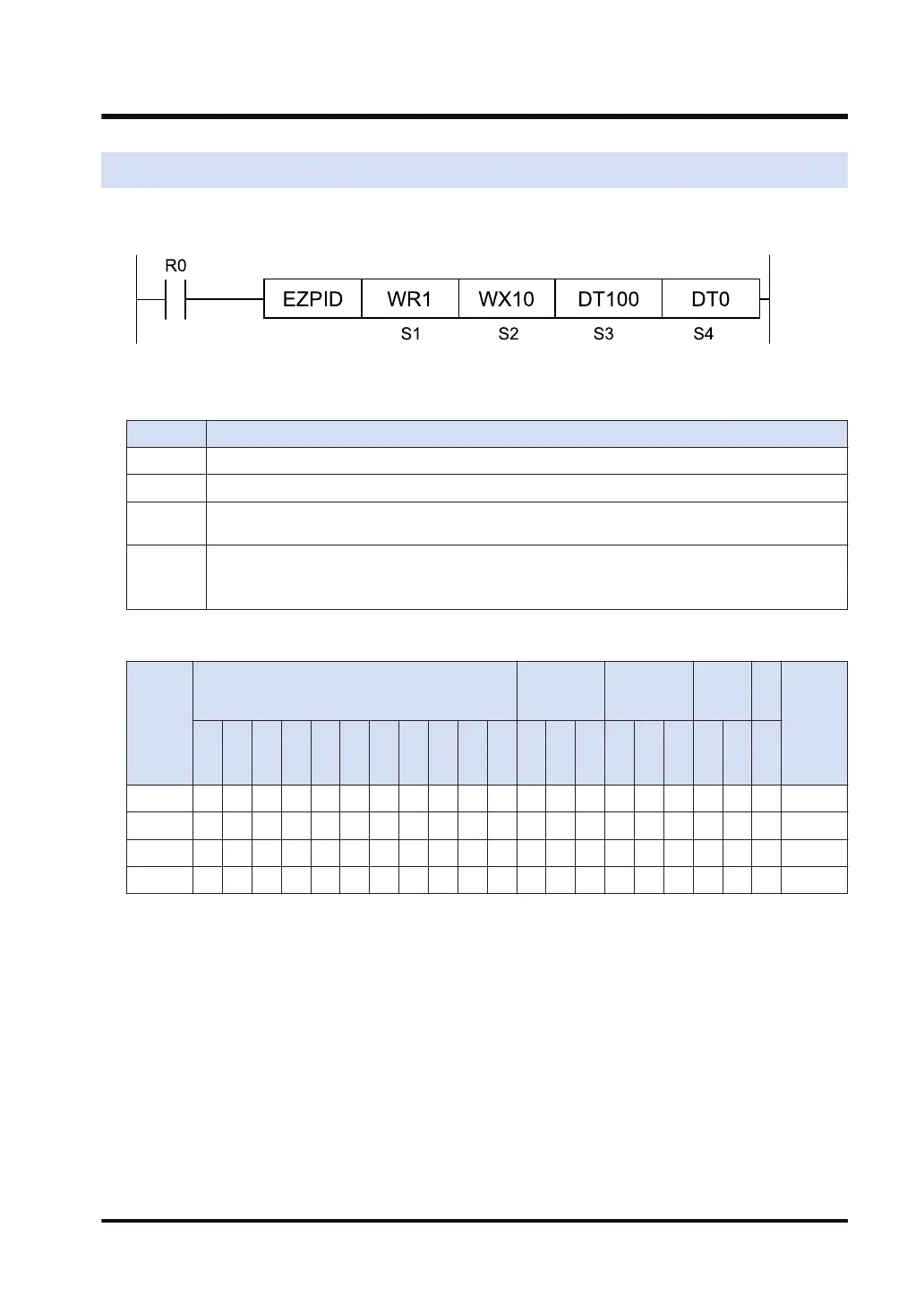

Ladder diagram

■

List of operands

Operand Description

S1 1-word area for setting control data that determine methods for auto-tuning and output

S2 1-word area for inputting the process value (PV)

S3

4-word area for setting the set point value (SV), proportional gain (Kp), integral time (Ti), and

derivative time (Td).

