Maintenance2138−1/A2 RT-flex50-D

Wärtsilä Switzerland Ltd

2/ 4

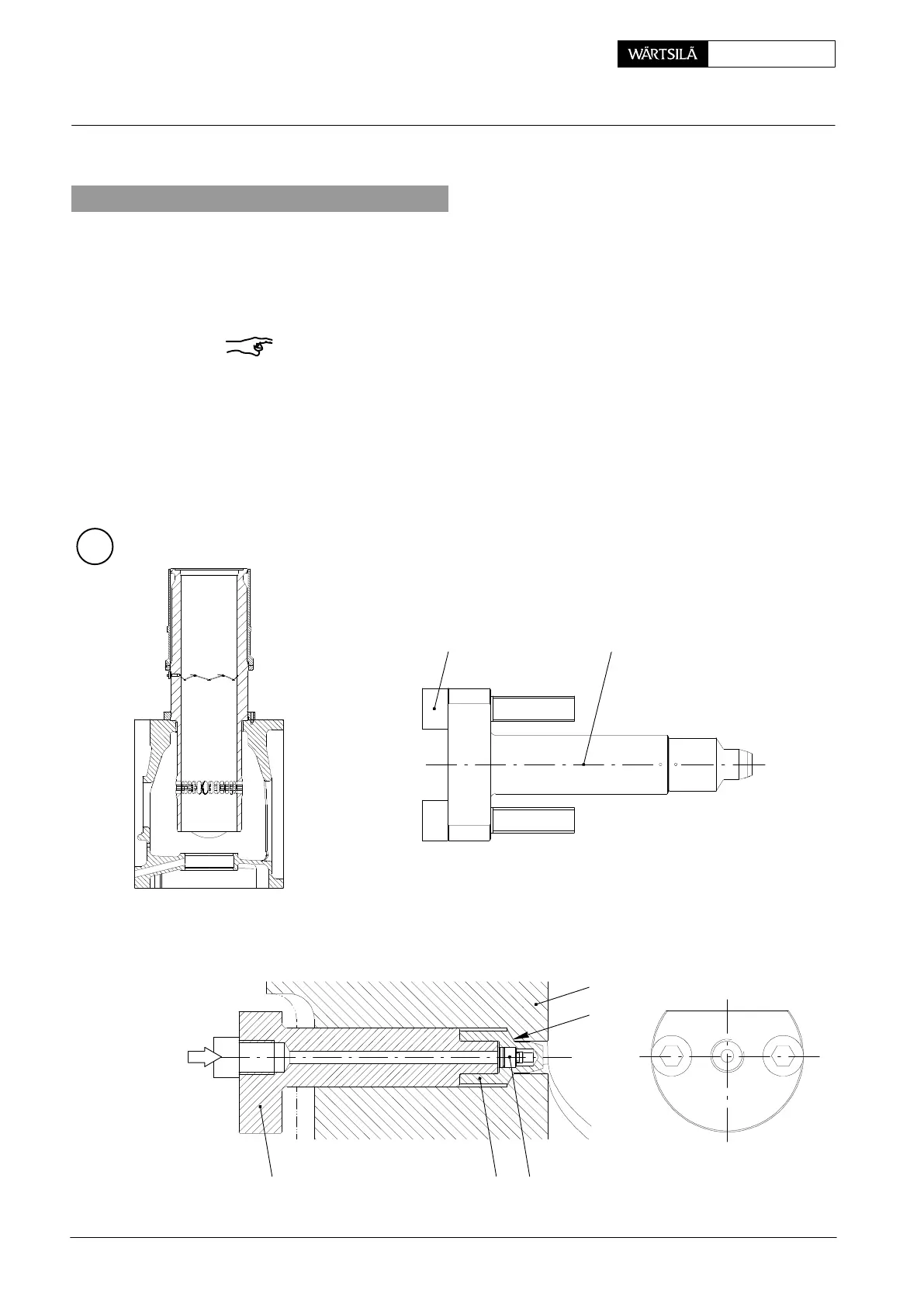

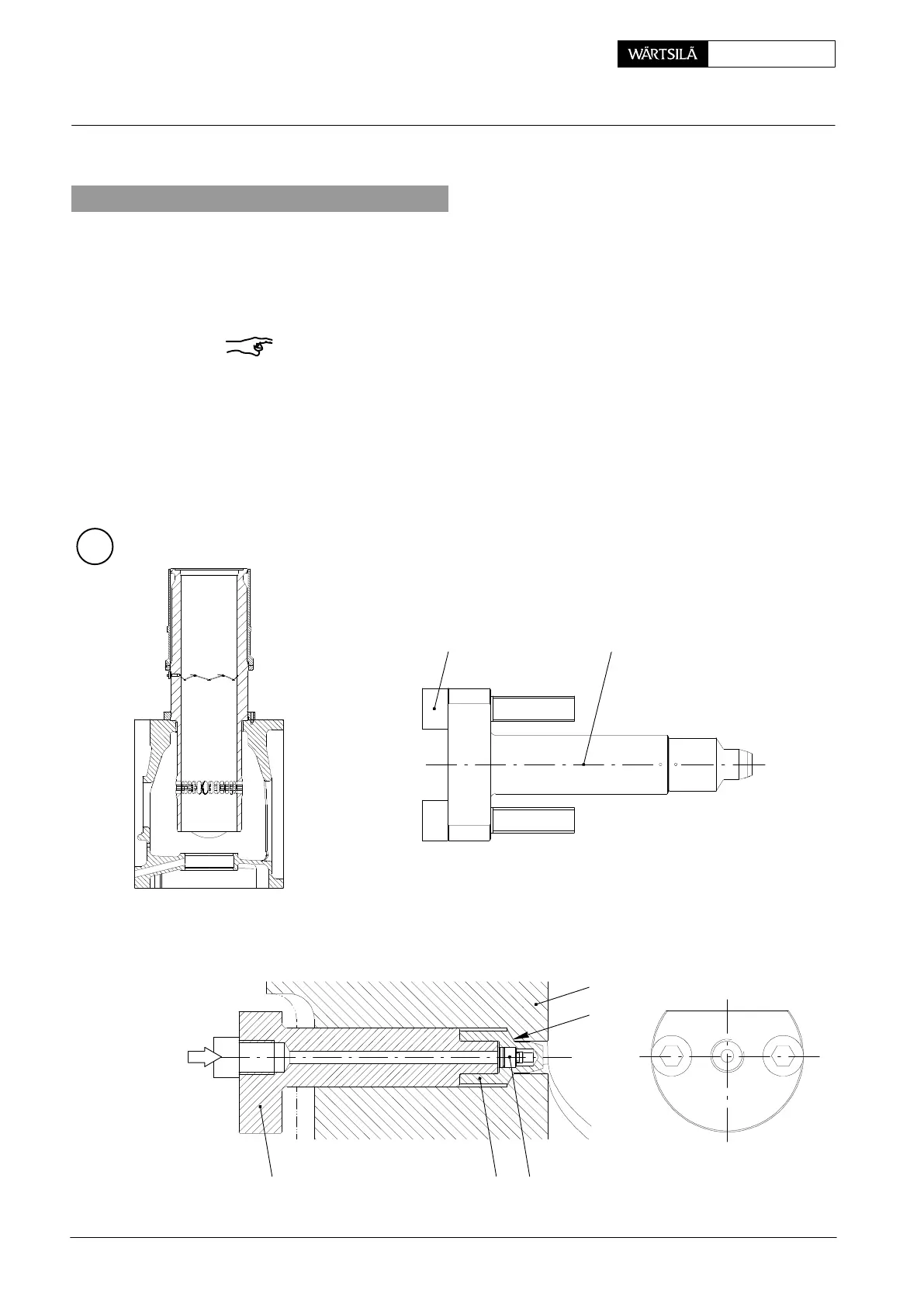

2. Removal and fitting of lubricating quill

⇒ Loosen Allen screws 9, nuts of screw-in union 10 and angle union 11 (Fig. ’A’).

Disconnect lubricating oil pipe 12 and protect it against any damages and en-

tering of dirt.

⇒ Remove lubricating quill.

Remark: The assembly of nozzle tip / nozzle holder is based on the press fit de-

sign. The lubricating quill must be replaced as a whole unit, i.e. nozzle tip 6

with non-return valve 8 inserted and holder 7.

D When refitting the lubricating quill, the sealing surface ’DF’ must be clean and

undamaged, as it seals metallically. Moreover, the proper seat angles in the

cylinder liner (120_) and on the nozzle tip (114_) differs slightly. Therefore, do

not use any gasket between cylinder liner 1 and nozzle tip 6!

D Tighten the oiled Allen screws 9 with a torque of 10 Nm.

B

7

WCH00112

1

DF

68

59

2011 / Pulse Jet

Lubricating Quill with Pulse Jet Lubricatio

Loading...

Loading...