S4

30-word area comprising the following:

Storage area for the manipulated value (MV), control interval (Ts), control mode, setting area for

parameters related to auto-tuning, and operation work area

■

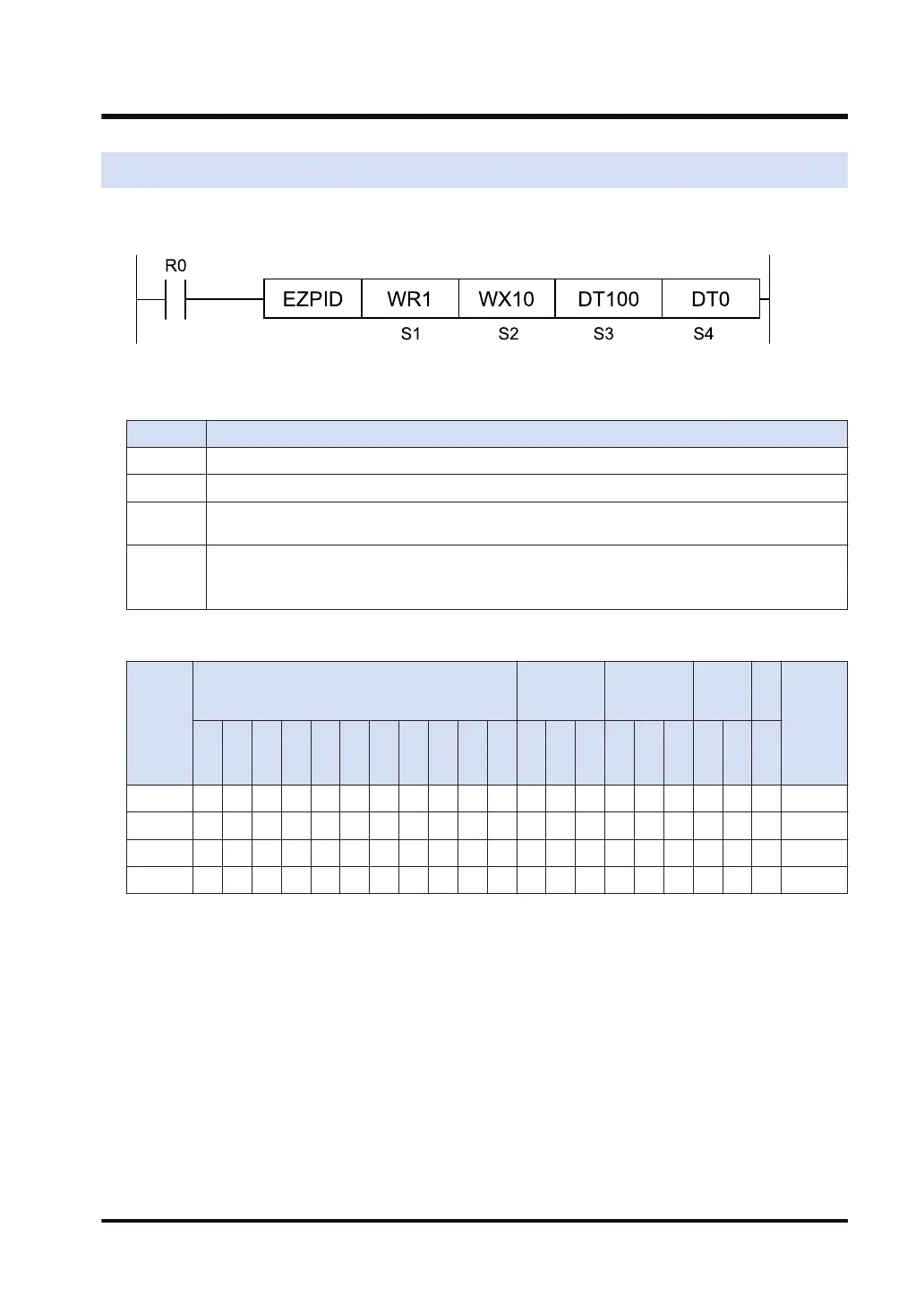

Devices that can be specified (indicated by ●)

Operan

d

16-Bit device:

32-Bit

device:

Integer

Real

numbe

r

St

rin

g

Index

modifie

r

W

X

W

Y

W

R

W

L

W

S

S

D

D

T

L

D

U

M

WI

W

O

TS

C

S

TE

C

E

IX K U H SF

D

F

" "

S1 ● ● ● ● ● ●

S2 ● ● ● ● ● ● ● ●

S3 ● ● ● ● ● ●

S4 ● ● ● ● ● ●

■

Outline of operation

● PID operation is carried out to retain the process value (PV) stored in [S+2], in consistency

with the set point value (SP) specified by [S3].

● The operation result is stored, as a manipulated value (MV), in the area specified by [S4]. If

an OUT instruction is described immediately after this instruction, PWM output (ON-OFF

output) can be gained, proportionate to the manipulated value.

● Set the parameters used for PID operation (proportional gain, integral time, and derivative

time) to [S3+1] to [S3+3]. The auto-tuning function for automatically calculating these values

is also available.

● To change the method for PID operation (derivative-first operation/proportional-plus-

derivative-first operation, reverse operation/forward operation) or the control interval Ts, etc.,

set them to the area [S4] to [S4+9].

10.12 EZPID (PID Operation: PWM Output Available)

WUME-FP7CPUPGR-12 10-45

Loading...

Loading...